Cyberdyne T-1

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: unknown

| Description | Documention of the Repstrap: "The T-1"

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

"I think this would be a great place to put a quote which summarizes the design philosophy" - Johnny Cooper

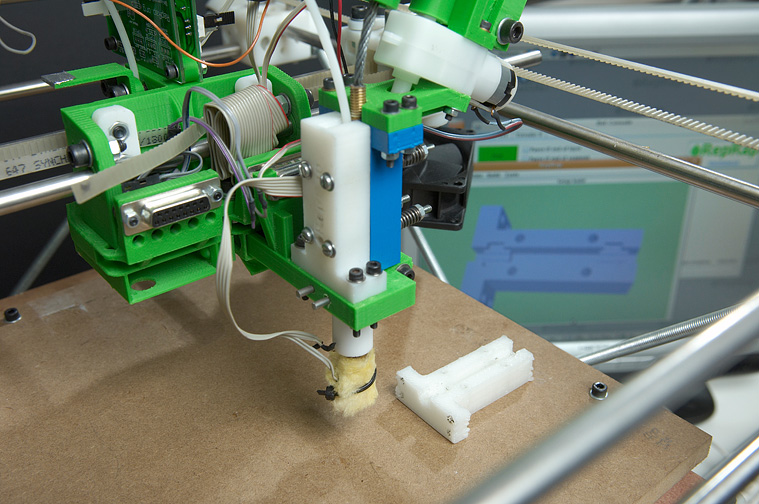

The Cyberdyne T-1 is a prototype Repstrap which has cost and simplicity as it's main driving design objectives. development page This page showcases the T-1's workings and document's it's design so that it can be reproduced by others.

Contents

Working Notes. This is a stub!

Everything below this point is working notes.

History

This is a T-1 RepStrap! I (JohnnyCooper) made it because I want to assist in the proliferation of Low Cost 3d Printers Low Cost. Share and Enjoy! (This page was made using the wiki page Example as a model.)

Supplies

-Syringes The best syringe I have been able to find is the "Becton Dickison & Co. 1ml 25G 5/8 Tuberculin SlipTip" Reorder No. 309626 available through Bi-Mart Pharmacy

-Digital Calipers Digital Calipers are generally pretty generic in terms of quality and features as far as I'm concerned however selecting one with an RS232 interface port is important as this allows for closed loop feedback to the Microcontroller. I use the Cen-Tech 6" & 12" Calipers as they are both cheap as dirt, and are more than adequate.

-Physics & Chemistry Lab Jack/Tabletop Scissor Jack Design of the Z axis isn't very interesting to me so this solution is a stop gap as much as anything, however an example of such a device is as follows:

http://www.crscientific.com/labjacks.html

This can either serve as a solution, or as an inspiration for a rapidprototype printable scissorjack/laser cut acrylic version of the same.

This design may be replaced with a homemade hydraulic bottle jack/table combination in the future.

Files and Parts

Generic/Daughter_part and CarrotStraightener. (I use a Student Edition of Solidworks for my Solid-Modeling and I'm uncomfortable with publishing the files. I will recreate them from blueprints in open source software once I have a working prototype.) Media:uploaded_files_example.zip

Photos and Drawings

http://www.mediawiki.org/wiki/Help:Images

Flicker Example

<flickr>2967868906|right</flickr>

Working Notes

Project Lead(s): JohnnyCooper can be contacted via gmail under the username "JohnnyFCooper" Wiki-maintainers and helpers:

Forum thread?

http://dev.forums.reprap.org/read.php?171,34580

Tooling

3d Printer or Drill Press & X-Y Table(http://www.micromark.com/MICROLUX-X-Y-TABLE-ATTACHMENT,8009.html)

Process

The digital calipers are intended as a replacement for lack of an X-Y table. If you already have an X-Y Table, I recommend a low budget CNC Repstrap conversion.

Fabrication of the T-1 involves the production only several parts: -Caliper Clamp 1 -> This part clamps a 6" caliper's fixed jaw to a 12" caliper's sliding jaw -Caliper Clamp 2 -> This part clamps the extrusion head to the 6" caliper's sliding jaw -Caliper Clamp 3a -> This part transforms the 12" caliper's in to a Gantry by suspending the caliper on edge on supports on either side of the Z axis Scissor Jack. -Caliper Clamp 3b -> This part accomplished the same as Caliper Clamp 3a, however it includes a stepper motor mount. Fixed jaw side? -Generic Extruder Head -> Ideally a bowden wire design, however solder paste is acceptable as well. A traditional pinch roller may be possible but I consider the weight and momentum of the pinch roll stepper to be undesirable for this design.

In the first revision: Caliper Clamp 1 & 2 contain threaded nuts(6-32?) so that a lead screw can drive them. This eliminates the need for the hydraulic control system.

Once a working 3d printer has been made, work can begin on the Cyberdyne Hydraulic Control System. This system is modeled after paste extruder toolheads using a linear actuator to drive a syringe via another syringe at a 1 to 1 ratio. The purpose of this is to separate the heavy power source and the drive mechanism so that a light weight drive mechanism can be used on the moving elements of the T-100.

Now that the design rationale has been explained, it is a downhill battle from here. I intend to have a working prototype of both the T-1 and the Hydraulic Control System by May of 2010.