Home

>

Library - projects, parts, arts, docs, and policy

>

Let's design something! (I've got an idea ...)

>

Topic

Magnetic ball joint: square tube mount ?

Posted by RonaldM

|

Magnetic ball joint: square tube mount ? January 13, 2022 04:07PM |

Registered: 2 years ago Posts: 2 |

Hi everybody,

my intention is as follows, and I need specific advice to accomplish it:

to mount a square tube (outer length of 'square' 3.5 cm, tube length 8 cm, weight 280 gr approx. in equal distribution across tube) via a threaded cup magnet screwed directly onto the ball of a magnetic ball joint ("MBJ"). The weight of magnet is included in the 280 gr. Magnet is comparatively thin and will sit directly on the ball, which has adequate threaded stud -- no unnecessary lever here. (In contrast, the tube constitutes considerable lever.)

My question is:

Which MINIMUM SIZE of MBJ is required so that the load described above is hold securely in place, regardless of ball's position in joint ?

(Assuming there's no particular additional force, neither supporting nor disruptive, just the 'usual background conditions' such as gravity.)

Of course, the answer depends on type of MBJ.

However, searching the internet, there seems to be only one kind of MBJ commercially available anyway, but in several sizes starting at 8 mm ball diameter.

Anyone here who can offer some good advice ?

my intention is as follows, and I need specific advice to accomplish it:

to mount a square tube (outer length of 'square' 3.5 cm, tube length 8 cm, weight 280 gr approx. in equal distribution across tube) via a threaded cup magnet screwed directly onto the ball of a magnetic ball joint ("MBJ"). The weight of magnet is included in the 280 gr. Magnet is comparatively thin and will sit directly on the ball, which has adequate threaded stud -- no unnecessary lever here. (In contrast, the tube constitutes considerable lever.)

My question is:

Which MINIMUM SIZE of MBJ is required so that the load described above is hold securely in place, regardless of ball's position in joint ?

(Assuming there's no particular additional force, neither supporting nor disruptive, just the 'usual background conditions' such as gravity.)

Of course, the answer depends on type of MBJ.

However, searching the internet, there seems to be only one kind of MBJ commercially available anyway, but in several sizes starting at 8 mm ball diameter.

Anyone here who can offer some good advice ?

|

Re: Magnetic ball joint: square tube mount ? January 14, 2022 10:16AM |

Registered: 2 years ago Posts: 2 |

Hello again !

OK, maybe you could help me with a basic question closely related to this topic:

The specs of magnetic ball joints usually include a parameter 'Maximum Holding Force' (MHF), with a value of 10 N, for example.

What, exactly, does MHF mean in this context ?

For example:

- Is it the (smallest) force necessary to change ball's position in joint (ball-movement force) ?

- Is it the (smallest) force necessary to radially pull the ball out of joint (radial-connection-break force) ?

- Something else, and if, what ?

Edited 1 time(s). Last edit at 01/14/2022 10:18AM by RonaldM.

OK, maybe you could help me with a basic question closely related to this topic:

The specs of magnetic ball joints usually include a parameter 'Maximum Holding Force' (MHF), with a value of 10 N, for example.

What, exactly, does MHF mean in this context ?

For example:

- Is it the (smallest) force necessary to change ball's position in joint (ball-movement force) ?

- Is it the (smallest) force necessary to radially pull the ball out of joint (radial-connection-break force) ?

- Something else, and if, what ?

Edited 1 time(s). Last edit at 01/14/2022 10:18AM by RonaldM.

|

Re: Magnetic ball joint: square tube mount ? January 15, 2022 05:33AM |

Registered: 12 years ago Posts: 1,450 |

I am not sure that I have seen a stated definition and the meaning "Maximum Holding Force" depends on how the joint is constructed.

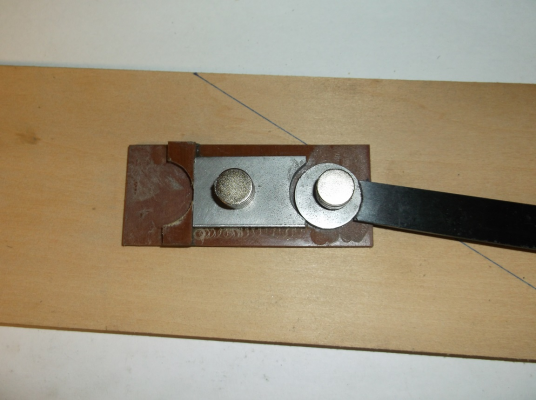

Counter-intuitively, the use of iron or steel seats for the ball is a really bad design choice for these joints. This is clear in the picture below. Full forum entry at [reprap.org] but I have put a picture showing this partial failure here

Since there is some movement with quite a small force, this is clearly a bad thing for 3D printers. A nonmagnetic seat such as PTFE will ensure that the joint is firm

Mike

Edited 1 time(s). Last edit at 01/15/2022 08:01AM by leadinglights.

Counter-intuitively, the use of iron or steel seats for the ball is a really bad design choice for these joints. This is clear in the picture below. Full forum entry at [reprap.org] but I have put a picture showing this partial failure here

Since there is some movement with quite a small force, this is clearly a bad thing for 3D printers. A nonmagnetic seat such as PTFE will ensure that the joint is firm

Mike

Edited 1 time(s). Last edit at 01/15/2022 08:01AM by leadinglights.

Sorry, only registered users may post in this forum.