Extruder Nozzle Variations

Release status: unknown

| Description | documenting a generic tool/artpiece

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

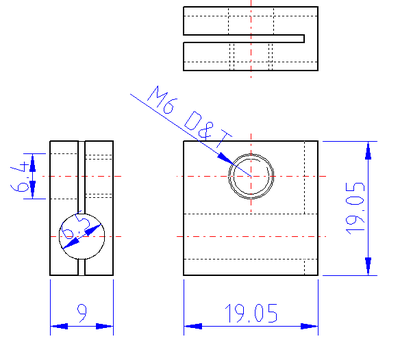

Split Heater Block

- Advantages

- No need for glue

- Looks like some kind of woodblock instrument

- Disadvantages

- Less material to conduct heat

- Looks like some kind of woodblock instrument

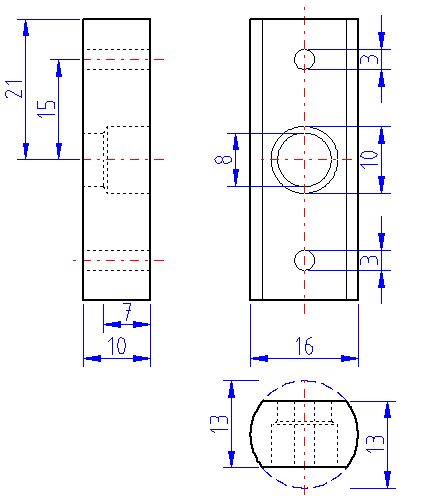

Rounded Support Block

I wanted to make a cheaper version of the support block so I decided to publish this design that uses PEEK rod instead of PEEK sheet. This is an alternative to crowd sourcing.

- Advantages

- Cheaper - more than ten times cheaper if you buy PEEK rod at £11.87 instead of PEEK sheet at £158.00

- Aesthetically pleasing - Although this is a matter of taste.

- Disadvantages

- Possibly harder to cut.

To make the rounded support block buy some 16mm dia PEEK rod. Cut a 42mm length of rod. Now cut two flats down the length of the rod. This can probably be done quite easily in a band saw, but I did it using a mitre saw and the following technique. Drill a 16mm hole into a scrap block of wood. Tap the PEEK rod into the hole in the wooden. The wooden block acts as a destructible work piece clamp, now make a cut starting from the end of the rod, all the down and through the PEEK and also through the wood. Then repeat the process to get the other flat. The other holes are drilled in the same was as the original PEEK support block.

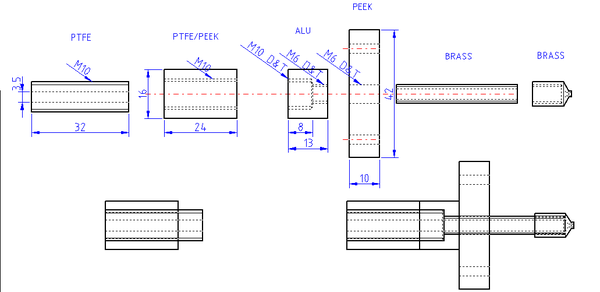

No Lathe - Variation

After seeing Adrian's Geared extruder nozzle I immediately liked it, but realized that it would be even harder to make than older designs. Reprap is supposed to be make-able in your garage, I don't even have a garage. So I offer this design as a compromise, that you can literally make in your front living room. Its similar in essence to Adrian's design. I admit its not completely lathe free since you still have to buy a nozzle. These however can be readily bought from from your fellow developers in places like the RepRap Marketplace, Makerbots, RepRapSource, and RepRapStores.

- Advantages

- Easier to make if you don't have access to a lathe.

- Disadvantages

- Still relies on some bought machined parts.

- PTFE buts up to barrel instead of being inside it.

To make this you will need to buy some 10mm PTFE and put a thread on it. Next you drill and tap some 16mm dia PTFE with an M10 internal thread. Screw the 10mm PTFE into the 16mm PTFE and you will have the completed PTFE insulator part shown bottom left. To make the middle part you use a piece of 16mm dia alu round bar, drill a 5mm hole all the way through the centre, then drill an 8.5mm hole to 8mm deep into one end. Tap the 5mm hole to M8 and 8.5mm hole to M10. Use the instructions for a rounded peek support block above to make the support block. The central hole in the block can be M6 threaded as shown if you prefer. The completed assembly is shown bottom right.