Belt Compliance Measurement

Release status: working

| Description | Belt Compliance (stretch) Test Stand

|

| License | |

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link | []

|

Contents

Introduction

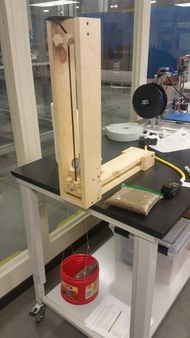

The purpose of this page is to propose a standardized, easily replicable test stand and procedure to obtain belt compliance data. Currently, real performance data for the tiny belts used in 3d printers is difficult to find and this makes engineering the system difficult. A standard test method could help the community generate data to fill this information gap and to compare belt suppliers, brands, and models quantitatively. The bill of materials, construction details, theory, and use are covered in this page.

Background

The engineering of industrial mechatronic systems requires some key pieces of data. The amount of compliance (spring-back) of the belts is one such critical piece of data. During acceleration force is applied against the belts creating position error. Position error is the difference between where the motor should have moved the load and the actual position of the load. Finding belts with the minimum compliance (stretchiness) and maximum stiffness will create a system with the best positioning accuracy and most faithful reproduction of the model being printed.

Links to other information on belts

Proposed Method

The proposed method of measuring belt compliance is to suspend a long arm from a belt and apply force by hanging weight from the arm. The movement of the arm is measured with a dial indicator. The reason for using the long arm is to keep the measuring surface located below the indicator without affecting the measurement. The tension in the belt also helps keep things centered.

Materials Required

*Dial Indicator (Currently Harbor Freight Tools No. 623) [1]

*96" (8ft) long 1x4 pin boards.

*Piece of plywood 3" x 3" to make knobs from *4 2" Drywall Screws for the clamp knobs (coarse thread flat head screws) *18 1-5/8" Drywall Screws (coarse thread flat head screws) *Two pieces of 3/4" x 3/4" x 2.5" wood blocks to make the clamp blocks