Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid)

Posted by reifsnyderb

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) August 21, 2010 11:29PM |

Registered: 15 years ago Posts: 537 |

Hello,

I just checked on pricing and the PEEK block is the real problem. At smallparts.com, a 3/8" x 3" x 3" piece of PEEK is $41.55. I would have to charge around $15.00, or more, for the PEEK block alone.

If, instead of a PEEK block, I were to make a kit with a PTFE insulator, brass nozzle (as per those specifications), and a PEEK washer, I could get the price down to around $20.00 per kit. Instead of using a block of PEEK, a metal plate would be made that would retain the brass nozzle. (The standard MakerBot MK4 retainer washer could probably be used and drilled out to a larger size.) The PEEK washer would insulate the metal plate from the nozzle.

However, I would need to have enough interest to make a batch (at least 10) of those parts kits in order to be able to hold the $20.00 quote per kit. Otherwise, for a one-off, the price would be much much higher.

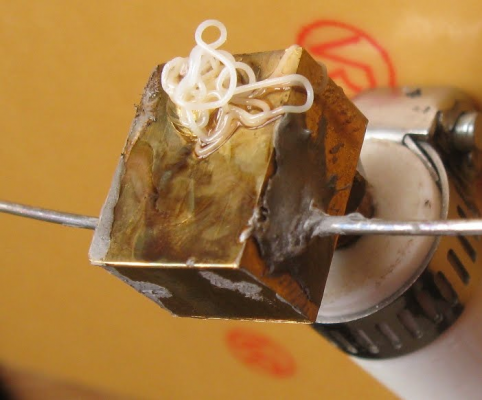

I attached a picture of a test nozzle, that I built, that uses a long PEEK thermal barrier (lined with a PTFE sleeve), a short nozzle (very similar to the one in the URL you posted, and a resistor-based heater element. There is a PEEK insulating washer located under the heater element. Not shown is a metal plate that would go over the insulating washer and retain the hole assembly. I sent it out to somebody for testing and it worked quite well.

Regards,

Brian

Greg Frost Wrote:

-------------------------------------------------------

> Can you make the parts for this:

> [reprap.org]

> (PEEK block, PTFE insulator, brass nozzle)?

> If so, how much would you charge?

I just checked on pricing and the PEEK block is the real problem. At smallparts.com, a 3/8" x 3" x 3" piece of PEEK is $41.55. I would have to charge around $15.00, or more, for the PEEK block alone.

If, instead of a PEEK block, I were to make a kit with a PTFE insulator, brass nozzle (as per those specifications), and a PEEK washer, I could get the price down to around $20.00 per kit. Instead of using a block of PEEK, a metal plate would be made that would retain the brass nozzle. (The standard MakerBot MK4 retainer washer could probably be used and drilled out to a larger size.) The PEEK washer would insulate the metal plate from the nozzle.

However, I would need to have enough interest to make a batch (at least 10) of those parts kits in order to be able to hold the $20.00 quote per kit. Otherwise, for a one-off, the price would be much much higher.

I attached a picture of a test nozzle, that I built, that uses a long PEEK thermal barrier (lined with a PTFE sleeve), a short nozzle (very similar to the one in the URL you posted, and a resistor-based heater element. There is a PEEK insulating washer located under the heater element. Not shown is a metal plate that would go over the insulating washer and retain the hole assembly. I sent it out to somebody for testing and it worked quite well.

Regards,

Brian

Greg Frost Wrote:

-------------------------------------------------------

> Can you make the parts for this:

> [reprap.org]

> (PEEK block, PTFE insulator, brass nozzle)?

> If so, how much would you charge?

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 01, 2010 11:20PM |

Registered: 14 years ago Posts: 30 |

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 03, 2010 10:31AM |

Registered: 15 years ago Posts: 537 |

Hello,

Sorry about the late reply. Please e-mail me at reifsnyderb -at- hotmail -dot- com, with your address, and I'll send you a new one.

Regards,

Brian

Katai Wrote:

-------------------------------------------------------

> I ordered a Hybrid insulator a while ago, and it

> seems that my ABS filled up the space between the

> PTFE and the PEEK and pushed the retaining ring

> out. I put it back together, but the same thing

> just happened again. Any ideas what I can do with

> this?

Sorry about the late reply. Please e-mail me at reifsnyderb -at- hotmail -dot- com, with your address, and I'll send you a new one.

Regards,

Brian

Katai Wrote:

-------------------------------------------------------

> I ordered a Hybrid insulator a while ago, and it

> seems that my ABS filled up the space between the

> PTFE and the PEEK and pushed the retaining ring

> out. I put it back together, but the same thing

> just happened again. Any ideas what I can do with

> this?

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 03, 2010 10:33AM |

Registered: 15 years ago Posts: 537 |

PM Sent.

Katai Wrote:

-------------------------------------------------------

> I ordered a Hybrid insulator a while ago, and it

> seems that my ABS filled up the space between the

> PTFE and the PEEK and pushed the retaining ring

> out. I put it back together, but the same thing

> just happened again. Any ideas what I can do with

> this?

