BasicMendel

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: experimental

| Description | A basic simple 3D printer based on Mendel to print all the parts needed to build Huxley or Mendel uses only materials & components that anyone can make or buy. Low cost low tech.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Introduction

For the last two years I have been building various RepStrap versions of Darwin and Mendel trying to devise simple ways to build these printed self replicating machines. BasicMendel is based on my RepstrapMendel. This was my first working Repstrap Design. This is the final Design most of it I have alredy bloged.

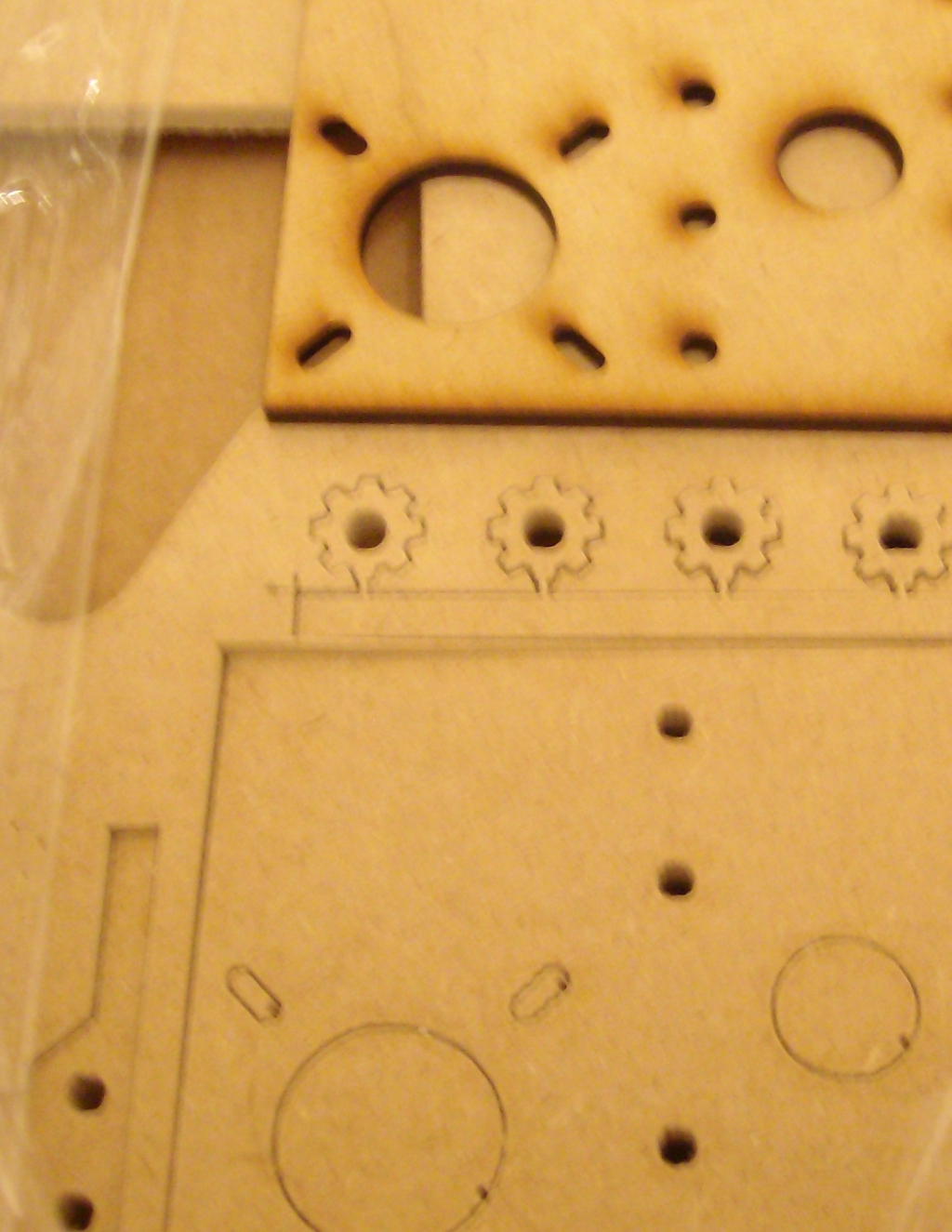

Here are the latest drawings used to build Basic Mendel please note Huxley Seedling when completed is the easier machine to build.

