Extruder Nozzle Variations

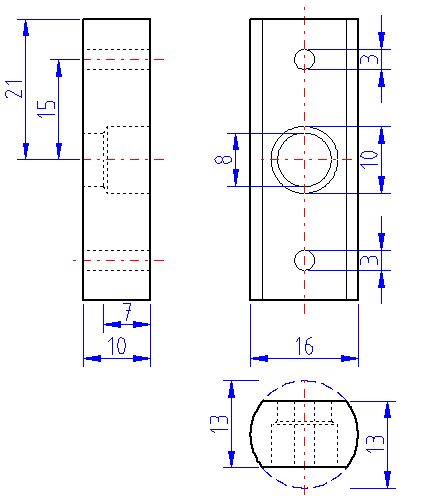

Rounded Support Block

I wanted to make a cheaper version of the support block so I decided to publish this design that uses PEEK rod instead of PEEK sheet. This is an alternative to crowd sourcing.

- Advantages

- Cheaper - more than ten times cheaper if you buy PEEK rod at £11.87 instead of PEEK sheet at £158.00

- Aesthetically pleasing - Although this is a matter of taste.

- Disadvantages

- Possibly harder to cut.

To make the rounded support block buy some 16mm dia PEEK rod. Cut a 42mm length of rod. Now cut two flats down the length of the rod. This can probably be done quite easily in a band saw, but I did it using a mitre saw using the following technique. Drill two 16mm holes into a scrap block of wood. Tap the PEEK rod into the 1st hole, the wooden block acts as a work piece clamp, now make a cut starting from the end of the rod, all the down and through the PEEK and also through the wood. Remove the peek, and put it into the 2nd hole repeating the process to get the other flat. The other holes are drilled in the same was as the original PEEK support block.

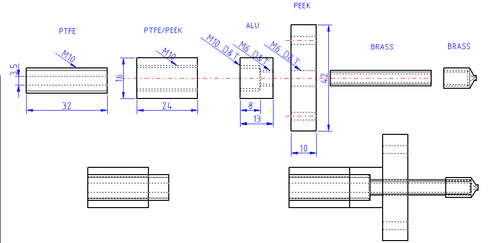

Variation 1

Giles Bathgate

After seeing Adrians Geared extruder nozzle I immediately liked it, but realized that it would be even harder to make than older designs

I offer this design as a compromise, that is similar in essence, but using nozzles and barels that can be readily bought from places like Makerbots, ReprapSource, and RepRapStores.

To make this all you really need to do is to turn down 8mm of the end of some 16mm dia ptfe to 10mm and put an external M10 thread on it. To make the middle (heatsink) part you use a piece of 16mm dia alu round bar, drill a 5mm hole all the way through the centre, then drill an 8.5mm hole to 8mm deep into one end. Tap the 5mm hole to M8 and 8.5mm hole to M10. The peek cap is almost identical to Adrians, except its 16mm in dia. I made the flange 2mm thinking that would be easier, and put M6 tapped hole instead of a 8mm clearance hole.

Missing from the drawing is the 3mm Plate (because it is identical to Adrians so unnecessary work to duplicate)