Katai Wrote:

-------------------------------------------------------

> I ordered a Hybrid insulator a while ago, and it

> seems that my ABS filled up the space between the

> PTFE and the PEEK and pushed the retaining ring

> out. I put it back together, but the same thing

> just happened again. Any ideas what I can do with

> this?

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 15, 2010 07:32PM |

Registered: 14 years ago Posts: 356 |

Hello :-)

I do need a reliable extruder and looks to me that the way to go is "PTFE inside brass barrel" :-)

I did rebuild my extruder with your "power resistor heater block" and it works very well!! Is much better than using nichrome wire. Just the power resistor needs to have lower value, lower than 5R6, maybe 4R7.

My problem is now backflow of ABS or PLA, and it even flows between PTFE and brass barrel!! I am sure that with PTFE inside brass barrel, it will not flow outside. I will take a picture later showing the backflow.

I think you should do an extruder like this one, and yes, forget the PEEK!! I had used washers directly to brass barrel and it works perfectly! I even printed my all Mendel with this extruder:

(Spring extruder)

And maybe even the M7 thread on PTFE and brass barrel is not needed. Just PTFE inside brass barrel.

I need such a reliable extruder and I am ready to pay, please produce it and show here in pictures.

Edited 1 time(s). Last edit at 09/15/2010 07:35PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

I do need a reliable extruder and looks to me that the way to go is "PTFE inside brass barrel" :-)

I did rebuild my extruder with your "power resistor heater block" and it works very well!! Is much better than using nichrome wire. Just the power resistor needs to have lower value, lower than 5R6, maybe 4R7.

My problem is now backflow of ABS or PLA, and it even flows between PTFE and brass barrel!! I am sure that with PTFE inside brass barrel, it will not flow outside. I will take a picture later showing the backflow.

I think you should do an extruder like this one, and yes, forget the PEEK!! I had used washers directly to brass barrel and it works perfectly! I even printed my all Mendel with this extruder:

(Spring extruder)

And maybe even the M7 thread on PTFE and brass barrel is not needed. Just PTFE inside brass barrel.

I need such a reliable extruder and I am ready to pay, please produce it and show here in pictures.

Edited 1 time(s). Last edit at 09/15/2010 07:35PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 15, 2010 09:42PM |

Registered: 15 years ago Posts: 537 |

Hello,

Is it possible that the brass barrel got loose? I would try to tighten the hose clamp a little more...maybe even when the PTFE is still warm.

I have not pursued making another type of extruder hot end as both the Mk5 is out and there really wasn't a good consensus on the thread that I posted regarding making another type of extruder hot end.

Regards,

Brian

casainho Wrote:

-------------------------------------------------------

> Hello :-)

>

> I do need a reliable extruder and looks to me that

> the way to go is "PTFE inside brass barrel" :-)

>

> I did rebuild my extruder with your "power

> resistor heater block" and it works very well!! Is

> much better than using nichrome wire. Just the

> power resistor needs to have lower value, lower

> than 5R6, maybe 4R7.

>

> [forums.reprap.org]

> ename=resistor_heater_block-jpcasainho-20100915.jp

> g

>

>

> My problem is now backflow of ABS or PLA, and it

> even flows between PTFE and brass barrel!! I am

> sure that with PTFE inside brass barrel, it will

> not flow outside. I will take a picture later

> showing the backflow.

>

> I think you should do an extruder like this one,

> and yes, forget the PEEK!! I had used washers

> directly to brass barrel and it works perfectly! I

> even printed my all Mendel with this extruder:

> [farm3.static.flickr.com]

> bc5bba2_z.jpg

> (Spring extruder)

>

> And maybe even the M7 thread on PTFE and brass

> barrel is not needed. Just PTFE inside brass

> barrel.

>

> I need such a reliable extruder and I am ready to

> pay, please produce it and show here in pictures.

Is it possible that the brass barrel got loose? I would try to tighten the hose clamp a little more...maybe even when the PTFE is still warm.

I have not pursued making another type of extruder hot end as both the Mk5 is out and there really wasn't a good consensus on the thread that I posted regarding making another type of extruder hot end.

Regards,

Brian

casainho Wrote:

-------------------------------------------------------

> Hello :-)

>

> I do need a reliable extruder and looks to me that

> the way to go is "PTFE inside brass barrel" :-)

>

> I did rebuild my extruder with your "power

> resistor heater block" and it works very well!! Is

> much better than using nichrome wire. Just the

> power resistor needs to have lower value, lower

> than 5R6, maybe 4R7.

>

> [forums.reprap.org]

> ename=resistor_heater_block-jpcasainho-20100915.jp

> g

>

>

> My problem is now backflow of ABS or PLA, and it

> even flows between PTFE and brass barrel!! I am

> sure that with PTFE inside brass barrel, it will

> not flow outside. I will take a picture later

> showing the backflow.

