Gunstrap

Release status: Experimental

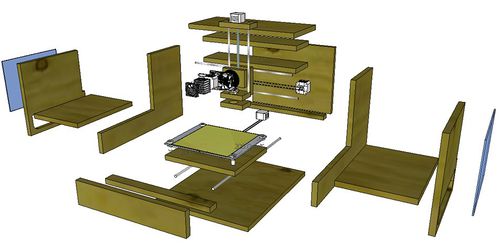

| Description | A fully enclosed heated repstrap.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

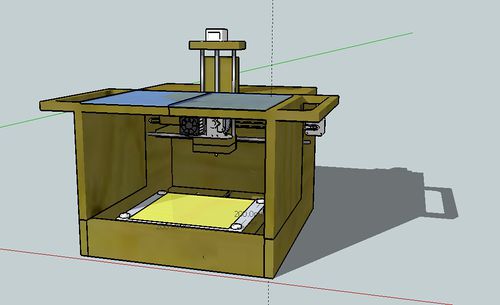

The Gunstrap is a plywood based repstrap that is constructible with only basic tools, features a heated build chamber and bed and only requires parts that can be sourced from old domestic printers and scanners.

Contents

Introduction

The Gunstrap is a plywood repstrap that is based on the Mantis CNC design. It has a build area of 200x200x100mm (comparable to the Mendel) and is employs a heated build platform and a heated build chamber capable of 70C degrees. Unlike other wood based repstrap's, no ball bearings are required for its construction, excluding the extruder and all parts can be obtained from scrapped printers and scanners.

Advantages and disadvantages

Advantages

- Has a very low build cost (around $25USD) excluding the electronics.

- Does not require any bearings apart from the extruder.

- Can be constructed with only a hack saw, drill, screwdriver and epoxy resin adhesive.

- Has a larger build area as compared to the Mantis 9.1

- Due to its fold open construction it is easy to access for cleaning and changing tool heads.

- Uses a heated build chamber which has been seen to improve the quality of prints for large objects.

Disadvantages

- Requires active thermal management in order to keep the extruder stepper motor at a safe operating temperature as its located in the heated build chamber.

- Due to the use of stainless steel sleeves instead of ball bearings, this design will ware slightly with time.

- Due to the design of the zaxis the gunstrap may not be able to achieve the same resolution as a Mendel.

- This design requires more parts to be fabricated than the original [[Mantis 9.1] in order to accommodated the heated build chamber.

- Requires the procurement of stainless steel shafts, stepper motors, belts, ect from old printers and scanners.

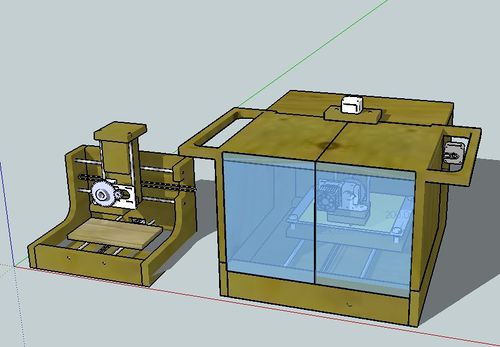

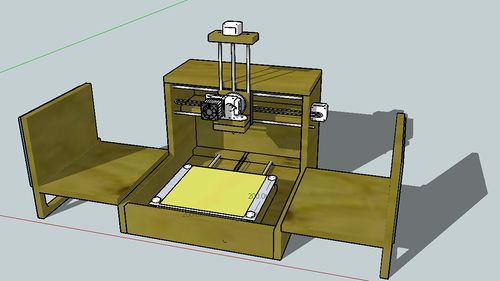

Fold Open Design

In order to accommodated access to the build platform the Gunstrap has been designed to fold open in two stages. The glass or perspex window folds up to expose the build chamber for access during a print or to make quick modifications.

For greater access the sides (with glass doors still in the folded up position) also fold down.

Build process

The design is based around using 16mm thick plywood.

Changes that could be implemented

An alternative method for keeping the extruder stepper motor cool is to use a Bowden Extruder. Examples include Ed's and Erik's| design.