[Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more

Posted by eckertech

|

[Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more March 18, 2013 04:08PM |

Registered: 13 years ago Posts: 106 |

We have ecksbot DIY kits & fully assembled machines, custom all metal hot ends and conversion kits, 3mm ABS filament, Kapton sheets with adhesive backing, power supplies, stepper motors, eckstruder kits, plastic parts and much more.

Visit us at http://www.eckertech.com for more information.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

Visit us at http://www.eckertech.com for more information.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

|

Re: [Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more March 27, 2013 10:47AM |

Registered: 13 years ago Posts: 106 |

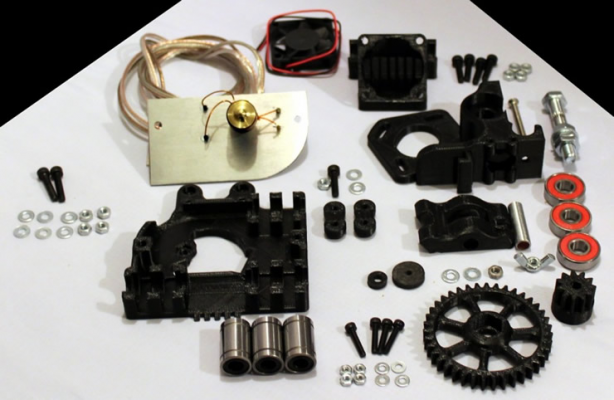

The ecksbot DIY kit has been packaged to EckerTech standards containing high quality components to match the high quality of EckerTech printed parts. From the EckerTech all metal hot-end to long lasting precision ground hardened chromed linear motion rod the ecksbot is designed for durability.

The average ecksbot user can assemble, calibrate and start printing within 2 days of receiving their kit.

For more information please visit, http://www.eckertech.com/ecksbot/.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

The average ecksbot user can assemble, calibrate and start printing within 2 days of receiving their kit.

For more information please visit, http://www.eckertech.com/ecksbot/.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

|

Re: [Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more April 03, 2013 04:11PM |

Registered: 13 years ago Posts: 106 |

Our NEW Hot end conversion kit for Nema 17 Prusa style machines converts any machine using the standard Prusa style X carriage with Nema 17 extruder to the active cooled all metal ecksbot standard.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

|

Re: [Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more April 05, 2013 02:02PM |

Registered: 13 years ago Posts: 106 |

The Eckertech hot-end is a two part, all metal design capable of both low speed, low volume and high speed, high volume prints. By removing the need for a PTFE barrier and by employing a large heatsink with active cooling, the hot-end is capable of very high heats without the worry of heat migration or heat related jams, no matter your choice of 3mm plastic (PLA or ABS). In fact, we have never experienced a jam in our hot-ends that wasn’t caused by foreign debris! Machined from quality material to tight tolerances, the Eckertech hot-end is a strong, durable design capable of printing the most demanding of prints. Whether printing at a rough 0.4mm vertical resolution or an ultra-fine, ultra-detailed 0.05mm (50 micron), the Eckertech hot-end can do it all.

Included in package

1 - Assembled hot-end (0.45mm nozzle size)

1 - Extruder Fan

1 - Extruder cleaning kit (copper tube & nozzle cleaner)

Note: Custom nozzle sizes available upon request at no additional cost. Plastic parts not included.

High Temperature:

The Eckertech all metal construction allows the hot-end to operate at extreme temperatures that are unattainable with PTFE liner based designs. The hot-end can operate at temperatures in excess of 300 degrees Celsius without worrying about jamming due to heat migration or a melted PTFE liner.

Active Cooling:

Zero danger of heat migration and extruder jam common to most PTFE barrier, and low profile hot-ends. With the use of a low thermal transfer stainless steel filament guide, and a large, actively cooled aluminum heatsink, we are able to keep the temperature beyond the heatsink below 60° Celsius and well below the point where either ABS of PLA become sticky or begin to swell. In fact, one of our design requirements was to create a hot-end that could be heated to a temperature above that required to print and sit for 1 hour without printing, and not jam.

Sturdy All Metal construction:

Designed around a two part construction, the all metal hot-end has a high thermal transfer brass heating barrel and a low thermal transfer stainless steel filament guide. This two part design, in conjunction with a large aluminum heatsink and active cooling gives rise to the ideal heating system for a 3D printer; A highly reactive heating chamber with plenty of heat capacity, and finite thermal break point above which keeps the filament nice and cool.

The large aluminum heatsink also serves a very important second function; it creates a wide stance, 3 point mounting system. The 3 point mounting system creates a strong, sturdy and durable structure that can withstand the roughest of users. Let’s be honest, sometimes we accidentally use our hot-ends as battering rams. Like clicking home on the wrong axis while printed parts are still on the bed, or printing so thick that the extruder grinds through previous layers. While we don’t recommend trying these things we do know that compared to other hot-ends our nozzle will still work after crashing through parts.