>

> I think you should do an extruder like this one,

> and yes, forget the PEEK!! I had used washers

> directly to brass barrel and it works perfectly! I

> even printed my all Mendel with this extruder:

> [farm3.static.flickr.com]

> bc5bba2_z.jpg

> (Spring extruder)

>

> And maybe even the M7 thread on PTFE and brass

> barrel is not needed. Just PTFE inside brass

> barrel.

>

> I need such a reliable extruder and I am ready to

> pay, please produce it and show here in pictures.

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 16, 2010 04:46AM |

Registered: 14 years ago Posts: 356 |

reifsnyderb Wrote:

-------------------------------------------------------

> Hello,

>

> Is it possible that the brass barrel got loose? I

> would try to tighten the hose clamp a little

> more...maybe even when the PTFE is still warm.

Sorry, didn't understand what you mean.

> I have not pursued making another type of extruder

> hot end as both the Mk5 is out and there really

> wasn't a good consensus on the thread that I

> posted regarding making another type of extruder

> hot end.

I think there will never be a consensus. You just need to provide/sell something that works, people will buy it because they need. I think you need to go ahead.

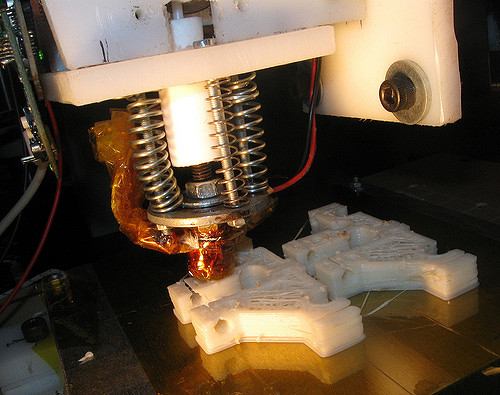

The pictures show a Wade Extruder that never printed ABS, just PLA. ABS needs higher temperature and seems more problematic, because extruder jams as seen on that pictures. Also PLA now jams, as when I took that pictures.

As you can see, with Wade Extruder is possible to use such a washer, to not put PTFE under pressure.

"The PTFE is also inside the brass nozzle, which means that internal extrude pressure tends to seal the join between the two, rather than opening it up." [reprap.org] --- the problem with the backflow of that pictures seem to be that the internal extrude pressure do not tend to seal the joint between PTFE and brass barrel, but instead open it!!

Can you please produce and send me just the brass barrel? I have PTFE, power resistor heater and washers. I just need that brass barrel. I just need the brass barrel as here: [reprap.org] , but without the M7 thread inside! (because I can't do M7 thread on PTFE).

Edited 1 time(s). Last edit at 09/16/2010 04:50AM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> Hello,

>

> Is it possible that the brass barrel got loose? I

> would try to tighten the hose clamp a little

> more...maybe even when the PTFE is still warm.

Sorry, didn't understand what you mean.

> I have not pursued making another type of extruder

> hot end as both the Mk5 is out and there really

> wasn't a good consensus on the thread that I

> posted regarding making another type of extruder

> hot end.

I think there will never be a consensus. You just need to provide/sell something that works, people will buy it because they need. I think you need to go ahead.

The pictures show a Wade Extruder that never printed ABS, just PLA. ABS needs higher temperature and seems more problematic, because extruder jams as seen on that pictures. Also PLA now jams, as when I took that pictures.

As you can see, with Wade Extruder is possible to use such a washer, to not put PTFE under pressure.

"The PTFE is also inside the brass nozzle, which means that internal extrude pressure tends to seal the join between the two, rather than opening it up." [reprap.org] --- the problem with the backflow of that pictures seem to be that the internal extrude pressure do not tend to seal the joint between PTFE and brass barrel, but instead open it!!

Can you please produce and send me just the brass barrel? I have PTFE, power resistor heater and washers. I just need that brass barrel. I just need the brass barrel as here: [reprap.org] , but without the M7 thread inside! (because I can't do M7 thread on PTFE).

Edited 1 time(s). Last edit at 09/16/2010 04:50AM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 16, 2010 06:38AM |

Admin Registered: 17 years ago Posts: 7,879 |

Why don't you just use Brian's hybrid insulator plus the heater block? You then don't need wires, nuts and washers. The PEEK outer casing is strong enough and the PTFE liner keeps it slippery.

Rather than more power you should use a physically smaller resister and a smaller heater block. That reduces the surface area, which is how most of the heat is lost via convection. It also reduces the mass which makes it warm up faster. Aluminium works better than brass because it is lighter, a better conductor and lower thermal mass, so warms quicker as well.

Covering the block with some insulation makes a big difference. Not only does it use less power, but less heat rises up to the insulator so it runs cooler. With an uninsulated block and a heated bed ,the top of the insulator gets too hot for PLA.

[www.hydraraptor.blogspot.com]

Rather than more power you should use a physically smaller resister and a smaller heater block. That reduces the surface area, which is how most of the heat is lost via convection. It also reduces the mass which makes it warm up faster. Aluminium works better than brass because it is lighter, a better conductor and lower thermal mass, so warms quicker as well.

