Fusionreprap

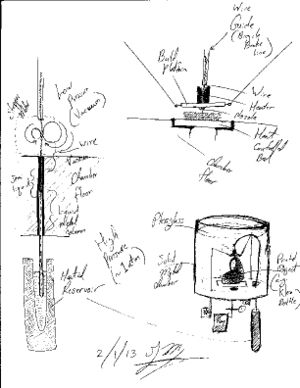

The proposed Fusion Reprap uses common metals to fabricate various objects. The printer relies on fusion welds (also called forge welds) to deposit layers of metal atop one another. To facilitate this welding process, the printed object is fabricated inside a vacuum.

The vacuum is achievable with an amateur set-up. A high vacuum is not necessary for this process. Currently, the theory is that good parts should be able to be produced in a chamber at equal to or less than 30 Torr. The necessity is for nitrogen, water, and oxygen to be sufficiently rare in the environment of the chamber. Removing oxidation from the metal is also necessary for high quality welding. Melting the metal prior to welding would remove (or at least mobilize) oxidation.

Aluminum is the test metal. Other materials could become feasible in time.

The set-up is fairly simple:

- Create an amateur-quality vacuum chamber (complete with pump, gauge, and tubing).

- Place a Rostock robot inside

- Provide a heater for the extruder.

- Provide a wire feed system for the extruder.

- Use typical reprap electronics and software (like the Sanguinololu).

Currently, a bubbler is under consideration for providing metal to the wire feed system. If that fails, simple 19 gauge wire could be used.

--SJ Moquin.