Precision machined:

All components are precision machined to tight tolerances and all areas that are in contact with plastic filament are machine reamed for a polished finish. Our strict attention to quality leads to highly repeatable printing results across machine builds. When used in conjunction with out stock slic3r and skeinforge settings, prints are 100% repeatable.

360° degree heater barrel:

Unlike the common single resistor side mount hot-ends, the Eckertech hot-end employs a dual channel, 360° design that provides a uniform heat profile that provides more consistent printing. The dual channels are wrapped in a professional grade nichrome heating wire, double wound with a 2mil kapton insulator. This isn’t your regular everyday nichrome wire! Using nichrome and providing a 360° wrap means that the hot-end is not only very consistent, but is also more reactive than resistor based designs.

High flow rate, No filament jams due to heat migration:

Capable of running at 2.5mm/sec of raw 3mm diameter filament intake reaching the equivalent of 111mm/sec filament output through a 0.45mm aperture. As a working example we regularly print at 120mm/sec infill with a 0.3mm layer height and 0.45mm extrusion width.

Easy cleaning with included cleaning kit:

No disassembly or small fires required. Simply use the included cleaning kit to quickly and thoroughly clean the inside of hot-end from top to bottom, including the tricky bit of cleaning the orifice.

Works with both 3mm ABS and 3mm PLA:

With its sturdy design, ability to work at high temperatures, and easy cleaning procedure; filament changes between PLA and ABS and back again are a snap. It can be as simple as heating to ABS temperature and running the filament until the old plastic is no longer present. Or if you are in a hurry, simply clean the hot-end using the included cleaning kit and you can change over in minutes without a trace of the old plastic.

Proven Track Record:

With 7 iterations, countless test hours, and over 20,000 hours of printing across our production machine fleet; the Eckertech hot-end is a proven workhorse.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

|

Re: [Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more April 15, 2013 02:08PM |

Registered: 13 years ago Posts: 106 |

This PSU boasts an extra 60Watts of overhead and has a lot more protection built in. If an over current is detected due to short or if the unit gets too hot due to a lack of ventalation, the unit will set it's self into protection mode. In protection mode, the unit will power down and stay powered down until the power is cycled.

Active cooling

The unit also sports a heat sensing circuit and active cooling fan. The heat sensor determines when the unit is getting warm or cool and activates or deactivates the fan accordingly. This way the cooling fan doesn't run constantly. In practice, we find that the fan will only run when the output current is greater than 12Amps for an extended period of time.

Sturdy design

The chasis is a two piece design with an all aluminum frame and cover. The two components are all made from 1.5mm punch presses aluminum and will stand up to much more wear and tear than most PSUs.

Specifications/features:

- 12V, 25Amp, 300Watt

- 110/220V switchable input voltages for intercontinental adaptablility

- Active cooling with heat sensor

- Fused for overcurrent protection on the mains

- very sturdy thick grade aluminum build

- Built in auto shutdown when a short is detected or an overheat occurs, to protect the PSU from outright failure

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

Active cooling

The unit also sports a heat sensing circuit and active cooling fan. The heat sensor determines when the unit is getting warm or cool and activates or deactivates the fan accordingly. This way the cooling fan doesn't run constantly. In practice, we find that the fan will only run when the output current is greater than 12Amps for an extended period of time.

Sturdy design

The chasis is a two piece design with an all aluminum frame and cover. The two components are all made from 1.5mm punch presses aluminum and will stand up to much more wear and tear than most PSUs.

Specifications/features:

- 12V, 25Amp, 300Watt

- 110/220V switchable input voltages for intercontinental adaptablility

- Active cooling with heat sensor

- Fused for overcurrent protection on the mains

- very sturdy thick grade aluminum build

- Built in auto shutdown when a short is detected or an overheat occurs, to protect the PSU from outright failure

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

|

Re: [Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more June 17, 2013 02:03PM |

Registered: 13 years ago Posts: 106 |

With over 3000 lbs of ABS and over 1000 lbs of PLA filament printed in our shop alone (over the last 4 years) this all metal hot end is a proven workhorse.

The conversion kit comes with everything you need to update your Sells Mendel to the EckerTech Hot End standard. This kit is available as a complete kit including hardware, plastic parts and hot end at http://www.eckertech.com/mendel-hot-end-conversion-kit.

