Builders/Frank

Frank is the name of the RepStrap built by Stanley Ames (Demented Chihuahua) in 2007-2008.

Build Breakdown

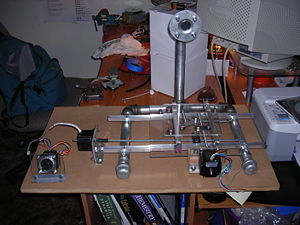

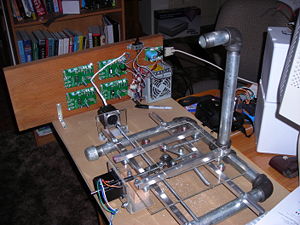

Frank was built in many stages over roughly a 10 month period which started in the summer months of 2007. He is a McWire Cartesian bot that uses the RepRap Gen 1 electronics and an Mk II extruder. Standard 200 step stepper motors from the RRRF were used and cat5e cabling was used for all the wiring. A 300 watt pc power supply runs all of the electronics and stepper motors. Limit switches, standard opto-endstops, were used for the home positions only and not for the max positions as that is really handled in the preferences page of the RepRap host software.

Frank became functional on Friday, April 18, 2008 with the printing of a minimug in fine RepRap style.

Frame

Frank's frame is a McWire design built from 1" steel water pipe and fittings. The frame is bolted to a piece of MDF for stability. None of the joints are locked in place with anything other than friction. I haven't had any problems with stability even though there was no milling on Frank. In addition, having the movable head allows me to pack Frank around to various places in order to show him off conveniently.

Mistakes

None that really come to mind. This system just works well...

Axis

The three axis of Frank use the original McWire design, except for the z-axis, which makes use of a unique piece of scavenged equipment from a universal stereo plotter. The z-axis is a slider on a piece of plate steel I call The Vertical. The slider clamps The Vertical on either side and on the front face. The slider holds itself in this position by use of magnets that hover just above the front face of The Vertical and are attached to the slider itself. This is hard to visualize so here are some pictures.

X-axis

Y-axis

Z-axis

Mistakes

- I Tried to use closet door rollers instead of 608 bearings.

- Result was not successful. Don't try the door rollers, but do try other things as this is an area that can be improved.

- Bought a piece of plexi glass for the stages.

- This is just unnecessary. Use MDF instead. It costs less, is more workable, and you won't worry about marring it because it's cheaply replaceable.

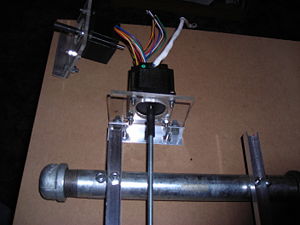

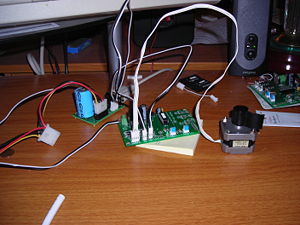

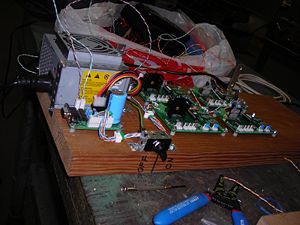

Electronics

Frank uses the following electronics:

- Pic Based Gen 1 electronics

- Universal Controller boards (4) v1.21

- Power Communication board (1) v1.3

- Opto-Endstop boards (3) v1.0.1

Mistakes

- Didn't test the electronics fully before mounting them on their board.

- Test Test Test! Why, oh, why didn't I test fully!? Stupid of me. Run through all the suggested tests before you commit to any mounting of electronics. Otherwise your electronics look like a rats nest before you ever get it running and it stays that way.

- Didn't buy extra headers and assorted connection hardware.

- Those two pin, three pin, and four pin headers and the bits that go with them are invaluable. Buy about 3 times what you will need. This allows you to make a wiring test-harness for full electronics testing and still have enough left over so that you can make a "final" electronics assembly that will look good and do you proud.

