|

Automatic Part Removal Using Ejector Pins like injection moulding. January 17, 2018 12:12PM |

Registered: 6 years ago Posts: 9 |

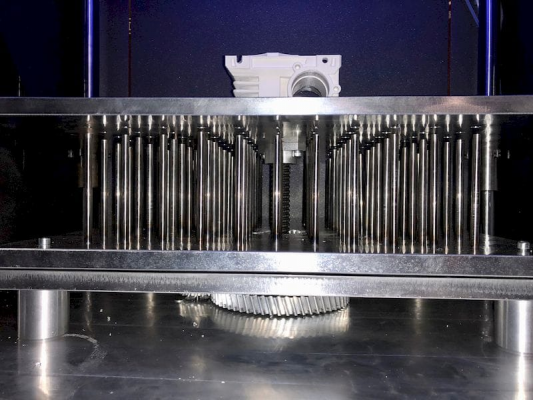

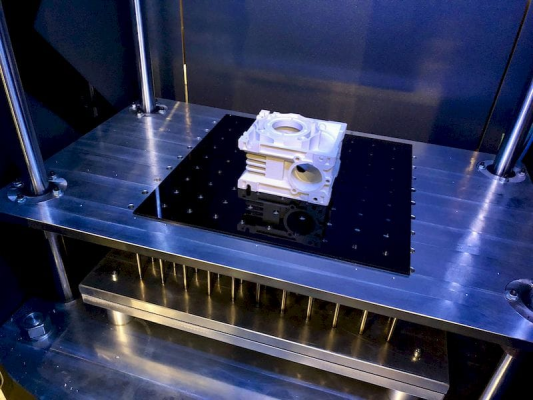

I came across this article on automatic part removal : [www.fabbaloo.com].

I think it could be very interesting to remove the parts from the print bed. Using pins at an angle could even help slide the part of the bed into a small bin.

What do you guys think?

I think it could be very interesting to remove the parts from the print bed. Using pins at an angle could even help slide the part of the bed into a small bin.

What do you guys think?

|

Re: Automatic Part Removal Using Ejector Pins like injection moulding. January 18, 2018 03:55AM |

Registered: 8 years ago Posts: 601 |

Will the holes create surface defects? Will surface adhesion be affected?

I would prefer to use well dialed in PrintBite or similar that releases the part at low temperatures, and then you can just use a ram to push parts off. Would be cheaper to make aswell and could use printed parts and mechanisms

I would prefer to use well dialed in PrintBite or similar that releases the part at low temperatures, and then you can just use a ram to push parts off. Would be cheaper to make aswell and could use printed parts and mechanisms

|

Re: Automatic Part Removal Using Ejector Pins like injection moulding. January 20, 2018 04:24AM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Automatic Part Removal Using Ejector Pins like injection moulding. January 20, 2018 09:35AM |

Registered: 7 years ago Posts: 507 |

|

Re: Automatic Part Removal Using Ejector Pins like injection moulding. January 23, 2018 03:36AM |

Registered: 8 years ago Posts: 601 |

Quote

Trakyan

Following off the use of a ram idea, why not use the x assembly as a ram to knock the print off the bed? Should be just a G-code post script away for most printers and as long as you have a surface that doesn't stick the print down too well it shouldn't harm the printer.

The potential to harm the printer is certainly there though... If it was me I'd like to beef up the X assembly to make sure it wasn't knocked off its path. Potentially a very good use for closed loop motors.

I have also seen printers which have a stack of print beds held in place by a lip on each side, but not at the front. When the print is done the first bed is pushed off, to be replaced by the second (pushed up by springs). The ram in this instance could again be an X or XY gantry to push the print beds off.

Sorry, only registered users may post in this forum.