Covering the block with some insulation makes a big difference. Not only does it use less power, but less heat rises up to the insulator so it runs cooler. With an uninsulated block and a heated bed ,the top of the insulator gets too hot for PLA.

[www.hydraraptor.blogspot.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 16, 2010 07:20AM |

Registered: 14 years ago Posts: 356 |

nophead Wrote:

-------------------------------------------------------

> Why don't you just use Brian's hybrid insulator

> plus the heater block? You then don't need wires,

> nuts and washers. The PEEK outer casing is strong

> enough and the PTFE liner keeps it slippery.

?? You are saying this, but did you have one and are you using it daily?

> Rather than more power you should use a physically

> smaller resister and a smaller heater block. That

> reduces the surface area, which is how most of the

> heat is lost via convection. It also reduces the

> mass which makes it warm up faster. Aluminium

> works better than brass because it is lighter, a

> better conductor and lower thermal mass, so warms

> quicker as well.

Let's see if Brian changes from brass to aluminium.

> Covering the block with some insulation makes a

> big difference. Not only does it use less power,

> but less heat rises up to the insulator so it runs

> cooler. With an uninsulated block and a heated bed

> ,the top of the insulator gets too hot for PLA.

Hmm, I did that in past. I still believe that a cooler PTFE/PEEK is important. Would be great if brass get cold in the end!

However I still like the idea of PTFE inside brass barrel, I would like to buy such brass barrel. Did you tested one already?

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> Why don't you just use Brian's hybrid insulator

> plus the heater block? You then don't need wires,

> nuts and washers. The PEEK outer casing is strong

> enough and the PTFE liner keeps it slippery.

?? You are saying this, but did you have one and are you using it daily?

> Rather than more power you should use a physically

> smaller resister and a smaller heater block. That

> reduces the surface area, which is how most of the

> heat is lost via convection. It also reduces the

> mass which makes it warm up faster. Aluminium

> works better than brass because it is lighter, a

> better conductor and lower thermal mass, so warms

> quicker as well.

Let's see if Brian changes from brass to aluminium.

> Covering the block with some insulation makes a

> big difference. Not only does it use less power,

> but less heat rises up to the insulator so it runs

> cooler. With an uninsulated block and a heated bed

> ,the top of the insulator gets too hot for PLA.

Hmm, I did that in past. I still believe that a cooler PTFE/PEEK is important. Would be great if brass get cold in the end!

However I still like the idea of PTFE inside brass barrel, I would like to buy such brass barrel. Did you tested one already?

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 16, 2010 08:26AM |

Admin Registered: 17 years ago Posts: 7,879 |

casainho Wrote:

-------------------------------------------------------

> nophead Wrote:

> --------------------------------------------------

> -----

> > Why don't you just use Brian's hybrid insulator

> > plus the heater block? You then don't need

> wires,

> > nuts and washers. The PEEK outer casing is

> strong

> > enough and the PTFE liner keeps it slippery.

>

> ?? You are saying this, but did you have one and

> are you using it daily?

Yes I tried this with Brain's first prototype and it worked for ABS but eventually the PTFE worked its way up the tube and it jammed. Brian has added a circlip to keep it in place so it should be OK now.

It got too hot for PLA though when I switched to a heated bed, but I didn't have any insulation on the heater block and it is bigger than it should be. I use a smaller resistor and block on HydraRaptor.

>

>

> > Rather than more power you should use a

> physically

> > smaller resister and a smaller heater block.

> That

> > reduces the surface area, which is how most of

> the

> > heat is lost via convection. It also reduces

> the

> > mass which makes it warm up faster. Aluminium

> > works better than brass because it is lighter,

> a

> > better conductor and lower thermal mass, so

> warms

> > quicker as well.

>

> Let's see if Brian changes from brass to

> aluminium.

All you need to make your own is a saw, a drill and a tap. There is no lathe work necessary.

>

>

> > Covering the block with some insulation makes a

> > big difference. Not only does it use less

> power,

> > but less heat rises up to the insulator so it

> runs

> > cooler. With an uninsulated block and a heated

> bed

> > ,the top of the insulator gets too hot for PLA.

>

> Hmm, I did that in past. I still believe that a

> cooler PTFE/PEEK is important. Would be great if

> brass get cold in the end!

Don't understand, the brass is the hot part?

>

> However I still like the idea of PTFE inside brass

> barrel, I would like to buy such brass barrel. Did

> you tested one already?

No I haven't tried that but it should work. I don't like PTFE unless it is totally constrained as it is in my Plumbstruder and Brian's hybrid. I run my Plumstruder at 255C for the first layer and it is 100% reliable. It is quite heavy though.

[www.hydraraptor.blogspot.com]

-------------------------------------------------------

> nophead Wrote:

> --------------------------------------------------

> -----

> > Why don't you just use Brian's hybrid insulator

> > plus the heater block? You then don't need

> wires,

> > nuts and washers. The PEEK outer casing is

> strong

> > enough and the PTFE liner keeps it slippery.

