Crispy HotEnd

Contents

A Bit of Background

This HotEnd was developed after struggling with the fact that in Argentina (were I live) PEEK is very hard to come by, very expensive and a controlled material (since it can be used to manufacture guns).

Therefore, I went and designed a PEEK-free HotEnd.

Since PTFE is available and fairly cheap, I started to work on building a HotEnd based on that insulation.

PTFE is easy to work with, threads don't last much and are quite fragile, to solve this I went on and designed a "contained" PTFE insulation.

I took some ideas from the Budaschnozzle (which I tried, unsuccessfully, to build replacing PEEK with PTFE)

I'm a Hobbyist Lathe operator, so a lot is done on my lathe. That's a lot of help and makes this cheap.

I've used this HotEnd for at least 3 months now, and around 13 Kg of filament have gone through it. Normally I print with 0.5 mm nozzles at 40 mm/sec and at 230 - 245 ºC.

I Hope some people out there find it useful.

Gustavo "Crispy" Blanco

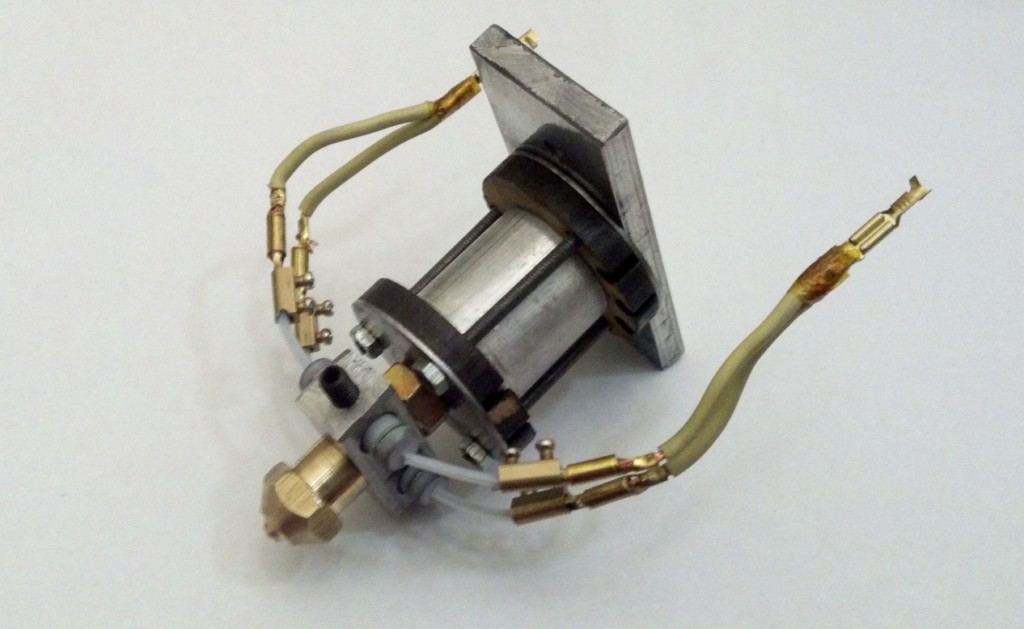

The Crispy HotEnd

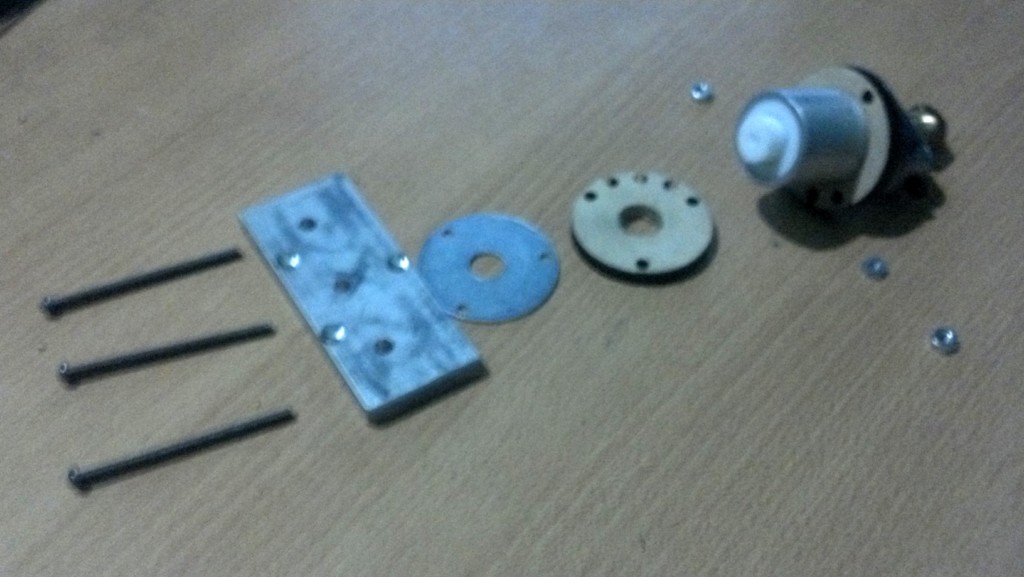

The HotEnd Disassembled

BOM (Build of Materials)

The Built

Tipically I start with the Barrel.

It's a 50mm 12mm Aluminum round bar which it turn to 8mm in diameter for 45mm, and make those 45 mm a 8x1.25 Thread.

Next, I take a piece of 1" (or 25mm) Aluminum Pipe and cut a 25mm long section.

On the Lathe and with a piece o 25mm PTFE, turn it so you can fill the pipe (try to get it tight).

With a 6.75mm Drill bit, drill the PTFE (at least 30mm deep).

Then with a 12mm Drill bit, drill 18mm into the PTFE.

Now take the 12mm PTFE and brill a 3.2 hole, drill it all the way.

Now, insert the Barrel into the large PTFE section, using the largest hole, and screw it tight.

And the small PTFE to enclose the barrel.

Complete the Mid Assembly by adding the parts in order.

To make these parts I've used the plans for the Budaschnozzle.

Check that the holes are aligned.

Now to Finish he Bottom Section, add the Heater Block and Nozzle

Notice the Heater Block has a 3mm hole drilled in the center for the thermistor.

The Top Needs to be finished as in the picture

To finish the assembly, add 2 resistors and 2 Y shaped Cables to connect the Resistors in parallel.