Done

Re designe some parts for easier assembly and to alow any thickness of material to be used.

Made in diffrent materials of diffrent thickness - failed to line up in two places i dont want elongared holes so a small redesign req.

Belt Splitter tested in both forms lasercut and hardboard hand made version. Works with both methods of making.

Then re-making every part from those drawings might try other means to make from drawings.. Taking a trip into Manchester to FAB LAB MCR was very interesting and shaved at least a week off of drawing testing time.

Estimated total cost below £300 in parts.

To do list

Add old Electronics and test Axis movement, aligment, repeatability on the experimetal version

Test the flat pack version of wades extruder.

Parts list in ods spread sheet.

Design low cost electronics.

Documenting each stage

Photographing the build process.

Listing raw materials tools etc.

Spell checking every thing.

Working Notes

I have used the Belt Splitter for the really long belts for my DIY Laser Cutter build. Low cost bearing solutions based on RepStrap Bertha builds alowing for upgrade to high quality linear bearings. We spent an interesting day at Fab Lab MCR . testing some of the drawings out using the Laser cutter. Slight modifications are required to some of the drawings.

Materials

Sheet material MDF or Ply or Perspex/Acrlic or HDPE or Aluminum.

Fix It Blocks (62)

M4 Screws Sizes/numbers to be defined not to far diffrent from the Mendel screws (not so many)

Steel bar or Stainless Steel Bar, Threded bar, Steel or plastic or Aluminum tube.

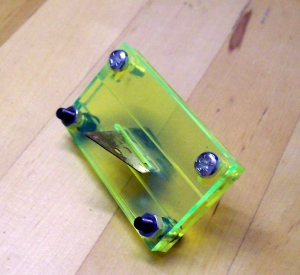

Benifits of using Fix IT Blocks:-

Reduced number of Nylock nuts or locking washers

Prevents Acrlic from cracking / breaking

Ensures a 90 degree angle.

Noise reduction.

Benifits of using Acrlic over Plywood and MDF

Improvement of acuracy due to warping of Plywood even high quality laser Plywood and MDF had slight warping (>0.5mm)

It looks far better than wood.

Disadvantage of using Acrlic over Plywood and MDF

The disadvanages in this case are:-

Cost of Acrlic is usualy more than twice the price of Plywood and 3 times the price of MDF.

Cost of laser cutting is more for Acrlic as it takes longer to laser cut than MDF and Plywood.

Benifit of Laser cutting over waterjet cutting

The tolerance of the cut is better with Laser cutting as the size of the water jet can change for combinations of these reasons.

The size of the garnet/ cutting medium can vary.

The wear on the diamond or spaphire cutting head changes as its used.

Wear on the focusing tube.

All of the above change the size of the kerf the kerf is the size of the jet typicaly 1.6mm.

The Kerf is cone shaped so cut edges have a slight taper from the top of the cut to the botom.

Another disavantage is the cut edge finish feels is a bit like fine sandpaper.

With water jet cutting parts need to have a border around them thus the cut length is longer this could explain the 20-30% diffrence in price.

(ie Water Jet cutting seems to be 20-30% more expensive than Laser cutting).

Also parts >60mm diameter need to have a tab to stop them being blown away with the waste. A tab is bit like spew on an airfix model holding the parts together.

Note

MDF and Plywood can be cut with just water this avoids most of the problems except for the need for Tabs.(water without abrasive added)

The Kerf with water only is typicaly 0.5 to 0.8mm

Advantage of water jet cutting MDF and Plywood there are no burn marks.

Yes MDF and PLYwood can be water jet cut They do not come out wet. In the pic you can see the Tabs and the kerf hole in 5 o'clock position of all the cutouts.

The Belt Splitter

- Main page: belt splitter jig.

Drawings

Belt Splitter drawings

Media:Small_140mmx70mm_beltSplitterorg.pdf

Use 3mm Perspex,MDF,PLy,hardboard

Make it at home print it to scale stick with glue stick onto 3mm MDF or hard board.

Drill out the 10 x 4mm holes using a hand drill, electric drill, dremel

Drill out the ends of the 4mm slots ie (4 x 4mm holes) using a hand drill, electric drill, dremel

Cutting MDF or hardboard with a craft knife/stanly knife is done by making repeated cuts/scores on the line don't try to do it in one cut!!

