Hydra-MMM Software and Firmware

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: unknown

[[image:[image: Hydra-MMM_logo.jpg]|center|190px]]

| Description | Java host software with Arduino firmware

|

| License | |

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Project Background

'Hydra is a multi-headed manufacturing machine that is originally being designed and built for ME463 (senior design) at Purdue University. The general idea is to make a personal manufacturing machine that will be able to perform multiple, simultaneous operations such as milling, additive prototyping, pcb fabrication, laser etching, etc. For the most part, current industrial workplaces have dedicated machines for each one of these functions. By having multiple independent toolheads on the machine, Hydra will be able to perform compound operations that are not possible on dedicated machines (ie FDM rapid prototyping and milling for more accurate part outlines). Hopefully the project will lead to potential discoveries of new manufacturing techniques through the use of compound operations, as well as create a very cost effective product for small business or educational institutions who cannot afford current commercial machines.

The Sourceforge project will contain the microcontroller firmware and host software for the machine. The firmware was written in the Arduino development environment (http://www.arduino.cc/) and is currently being used on an Arduino Mega microcontroller. The software is written in the Processing development environment (http://processing.org/) and is written in Java. Because of this the host software can be run on Windows, Mac OS, and Linux operating systems. The software and firmware communicate via a serial interface. Standard machine language (Gcode) as well as custom M codes are being used for communication.

Please see: http://cpwebste.blogspot.com/ for more information about the build or https://sourceforge.net/projects/hydra-mmm/ for all future releases'

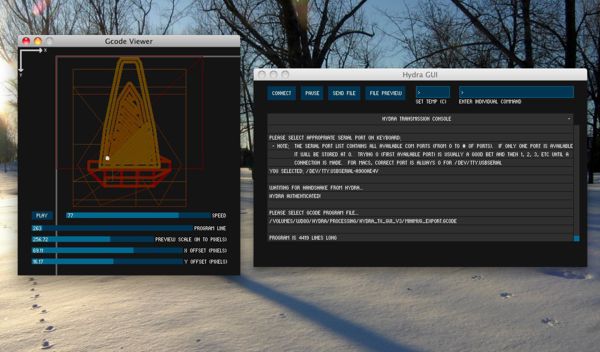

A screenshot of the GUI is below:

Installation

Firmware: After downloading the latest release please copy the Arduino libraries (cpwStepper and PID_Beta6) to the Arduino Sketch Folder/libraries/. The Arduino sketch folder can be changed from the Arduino preferences menu. If the libraries folder does not current exist, please create it and copy the files there. Next, use the Arduino software to upload the Arduino .pde sketch to a compatible microcontroller.

Software: The host software can be run from the /Processing/*release*/application.your_operating_system folder. The Processing .de sketch can also be placing in the Processing application and compiled and run from there. A USB serial connection must be established between your computer and the microcontroller before running the software. Please see the Arduino and Processing websites and forums if you have any trouble with USB serial drivers. Once the software starts, click the "Connect" button to get going and follow the onscreen prompts.

Gcode File Preview: The file preview function can be used without connecting an Arduino to the serial interface. Just run the processing program and you press the "File Preview" button to preview a gcode file.

Communication Protocol

Standard machine language (gcodes) were used to communicate to the machine. A listing of the currently available G and M codes are below.

Gcode References

G0 - rapid positioning, input X Y Z, syntax: G0 X1.25 Y0.025 Z0.0

G1 - linear interpolation, input X Y Z F(feedrate in inch/min or mm/min depending on unit sys), syntax: G1 X1.5 Y0.5 Z0.0 F10.0

G4 - dwell, input P(dwell time in seconds), syntax: G4 P3.0

G20 - inch unit system

G21 - millimeter unit system

G30 - set reference point 1

G31 - return to reference point 1

G32 - set reference point 2

G33 - return to reference point 2

G90 - absolute coordinate system

G91 - incremental coordinate system

G92 - set current position as absolute zero/home

Mcode Reference

M2 - stop program

M3 - spindle on, CW

M4 - spindle on, CCW

M5 - spindle off

M46 - enable software endstops

M47 - disable software endstops

M48 - max speed override, input F(new max feedrate), syntax: M48 F100.0

M49 - disable speed override

M50 - change step mode, input X Y Z, syntax: M50 X1 Y1 Z4 (set x and y axes to full torque and use 4x microstepping on z)

M104 - set extruder temperature, input S, syntax: M104 S200 (set target temp to 200 deg C)

M106 - turn fan on

M107 - turn fan off

M201 - turn light on

M202 - turn light off

Credits

Credits to Purdue University for supporting and inspiring the original machine. Original design team consisted of 6 members who may or may not want their names released to the public.

Credits to the Reprap project for much of the inspiration for the original machine as well as the software/firmware interface.

Credits to the Arduino and Processing development environments for making a great piece of software that is very versatile and easy to use.

Credits to the very easy to use controlP5 library written by Andreas Schlegel (http://www.sojamo.de/libraries/controlP5/)

Credits to Brett Beauregard for the PID Library for the Arduino Playground that is used for temperature control (http://www.arduino.cc/playground/Code/PIDLibrary)

Updates

v1.0

- First release on sourceforge!

- GUI now includes ability to preview gcode files as well as a realtime viewer for showing what commands are currently being sent to the machine

- Ability to send and control temperature via PID control has been added

- Custom microstepping library was written to allow for simplified control of stepper motors

- Stepping mode can be changed on the fly (includes wave drive, full torque, half stepping, and microstepping from 4x-64x)