This Hot End is also available on its own here: http://www.eckertech.com/mendel-hot-end/. With the plastic parts STL files available for download here: http://www.thingiverse.com/thing:105053

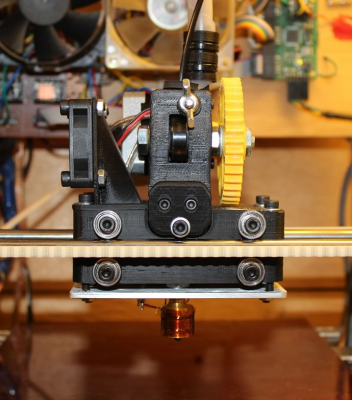

As well as adapting the extruder block to fit our hot end we made some improvements to the carriage:

1. We repositioned the lower carriage rear bearing mounts after finding out that they were misaligned in the original files?!?

2. We replaced the original lower carriage tower with a flat printed independent unit which is much stronger.

3. We added belt alignment notches to the tower and blocks to the clamps to hold the belt in proper vertical position while clamping it tight. Eliminates the fiddly part of maintaining vertical alignment of the belt while you tighten it into place.

4. We adapted the upper carriage to fit our clip in eckstruder.

5. We covered the top gear side of upper carriage to better direct the airflow over the heatsink.

6. We updated the eckstruder to the new version wire capture model with spiral wrap tubing.

7. We front mounted the M3X25mm hot end extension locking bolts for easy access.

8. We notched the eckstruder base to provide a clip in attachment for the fan housing.

9. We counter bored the upper carriage to extend the heatsink mounting bolts for attachment to the heatsink.

10. We added nut captures to the outer clamping bolts on the lower carriage for easier tension adjustments of the bearings, as well as counter bored the bearing bolt holes to provide better clearance for the heatsink.

We also added spiral wrap tubing adaptors to clean up the wiring.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

|

Re: [Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more June 24, 2013 03:44PM |

Registered: 13 years ago Posts: 106 |

We get asked all the time about long prints. So, here is a short video of a dragon we printed which took 14 hours.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

|

Re: [Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more June 27, 2013 07:22AM |

|

Re: [Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more June 27, 2013 12:39PM |

Registered: 13 years ago Posts: 106 |

The time of each print is affected by many factors but the 5 major factors that affected this print are layer height, infill solidity, support, extrusion speeds and the size of the object.

The layer height is 0.15mm (150 microns), the infill solidity is 25%, the support was 80% flow rate, we printed at 60mm/s and the object before support was added is 135mm x 103mm x 80mm.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

The layer height is 0.15mm (150 microns), the infill solidity is 25%, the support was 80% flow rate, we printed at 60mm/s and the object before support was added is 135mm x 103mm x 80mm.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

|

Re: [Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more August 28, 2013 03:58PM |

Registered: 13 years ago Posts: 106 |

Here is the link to the dragon video https://www.youtube.com/watch?v=kUaVnFvd5UI

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

|

Re: [Canada, US & worldwide] ecksbot DIY kits, hot ends, ABS filament and more August 28, 2013 04:02PM |

Registered: 13 years ago Posts: 106 |

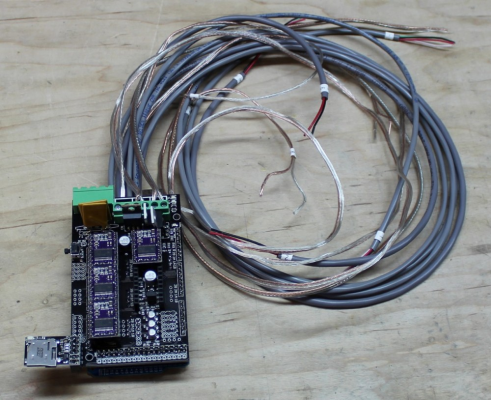

The ecksbot Ramps 1.4 electronics comes complete with wiring harness pre-soldered into the Ramps board. The attached wiring is pre sized and numbered for easy installation using the ecksbot wiring method (click here) and can also be used for other RepRap printers if you don't mind our wiring configuration and wire lengths.

What's included?

• Fully assembled RAMPS 1.4 built on a black PCB because it just looks better that way

• Arduino Mega 2560 with USB cord

• 4 Genuine DRV8825 Pololu's built on 4 layer, 2oz copper PCB's for better heatsinking

• 1 SD Ramps addon for autonomous printing (printer not attached, micro SD not included)

• Full ecksbot wiring harness

What's Recommended?

• We recommend adding terminal blocks to your order, option found above, if you prefer a screwdriver over a soldering iron

. These terminal blocks are rated to 24 amp's and are perfect for connecting 2 wires together. We use these blocks in all of our kits and fully assembled machines. Remember to make sure that your connections are tight!

. These terminal blocks are rated to 24 amp's and are perfect for connecting 2 wires together. We use these blocks in all of our kits and fully assembled machines. Remember to make sure that your connections are tight! • We recommend a plastic housing for the electronics with a cooling fan and ventilation system. We have one in the works which will be made available at a later date for purchase on our website or downloadable through thingiverse.

[www.eckertech.com]

[blog.eckertech.com]

[forum.eckertech.com]

Sorry, only registered users may post in this forum.