Use a stanley knife or Dremel to cut out the lines of the 2 x 4mm slots. Now you can cut the 2 blade slots they are 0.8mm wide I used a small craft knife then snapped the slither out.

Check you have all the holes drilled and the 4 slots cut out before cutting the out lines. This is done using a dremel saw, hack saw, craft saw or even using the craft knife scoring method.

Assemble it using 4mm screws.

Using the Belt Spliter Belt splitter jig

Thingyverse link http://www.thingiverse.com/thing:4952

>------------------------------------

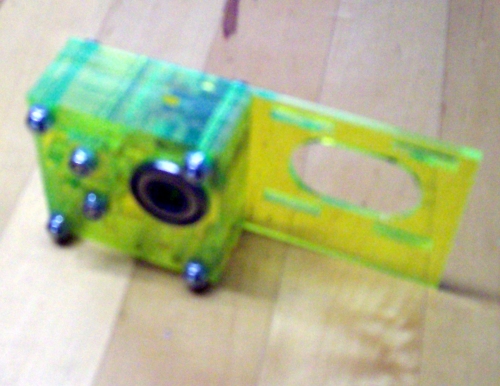

Wades Extruder

- Main page: Wade's Geared Extruder.

Drawings for Wades_Extruder

Needs up dateing >> Media:Wades_Extruder.pdf

Used 3mm Perspex,MDF,PLy

Make it at home print it to scale stick with glue stick onto 3mm MDF or hard board.

Drill out the 14 x 3mm holes using a hand drill, electric drill, dremel

Drill out the 45 x 4mm holes using a hand drill, electric drill, dremel

Drill out the ends of the 4 3mm slots ie (8 x 3mm holes) using a hand drill, electric drill, dremel

Drill out the ends of the 14 4mm slots ie (28 x 4mm holes) using a hand drill, electric drill, dremel

Drill out the ends of the 4 5mm slots ie (8 x 5mm holes) using a hand drill, electric drill, dremel

to be continued.. ~

Cutting MDF or hardboard with a craft knife/stanly knife is done by making repeated cuts/scores on the line don't try to do it in one cut!!

Use a stanley knife or Dremel to cut out the lines of the 4 x 3mm slots.

Use a stanley knife or Dremel to cut out the lines of the 14 x 4mm slots.

Use a stanley knife or Dremel to cut out the lines of the 4 x 5mm slots.

Check you have all the holes drilled and the 22 slots cut out before cutting the out lines. This is done using a dremel saw, hack saw, craft saw or even using the craft knife scoring method.

Assemble it using 4mm screws.

Worm Extruder Drive MKV Drawings go here Plus repstrap Huxley component drawings.

Basic DIY Drawings print it stick it and cut it.

Laser cutter Drawings,

The Print Bed for ABS

Electronics

For Basic Mendel any combination of the existing RepRap electronics can be used.

If you have not got any electronics Basic Mendel has its own Low cost solutions.

These are the three variations one using the Arduino Mega, Arduino UNO/Arduino Demiglove and Basic Mendels Cncduino controller.

Hardware

Steppers are NEMA 14 or NEMA 17.

Belts 80thou or 5mm pitch Syncroflex (Note 5mm pitch is easier to hand make the gears)

If I find a way to make ball chain gears at home this would be even better.

Please note this list is not final yet!!

I will post a parts spreadsheet to match that of the Mendel-m4-assembly-data-sheet.ods

File:BasicMendel-m4-assembly-data-sheet.ods

3mm Screws 20

4mm Screws xxx depending on the bearing option.

4mm Nuts xxx depending on the bearing option.

6mm Nuts xxx

8mm Nuts xxx

Threaded Bar As Mendel

Fixit blocks xxx

Fixit Block Bearings 12 or Sintered Bronze Bearings 12 or Linea ball Bearings 12

Number of unique parts xxx

Total number of parts xxx depending on the bearing option.

Tooling

Basic tools:- Printer, Glue Sticks, Electric Drill with stand, Hack saw, Sharp Chisels metric drills Hand saw craft Knife / Stanly Knife.

Advanced tools:- Pedestal Drill, Chop Saw, Dremel, router, Jigsaw, Band saw, Scroll saw any electric cutting tool.

Technophobe tools:- CNC or Laser Cutter or Water Jet Cutter or a vist to your nearest FAB LAB

Mail order:- Ponko Laser cutting service