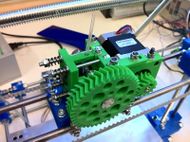

Herringbone Extruder Driver

Release status: Experimental

| Description | Geared Nema 17 Extruder

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

This is an attempt to combine various aspects of Adrian's and Wade's extruder drivers. Specifically, It keeps Adrians extruder clamping system, uses a prime number of teeth for good wear characteristics but uses Wade's hobbed bolt to do the driving.

In addition, I've also jumped on the trend to have herringbone gears to reduce backlash and for quiet running (Although your 3D printer will need to be running well to print them I suspect). Further, the hole for the grub screw of the captive nut on the small gear is at the root of one of the teeth in this design. I've printed it fine on our Stratasys, but I haven’t had the chance to RepRap it yet and suspect that the way I've done the grub hole might be a little intricate. The gears have the same pitch as Adrian's, so they should print fine anyway. I'd appreciate feed back or better yet if someone wants to improve it feel free.... Instructions

Manufacture of the bolt is the same as Wades, but you'll need an M8x70 instead. Also, on my pictures you'll notice the layout of the bolt goes - Gear, 2X Washers, Spacer, Washer, Bearing, Washer, Gap, Washer, Bearing, Washer, 2X m8 Nuts.

You should really put 3 washers at the beginning instead of 2, (I screwed up the hobbing of the bolt). Equally, the final two nuts do not need to be done up tightly, doing so would mean the bearings become a little rough. The herringbone gears should keep everything aligned by themselves and the bolt takes all the torque, so the nuts only need to be lightly tightened...