>

> ?? You are saying this, but did you have one and

> are you using it daily?

Yes I tried this with Brain's first prototype and it worked for ABS but eventually the PTFE worked its way up the tube and it jammed. Brian has added a circlip to keep it in place so it should be OK now.

It got too hot for PLA though when I switched to a heated bed, but I didn't have any insulation on the heater block and it is bigger than it should be. I use a smaller resistor and block on HydraRaptor.

>

>

> > Rather than more power you should use a

> physically

> > smaller resister and a smaller heater block.

> That

> > reduces the surface area, which is how most of

> the

> > heat is lost via convection. It also reduces

> the

> > mass which makes it warm up faster. Aluminium

> > works better than brass because it is lighter,

> a

> > better conductor and lower thermal mass, so

> warms

> > quicker as well.

>

> Let's see if Brian changes from brass to

> aluminium.

All you need to make your own is a saw, a drill and a tap. There is no lathe work necessary.

>

>

> > Covering the block with some insulation makes a

> > big difference. Not only does it use less

> power,

> > but less heat rises up to the insulator so it

> runs

> > cooler. With an uninsulated block and a heated

> bed

> > ,the top of the insulator gets too hot for PLA.

>

> Hmm, I did that in past. I still believe that a

> cooler PTFE/PEEK is important. Would be great if

> brass get cold in the end!

Don't understand, the brass is the hot part?

>

> However I still like the idea of PTFE inside brass

> barrel, I would like to buy such brass barrel. Did

> you tested one already?

No I haven't tried that but it should work. I don't like PTFE unless it is totally constrained as it is in my Plumbstruder and Brian's hybrid. I run my Plumstruder at 255C for the first layer and it is 100% reliable. It is quite heavy though.

[www.hydraraptor.blogspot.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 16, 2010 11:01AM |

Registered: 14 years ago Posts: 356 |

> All you need to make your own is a saw, a drill

> and a tap. There is no lathe work necessary.

Thanks for the idea/info. I have all of that, less the tap. I have to buy the aluminium + tap. Yeah, I don't have a lathe, sure :-)

> > Hmm, I did that in past. I still believe that a

> > cooler PTFE/PEEK is important. Would be great

> if

> > brass get cold in the end!

>

> Don't understand, the brass is the hot part?

I mean, the brass barrel gets hot with heater, at the other end, it could get cold so we wouldn't need any PTFE! Right?

After reading your blog message [hydraraptor.blogspot.com] , I do understand that is really important to get the PTFE/PEEK as cold as possible. I will try using your ideas, like insulating the heater and do the reverse on PTFE/PEEK.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

> and a tap. There is no lathe work necessary.

Thanks for the idea/info. I have all of that, less the tap. I have to buy the aluminium + tap. Yeah, I don't have a lathe, sure :-)

> > Hmm, I did that in past. I still believe that a

> > cooler PTFE/PEEK is important. Would be great

> if

> > brass get cold in the end!

>

> Don't understand, the brass is the hot part?

I mean, the brass barrel gets hot with heater, at the other end, it could get cold so we wouldn't need any PTFE! Right?

After reading your blog message [hydraraptor.blogspot.com] , I do understand that is really important to get the PTFE/PEEK as cold as possible. I will try using your ideas, like insulating the heater and do the reverse on PTFE/PEEK.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 16, 2010 12:05PM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

I mean, the brass barrel gets hot with heater, at the other end, it could get cold so we wouldn't need any PTFE! Right?

Brass is an order of magnitude better thermal conductor than stainless steel so you waste a lot of heat that way and need a big heatsink. To do a PTFE less version you should use stainless steel.

For my next extruder I am going to try something like this [www.thingiverse.com], but without the big washer and the bolts. Just a stainless steel bolt drilled down the middle and with a grove to make a thermal break and some penny washers between brass nuts to make vanes and a tiny fan with a reprapped duct.

[www.hydraraptor.blogspot.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 21, 2010 06:11PM |

Registered: 14 years ago Posts: 8 |

Hi Brian,

Were you thinking about making some aluminum power resistor heater blocks for use with your extruder nozzles like Nopheads design?

[hydraraptor.blogspot.com]

Were you thinking about making some aluminum power resistor heater blocks for use with your extruder nozzles like Nopheads design?

[hydraraptor.blogspot.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 21, 2010 06:29PM |

Admin Registered: 17 years ago Posts: 7,879 |

That one is easy to make with just a drill press and some taps. If you are going to make use of a machinist this one works a lot better [hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 21, 2010 10:16PM |

Registered: 14 years ago Posts: 8 |

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 22, 2010 11:34AM |

Registered: 15 years ago Posts: 537 |

MacGeiger Wrote:

-------------------------------------------------------

> Hi Brian,

>

> Were you thinking about making some aluminum power

> resistor heater blocks for use with your extruder

> nozzles like Nopheads design?

