Home

>

Library - projects, parts, arts, docs, and policy

>

Let's design something! (I've got an idea ...)

>

Topic

Making larger parts suitable for higher RPM's

Posted by scoot

|

Making larger parts suitable for higher RPM's January 29, 2018 05:23PM |

Registered: 6 years ago Posts: 11 |

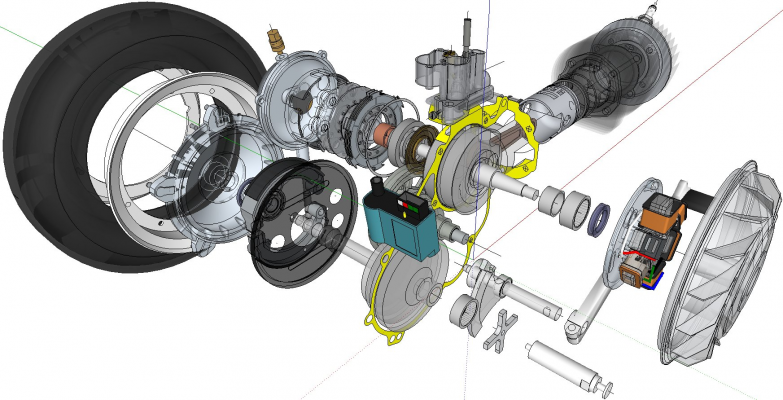

Hello, I am a noob and have just finished assembling my first printer, an FLSUN i3 clone. One of the reasons 3D printing attracted me is its potential to support my other hobbies, namely pattern work for my home foundry which in turn supports my love of old 2 stroke geared Vespa scooters. Now I am imagining all sorts of applications, including a scale motor like this one a friend in Britain is currently modeling:

.

The fan that bolts to the flywheel is available in many aftermarket upgrade varieties, but is usually CNC'd from billet and rather expensive. Making as a print offers lighter weight if desired as well as the possibility of editing the vane geometry to try for most effective blower that uses the least amount of power. There are many competing designs & claims on the market, a few shown in the enclosed pics.

My question is whether it's possible to tell any of the slicers available that laying the strands essentially radially is the highest priority? Does it seem that this would yield the strongest part? The fan is about 195 mm in diameter and might see 10,000 RPM from a hopped up motor on a good day.

Any suggestions for slicing and what strong filament a noob might try(have heated bed) would be greatly appreciated. Thanks!

.

The fan that bolts to the flywheel is available in many aftermarket upgrade varieties, but is usually CNC'd from billet and rather expensive. Making as a print offers lighter weight if desired as well as the possibility of editing the vane geometry to try for most effective blower that uses the least amount of power. There are many competing designs & claims on the market, a few shown in the enclosed pics.

My question is whether it's possible to tell any of the slicers available that laying the strands essentially radially is the highest priority? Does it seem that this would yield the strongest part? The fan is about 195 mm in diameter and might see 10,000 RPM from a hopped up motor on a good day.

Any suggestions for slicing and what strong filament a noob might try(have heated bed) would be greatly appreciated. Thanks!

|

Re: Making larger parts suitable for higher RPM's August 27, 2021 09:20AM |

Registered: 12 years ago Posts: 1,450 |

I am a little confused here (it may be because of the 1960s) but can you clarify whether you want to make a fan for a scale model motor, a pattern for a fan for a scale model or full-size motor, or a 3d printed fan?

I am assuming that it is a pattern to sand cast a full-size fan that you want. Although I can't speak for all cases, from the designs I have created, I think that simply setting the number of layers in the wall will result in the near-optimal alignment of the plastic. You may have problems with getting the surface sufficiently smooth for withdrawal of the pattern and may have to increase the draft a little.

If your intention is to 3D print the actual working fan: While I won't tell you not to, I think I would anticipate much swearing, the sound of fans exploding, and blood, sweat and tears.

Mike

Edited 1 time(s). Last edit at 08/27/2021 09:22AM by leadinglights.

I am assuming that it is a pattern to sand cast a full-size fan that you want. Although I can't speak for all cases, from the designs I have created, I think that simply setting the number of layers in the wall will result in the near-optimal alignment of the plastic. You may have problems with getting the surface sufficiently smooth for withdrawal of the pattern and may have to increase the draft a little.

If your intention is to 3D print the actual working fan: While I won't tell you not to, I think I would anticipate much swearing, the sound of fans exploding, and blood, sweat and tears.

Mike

Edited 1 time(s). Last edit at 08/27/2021 09:22AM by leadinglights.

|

Re: Making larger parts suitable for higher RPM's August 27, 2021 10:09AM |

Registered: 11 years ago Posts: 5,780 |

I think you could print a full size rotor like that and run it at 10krpm. I printed some smaller rotors that I copied from a CPAP blower and ran them at over 20krpm without incident. They came off the printer requiring no tweaks to balance them and the motor ran very smoothly.

There are some slicer tricks you can use to get the blades to print the way you want. In Prusa slicer you can specify things like fill density at specific z height ranges. I would use wide line width and thick layers, and specify multiple perimeters so that the blades print as perimeters without any infill. Fillet all corners, especially inside corners, so that you're not creating any stress risers.

Your biggest concern may be the temperature it has to survive and the potential for getting gas and oil spilled on the plastic.

Edited 1 time(s). Last edit at 08/28/2021 09:03AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

There are some slicer tricks you can use to get the blades to print the way you want. In Prusa slicer you can specify things like fill density at specific z height ranges. I would use wide line width and thick layers, and specify multiple perimeters so that the blades print as perimeters without any infill. Fillet all corners, especially inside corners, so that you're not creating any stress risers.

Your biggest concern may be the temperature it has to survive and the potential for getting gas and oil spilled on the plastic.

Edited 1 time(s). Last edit at 08/28/2021 09:03AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Making larger parts suitable for higher RPM's April 09, 2023 08:56AM |

Registered: 1 year ago Posts: 26 |

Priline PC-CF (available on Amazon) is relatively easy to print and is pretty strong stuff and may hold up. It is what I use for automotive applications.

At 10k rpm watch out for off balance. Much will come down to design, blade thickness, make sure to radius fillet interface where vanes meet rotor. Try to reduce mass towards the outer diameter.

Good luck and post some pics when you get it done.

Edited 1 time(s). Last edit at 04/09/2023 09:09AM by brokencase.

At 10k rpm watch out for off balance. Much will come down to design, blade thickness, make sure to radius fillet interface where vanes meet rotor. Try to reduce mass towards the outer diameter.

Good luck and post some pics when you get it done.

Edited 1 time(s). Last edit at 04/09/2023 09:09AM by brokencase.

Sorry, only registered users may post in this forum.