- Hard wired one of the motors, all the opto-endstops, the heater, the thermistor, and the extruder pump into the driver cards.

- This amounted to guaranteeing that I would have to desolder a bunch of junk before being able to swamp things out or run any major tests. Stupid of me. I later bought screw terminals for everything and never ran any wires directly from one device to another. There is always a way to disconnect things. In my case there are now about three ways to disconnect things which makes my life a bunch easier. Hard learned lesson.

Firmware

Frank is currently loaded with the V1.2_fullstep_all PIC firmware. I'm fairly pleased with what Frank can do with the older PIC electronics but will eventually update myself with the newer Arduino and it's associated firmware.

Mistakes

No real mistakes here. Just burn the chips and go!

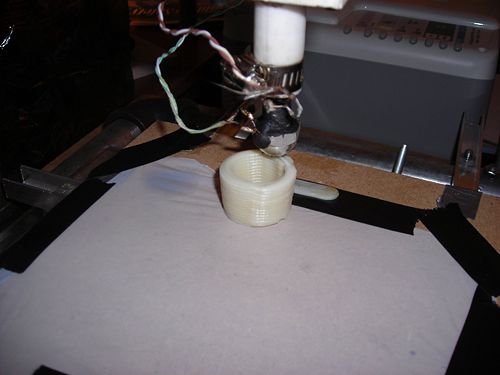

Extruder

The extruder was a huge hassle for me. Not only did I have the usual bits of trouble but I made such stupid mistakes as to give myself an entire new class of troubles! Don't repeat my mistakes.

Mistakes

- Didn't take time to find proper bolts for the extruder body.

- This caused all sorts of havoc and a range of problems occurred: the body slopping back and forth, loosening nuts, too tight a fit. Don't do this, it sucks!

- Didn't use washers.

- This was just stupid haste. I wanted to see something work and this caused a bit of trouble in getting things tight, loose, and lining up. Stupid and hasty.

- Didn't use pipe clamp on PTFE.

- About 5 minutes into my first extrusion, my heater popped out of my PTFE and started burning my y-axis print platform, and madness ensued. Avoid this if at all possible.

- Didn't drill holes through PTFE Clamp and PTFE for bolts to hold it in.

- This wasn't really my fault as this innovation hadn't been thought of yet. After I modified my assembly to include this, I had zero problem with the heater and PTFE assembly popping out of the clamp. Worked like a champ.

- Didn't insulate my heater barrel.

- This didn't cause any real problems, but it did cause me to have to twiddle my thumbs waiting for the heater to get to temp. Insulate with a piece of fiberglass insulation and wrap with some wire. This has the added benefit of keeping your heater wires and thermistor wires from moving about, possibly shorting, or breaking.

- Used Offset drive for extruder.

- Kept snapping off at the joint. Horrible design. Stay away from it. Instead, go with the direct drive model. Much better. Never had a problem with it.

- Made my own drive screw (I cut the threads myself on a lathe)

- 10-32 threads in stainless steel are a bit small to cut yourself on a lathe. Just buy 10-32 studding from McMaster or buy the whole extruder in a kit and save yourself the trouble. I'm still using my screw but would have saved hours if I hadn't.

- Didn't test the extruder before mounting it to the machine.

- Test Test Test! Clamp it to a table and run about an hours worth of extrusion through it. This allows you to work out the major kinks before you mount it and things get hairy to get to. Seriously, Test Test Test!

Errata

As yet, Frank has not reproduced...this may be because of failings in his owner--hasn't tried yet--or because Frank is sterile. Only time will tell.

In seriousness, I fully intend to make at least two copies of the Darwin parts that Frank can print. One for a friend of mine currently building a system, and another I'll make available to the world at large.

My future plans--currently being enacted--are to refurbish Frank so that he looks better than the mess you see here, and to make another Strap with a larger print volume and faster axis travel. I'm not too concerned with having a real Darwin myself as Frank can do anything a current generation Darwin can do. When the state of the art surpasses Frank's or his progeny's ability, I'll print off a Darwin and catch up.