> [hydraraptor.blogspot.com]

> r-quick-heater-hack.html

Hello,

At the present, I haven't had any plans to make a heater block, similar to Nopheads design. I have made some brass heater blocks, with a heater resistor installed, but they are very experimental and I don't advertise them. The heater block, that I have made, is basically a block of brass with an M6x1 tapped hole, for the heater barrel, and another hole, for the heater resistor.

Regards,

Brian

-------------------------------------------------------

> Hi Brian,

>

> Were you thinking about making some aluminum power

> resistor heater blocks for use with your extruder

> nozzles like Nopheads design?

> [hydraraptor.blogspot.com]

> r-quick-heater-hack.html

Hello,

At the present, I haven't had any plans to make a heater block, similar to Nopheads design. I have made some brass heater blocks, with a heater resistor installed, but they are very experimental and I don't advertise them. The heater block, that I have made, is basically a block of brass with an M6x1 tapped hole, for the heater barrel, and another hole, for the heater resistor.

Regards,

Brian

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 25, 2010 06:07PM |

Registered: 14 years ago Posts: 356 |

reifsnyderb Wrote:

-------------------------------------------------------

> At the present, I haven't had any plans to make a

> heater block, similar to Nopheads design. I have

> made some brass heater blocks, with a heater

> resistor installed, but they are very experimental

> and I don't advertise them. The heater block,

> that I have made, is basically a block of brass

> with an M6x1 tapped hole, for the heater barrel,

> and another hole, for the heater resistor.

Your brass heater block works very well. I think everyone should forget nichrome wire!!. Please start providing/selling the resistor heater block, it is a big/expressive advance on extruder technology!! (thanks NopHead)

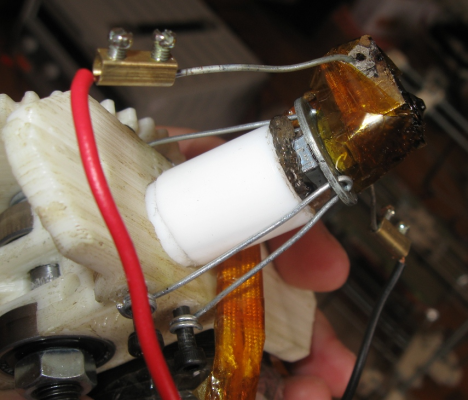

I printed a few parts in a few different days, using your extruder parts, including the brass resistor heater block you sold to me a some days ago. I am using the "long" brass barrel + 0.35mm nozzle + brass power resistor block + PTFE drilled and taped by me.

I tried to follow the advices from NopHead and others, and so I tried to insulate the heater area with Kapton tape (maybe just a very small insulation). Also I used a file to make the nozzle a bit more smaller (maybe 5% smaller). Since the brass barrel is relative long, I hope it get a bit cool when arrives to PTFE.

On PTFE I used this 2 hose clamps, to help get it cooler as possible and to strength it against extruder forces.

And one IMPORTANT thing were to flat and drill the brass barrel, to try make the PTFE stay inside it!!! just like the new nozzles :-)

That brass barrel from picture were a first try - I didn't take pictures from the one is printing now. I tried to make it flat first and then drill it a few mm so just stay a very thin wall (more than that from picture) and including the original thread. Then I screwed the brass barrel on PTFE as usual, but in the end it screwed much more and so PTFE went inside brass barrel. I had then to drill the PTFE because it expanded inside brass barrel.

Well, it may be just a little of PTFE inside brass barrel, but my extruder is perfectly working now while it was not before!!! Before it were jamming and leaking :-( -- but for now I just printed using PLA. ABS is what I want and since it needs higher temperature, this extruder may not works as it works for PLA. I didn't tested/printed yet with ABS because my current Heated Bed just goes up to 70ºC what is not enough for printing with ABS.

Edited 6 time(s). Last edit at 09/25/2010 06:28PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> At the present, I haven't had any plans to make a

> heater block, similar to Nopheads design. I have

> made some brass heater blocks, with a heater

> resistor installed, but they are very experimental

> and I don't advertise them. The heater block,

> that I have made, is basically a block of brass

> with an M6x1 tapped hole, for the heater barrel,

> and another hole, for the heater resistor.

Your brass heater block works very well. I think everyone should forget nichrome wire!!. Please start providing/selling the resistor heater block, it is a big/expressive advance on extruder technology!! (thanks NopHead)

I printed a few parts in a few different days, using your extruder parts, including the brass resistor heater block you sold to me a some days ago. I am using the "long" brass barrel + 0.35mm nozzle + brass power resistor block + PTFE drilled and taped by me.

I tried to follow the advices from NopHead and others, and so I tried to insulate the heater area with Kapton tape (maybe just a very small insulation). Also I used a file to make the nozzle a bit more smaller (maybe 5% smaller). Since the brass barrel is relative long, I hope it get a bit cool when arrives to PTFE.

On PTFE I used this 2 hose clamps, to help get it cooler as possible and to strength it against extruder forces.

