Example DIY Supports 2

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Width of DIY Supports

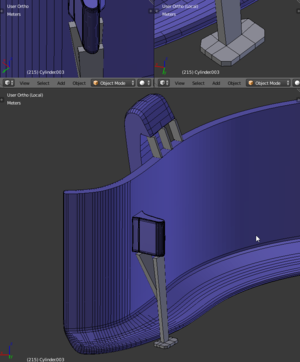

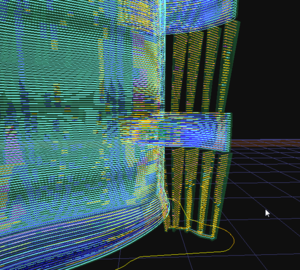

One of the complications with DIY supports is getting the widths correct. In these examples, the final print uses a .4 or .45mm extrusion width. When slicing software generates supports it is able to generate the final extrusion as single width passes; however, with these DIY supports, they appear just as any other object part does, so the slicer handles these just as it would an object. At present, most slicing software (that I've used) has limited ability to handle these "thin walls". As such, I end up going back and forth between the model and the slicing software -- in this case KISSlicer -- to ensure there aren't gaps in the supports. I often sacrifice and allow multiple passes in the support walls. The third image shows a single layer where tiny rectangular paths were created by the slicer.

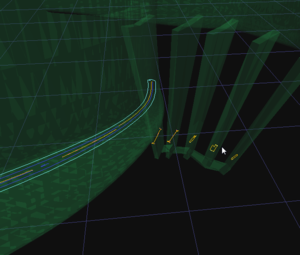

Control Over Attachment Points

It is worthwhile to note that, while these images show the control one can have over exactly where the supports attach in their modeling software, another option is Autodesk's MeshMixer, which can automatically generate objects which are efficient in material use and printing time. It is, unfortunately, presently limited (I believe, as of March 2015 or so) only to branching cylindrical tree-like structures, which it lets you output with your object, as objects, for use in your slicer of choice. The minimal nature and configurable locations of attachment is a nice feature, however, whereas most slicing software generates almost purely vertical support structures.

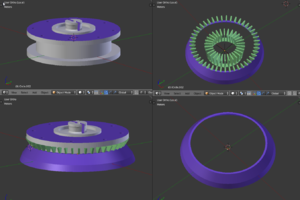

The last image is of a replacement part for an "inexpensive" air-compressor valve. The model demonstrates a ring used to build a support which spans over the bottom of the object. On top of the ring are small fins used so the extrusions run perpendicular to the paths of the overhang of the top of the spool shape. The valve is 2.70cm across, and 3.0460cm with the support-ring.