Delta geometry

Contents

Presentation

A 'delta' robot or printer is a robot where a platform is maintained by three pair of arms set in a triangle. The pairs of parallel arms maintain the horizontality of the platform and the movement of these arms displace the platform in the three dimensions. Many solutions exists, but a few are used practically.

There are two principles to displace the arms pairs: 1/ Each arms pairs are installed on a main articulated arm, the movement being generated be the rotation of this main arm. The geometry is the rotational delta or 'Clavel delta' from the name of its inventor. The principle is widely used on 'pick and place' machine in a wide range of industries, from electronic to food. This system can be found in the Delta by Energetic or on the FirePick Delta printers.

2/ Arms pairs are attached to carriage sliding along parallel rails. This geometry is called 'linear delta' and is the most frequent type used in 3D printer world, the machines originating the movement being the 'Rostock' and the 'Kossel'. The term 'parallel delta' shall not be used as all robots with parallel arms are called [parallel robots].

There is another solution without rigid mechanics which is to suspend the platform to wires. There are a few examples and notably the Skydelta or this suspended delta

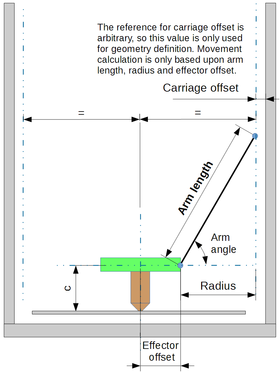

The linear delta kinematic calculation is simple because the carriage follow a straight line, so the horizontal movement of the platform is linked to the vertical movement of the carriage by Pythagorean theorem (which say that the square of the diagonal of a rectangle triangle is equal to the sum of the square of its sides). Here the diagonal is the arm length, constant, the vertical branch is the relative vertical position of the platform and carriage, the horizontal branch is the relative horizontal position of the platform and carriage. The math is not difficult, but for a printer a lot of square roots shall be done and control board based on 8 bit processors are struggling doing this calculation, so a lot of fine software optimization were done for the delta geometry for these processors.

It shall be noted that the sliders columns can be on a non-equilateral triangle and asymmetric dispositions were tested, notably the 'Square' delta with angles of 90°,90° and 180°.

Geometry of a linear delta

Schematics

The arm angle with effector at center is the result of the arms length, minimum angle and angles of the arms while at maximum diameter. For minimum angle of 20°, this angle is around 60° for maximum diameter arm verticals, but if the minimum angle is increased, it may be higher. Minimum angles of 22° will gives an angle of 63° with vertical arms.

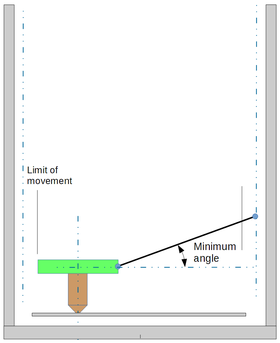

Arms may not be able to reach the vertical due to clearance problem, notably with the part cooling fans or effector accessories. In that case, for a given minimum angle, arm length may be reduced and the angle while effector is at center will be lower.

On the other way, some printers have arms capable to go over vertical (e.g. Rostock Max).

The minimum arm angle, while effector is at maximum diameter, is one of the basic design parameters. It is important for effector stability, precision and carriage speed. A low angle induce high carriage speed for a given effector horizontal speed. Low angle also decrease effector stability. Generally, 20° angle is considered as a practical minimum and induce a carriage speed 2.75 times higher than effector horizontal speed. Some printers with theoretical minimum angle of 15° may experience lost steps at their maximum diameter.

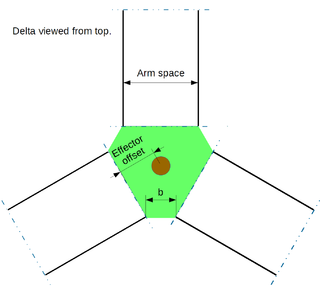

Arm space does not influence movement calculation, but have an importance for the effector stability. Best stability is obtained for the minimum offset, with the maximum possible arm space for this offset (minimising b dimension).Reachable area

For a given minimum angle, the reachable area is a triangle with bulged sides, with the ends of the triangle oriented toward the columns, which cannot be accessed without impacting the column. Then, for simplicity, the reachable area is generally considered circular. It might be interesting to evaluate the real reachable area when one want to inscribe a rectangle or square in the printing area.

Interactive web simulation

Linear deltas

- GeoGebra dSim graphic simulator for linear delta, use sliders to adjust parameters. Can be viewed in 3D with red/blue glasses.

- Thinkyhead Deltabot calculator for linear delta, enter numbers for simulation.

Rotational deltas

- Parola Java based simulator, rotational delta with many options

- http://arvc.umh.es/label/delta.html

Simulation on software

- OpenScad delta simulator for linear delta with active simulation, with common printers datasets predefined. Change variables values for simulation. You can see a film here or here (Fisher Delta)

Delta calculators

Linear deltas

- http://www.heliumfrog.com/deltarobot/details/details.html Excel sheet calculator for linear delta

- https://github.com/Jaydmdigital/mk_visual_calc OpenScad calculator with visualization dedicated to Kossel

Rotational deltas

- marginally clever Online calculator

- Trossen robotics forum

Math and research papers

- http://robinsonia.com/wp/?p=161 math explanations for linear delta

- http://scholar.rose-hulman.edu/cgi/viewcontent.cgi?article=1000&context=mechanical_engineering_grad_theses Linear delta research paper, but with the sliders parallel to the effector plan.

Rotational delta are a quite common research topic, notably for university students.

- http://www.ohio.edu/people/williar4/html/pdf/DeltaKin.pdf Rotational delta kinematics.

Calculation links

- https://hackaday.io/project/963-firepick-delta-the-open-source-microfactory/log/3588-6152014-delta-mechanism-simulation-and-accuracy-determination (Rotational delta)

Simulation without source/access

Some people have done Delta simulation on CAD/Math software, but not publicly release them.

- https://www.youtube.com/watch?v=8_6QfZ6DJfU film of a Simulation with Matlab

- https://www.youtube.com/watch?v=K2zxvHq3iC8 film

- https://www.youtube.com/watch?v=OwI6hYHWbjw A python simulator, undisclosed program.