And one IMPORTANT thing were to flat and drill the brass barrel, to try make the PTFE stay inside it!!! just like the new nozzles :-)

That brass barrel from picture were a first try - I didn't take pictures from the one is printing now. I tried to make it flat first and then drill it a few mm so just stay a very thin wall (more than that from picture) and including the original thread. Then I screwed the brass barrel on PTFE as usual, but in the end it screwed much more and so PTFE went inside brass barrel. I had then to drill the PTFE because it expanded inside brass barrel.

Well, it may be just a little of PTFE inside brass barrel, but my extruder is perfectly working now while it was not before!!! Before it were jamming and leaking :-( -- but for now I just printed using PLA. ABS is what I want and since it needs higher temperature, this extruder may not works as it works for PLA. I didn't tested/printed yet with ABS because my current Heated Bed just goes up to 70ºC what is not enough for printing with ABS.

Edited 6 time(s). Last edit at 09/25/2010 06:28PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 27, 2010 07:48PM |

Registered: 15 years ago Posts: 537 |

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 28, 2010 04:46AM |

Admin Registered: 17 years ago Posts: 7,879 |

I have just made a new heater block for my Mendel from aluminium, similar dimensions to the one I use on HydraRaptor. It uses a smaller resistor, which allows it to have a smaller surface area. It is only16mm x 12mm x 8mm. That makes it use less power and heat up much quicker. I will blog a drawing later today.

I would definitely recommend aluminium over brass. It heats quicker, conducts better, is lighter and cheaper. Slightly more difficult to machine, but I did it easily with just a drill press, an M6 tap and a little paraffin.

[www.hydraraptor.blogspot.com]

I would definitely recommend aluminium over brass. It heats quicker, conducts better, is lighter and cheaper. Slightly more difficult to machine, but I did it easily with just a drill press, an M6 tap and a little paraffin.

[www.hydraraptor.blogspot.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 28, 2010 07:04AM |

Registered: 14 years ago Posts: 356 |

I also think that heater brass barrel N-RR2 is the best, because is longer and so PTFE can get cooler, also Mendel X carriage is longer and so barrel need to be longer!

But I THINK THAT N-RR2 is wrong on the face that screws on PTFE! That face needs to have thread and not like as actual, were hot/melted plastic can go between PTFE and brass barrel, ended up like on this picture:

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

But I THINK THAT N-RR2 is wrong on the face that screws on PTFE! That face needs to have thread and not like as actual, were hot/melted plastic can go between PTFE and brass barrel, ended up like on this picture:

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) September 28, 2010 07:56AM |

Admin Registered: 17 years ago Posts: 7,879 |

You don't want the top of the brass to be much cooler as it will make the molten plastic harder to push. I keep the brass part as short as possible. Less ooze and less flow resistance. Also you don't want the nozzle much below the carriage as it reduces the height of what you can build. The PTFE needs to be completely enclosed to make it reliable. With my plumbstruder I have run it at over 260C and it never leaks and it can't elongate either, which makes Z calibration much easier.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) November 13, 2010 04:27PM |

Registered: 14 years ago Posts: 71 |

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) November 16, 2010 12:16PM |

Registered: 15 years ago Posts: 537 |

spaztik Wrote:

-------------------------------------------------------

> I will likely be buying a combination heater

> barrel/nozzle and thermal barrier from you in the

> near future. I am wondering if you have considered

> manufacturing the hobbed bolt for Wade's extruder.

> If you offered this part I would buy one and I

> suspect it would be another good seller.

Hello,

Sorry about the late reply. I have considered making the hobbed bolt; but, I have not had any luck making the hobbing. I spent some time experimenting, over the summer, and have not had time to try lately. My guess is that my configuration has too much friction. I haven't taken the time to machine another fixture to hold the bolt. I should probably try a fixture that has bearings in it.

Regards,

Brian

-------------------------------------------------------

> I will likely be buying a combination heater

> barrel/nozzle and thermal barrier from you in the

> near future. I am wondering if you have considered

> manufacturing the hobbed bolt for Wade's extruder.

> If you offered this part I would buy one and I

> suspect it would be another good seller.

Hello,

Sorry about the late reply. I have considered making the hobbed bolt; but, I have not had any luck making the hobbing. I spent some time experimenting, over the summer, and have not had time to try lately. My guess is that my configuration has too much friction. I haven't taken the time to machine another fixture to hold the bolt. I should probably try a fixture that has bearings in it.

Regards,

Brian

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) November 17, 2010 03:02AM |

Registered: 13 years ago Posts: 56 |

Hey Im very interested in getting bits for an extruder but Im still doing research as to what i need (up until an hour ago I didnt know anything about extruders so I'm sorry if my questions are stupid and I overlooked something simple).

Questions:

Do you sell the resistor block variation for the heater?

If I get the peek sleeve listed on your first post, can i just attach the hot end directly to the cold end and neglect the peek or metal brace [example] that presses the brass nozzle up with those long screws and washers.

If not, what solutions do you suggest?

What purpose does a nozzle serve as opposed to a heater barrel with the desired diameter orifice?

If I do need a separate nozzle, does it work with the resistor heater block?

I would like to get as many hot end bits from you as possible. I find your prices to be extremely reasonable and you are located relatively near me so shipping shouldn't take long. (I live in NYC).

Questions:

Do you sell the resistor block variation for the heater?

If I get the peek sleeve listed on your first post, can i just attach the hot end directly to the cold end and neglect the peek or metal brace [example] that presses the brass nozzle up with those long screws and washers.

If not, what solutions do you suggest?

What purpose does a nozzle serve as opposed to a heater barrel with the desired diameter orifice?

If I do need a separate nozzle, does it work with the resistor heater block?

I would like to get as many hot end bits from you as possible. I find your prices to be extremely reasonable and you are located relatively near me so shipping shouldn't take long. (I live in NYC).

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) November 18, 2010 09:24AM |

Registered: 15 years ago Posts: 537 |

Hello,

Waiasaur Wrote:

-------------------------------------------------------

> Hey Im very interested in getting bits for an

> extruder but Im still doing research as to what i

> need (up until an hour ago I didnt know anything

> about extruders so I'm sorry if my questions are

> stupid and I overlooked something simple).

>

> Questions:

>

> Do you sell the resistor block variation for the

> heater?

Yes, I do have one. It is $10.00 and includes the resistor. There is also a hole drilled for the mounting of the thermistor.

> If I get the peek sleeve listed on your first

> post, can i just attach the hot end directly to

> the cold end and neglect the peek or metal brace

> that presses the brass nozzle up with those long

> screws and washers.

Are you referring to the "Geared Extruder Nozzle" variation? (http://reprap.org/wiki/Geared_extruder_nozzle) I have been selling the hole kit, minus the rods and thermistor, for $45.00 each, on E-Bay from time to time.

You can just get a PEEK (or PTFE or hybrid) thermal barrier and a combination nozzle. While many people have had success with the PTFE thermal barrier, the hybrid thermal barrier really gives you the best of both worlds.

> If not, what solutions do you suggest?

At minimum, I would use a hybrid thermal barrier and a combination nozzle.

> What purpose does a nozzle serve as opposed to a

> heater barrel with the desired diameter orifice?

The separate nozzle allows you to have a selection of nozzles, with different sizes, in order to produce a different resolution of extrusion.

> If I do need a separate nozzle, does it work with

> the resistor heater block?

Yes, the separate nozzles and heater barrels will work with the resistor heater block.

> I would like to get as many hot end bits from you

> as possible. I find your prices to be extremely

> reasonable and you are located relatively near me

> so shipping shouldn't take long. (I live in NYC).

Thank you. Please contact me directly at reifsnyderb (a_t) hotmail (d_o_t) com

Regards,

Brian

Waiasaur Wrote:

-------------------------------------------------------

> Hey Im very interested in getting bits for an

> extruder but Im still doing research as to what i

> need (up until an hour ago I didnt know anything

> about extruders so I'm sorry if my questions are

> stupid and I overlooked something simple).

>

> Questions:

>

> Do you sell the resistor block variation for the

> heater?

Yes, I do have one. It is $10.00 and includes the resistor. There is also a hole drilled for the mounting of the thermistor.

> If I get the peek sleeve listed on your first

> post, can i just attach the hot end directly to

> the cold end and neglect the peek or metal brace

> that presses the brass nozzle up with those long

> screws and washers.

Are you referring to the "Geared Extruder Nozzle" variation? (http://reprap.org/wiki/Geared_extruder_nozzle) I have been selling the hole kit, minus the rods and thermistor, for $45.00 each, on E-Bay from time to time.

You can just get a PEEK (or PTFE or hybrid) thermal barrier and a combination nozzle. While many people have had success with the PTFE thermal barrier, the hybrid thermal barrier really gives you the best of both worlds.

> If not, what solutions do you suggest?

At minimum, I would use a hybrid thermal barrier and a combination nozzle.

> What purpose does a nozzle serve as opposed to a

> heater barrel with the desired diameter orifice?

The separate nozzle allows you to have a selection of nozzles, with different sizes, in order to produce a different resolution of extrusion.

> If I do need a separate nozzle, does it work with

> the resistor heater block?

Yes, the separate nozzles and heater barrels will work with the resistor heater block.

> I would like to get as many hot end bits from you

> as possible. I find your prices to be extremely

> reasonable and you are located relatively near me

> so shipping shouldn't take long. (I live in NYC).

Thank you. Please contact me directly at reifsnyderb (a_t) hotmail (d_o_t) com

Regards,

Brian

|

Re: Lowest Prices on Machined Extruder Parts -- Heater Barrels, Nozzles, Thermal Barriers (PTFE, PEEK, Hybrid) November 23, 2010 12:14AM |

Registered: 13 years ago Posts: 56 |

Sorry, only registered users may post in this forum.