J Head Nozzle

Release status: working

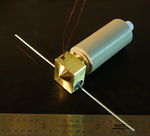

| Description | J-Head Nozzle and Thermal Barrier Based on a combination of ideas from the Makerbot Mk 5 hot end, The Inline Heater Variation, some ideas from Brian Briggs, and some ideas from me.

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Introduction

NOTE: All Research and Development on J-Head Hot-ends has stopped due to the availability of cheap chinese counterfeits that have been spammed throughout the online markets, don't work well, and have no support.

This nozzle is a combination of ideas from other nozzle designs combined with a goal to reduce the number of custom machined parts to a bare minimum. By reducing the number of machined parts, it is hoped that the cost of this hot-end can be kept down while improving the reliability.

The use of a machined piece of round PTFE, as a liner, was requested in one of two designs by Brian Briggs.

The idea of using the PTFE tubing as a liner, from the Cold End to the tip, was borrowed from the Makerbot Mk V extruder design.

The PTFE tubing also acts to "bridge" the joint between the PEEK insulator and the brass nozzle/heater. By not having the filament in contact with this joint it is hoped that any possibility of leakage will be completely eliminated.

The use of a combination heater and nozzle was borrowed from ParCan's Inline Heater Nozzle Variation. However, instead of the heater resistor being mounted parallel to the path of the filament it is mounted perpendicular to the path of the filament. This was done to both reduce the length of the nozzle and to make it a little easier to run the leads from the heater resistor. Combining the heater and nozzle also helped to meet the goal to keep the number of custom machined parts to a minimum.

Advantages

- Internally, the filament path is identical to that of an already proven design.

- The design is simple as the number of custom machined parts is kept to a minimum.

- If necessary, the PTFE liner can be replaced by using an off-the-shelf piece of PTFE tubing.

- The PTFE is not stressed nor used to provide support. This reduces a point of failure that is part of other designs.

- A resistor is used as a heater. There is no need to wrap nichrome wire or to bake a heater core.

- Heat transmission is improved as there is no thermal junction where a separate heater screws onto the nozzle.

- With most versions weighing in at under 25 grams and the lightest version weighing in at under 13 grams, this design is very light.

- Significantly more reliable at printing PLA than other designs. The set screw on the PTFE ensures even compression for a good seal to the brass. PLA becomes soft at very low temperatures and is also a very good adhesive. Minimizing crevices and using a long non stick liner path is ideal.

Disadvantages

- Considerable machining is required.

- Not suitable for high temperature materials.

Printing Instructions and Tips

- The use of a cooling fan, for printing PLA, is highly recommended. If a cooling fan is not used, the chances of the hot-end jamming is greatly increased.

- Do not obstruct the airflow through the cooling vents or, with the Mk III-B, around the heat sink.

Suppliers

Differences Between Real J-Heads and Cheap Clones

- HotEnds.com <--- Original designer

- 3DMakerWorld.com US

- Charlie's 3D Technologies

- MakerFarm.com

- RepRap-USA

- Plastic2Print Europe

- reprapsource

- eMotion Tech reprap-france.com

- TriDPrinting.com HotEnds Seattle

- Ultibots Hot Ends

clones - removed see discussion page

Parts List

Mk I

Summary: First J-Head hot-end.

| Quantity | Part | Description | Part Number |

| 1 | J-Head Nozzle (v1.x) | Machined Brass Nozzle/Heater Combination, Version 1.x | |

| 1 | Nozzle Holder (v1) | Machined PEEK Nozzle Holder, Version 1.x | |

| 1 | PTFE liner (v1) | 1/8" ID, 1/4" OD PTFE tubing, Version 1 | McMaster-Carr 5033K31 |

| 1 | Heater Resistor | Axial, 5.6 ohm, 1%, 5W | UB5C-5.6-ND |

| 1 | Thermistor 1 | EPCOS 100K | B57560G104F |

| 1 | Support Washer | Optional 1/2" Fender Washer | McMaster-Carr 91090A114 |

Mk II

Summary: Added a hollow set-screw to retain the PTFE liner.

| Quantity | Part | Description | Part Number |

| 1 | J-Head Nozzle (v1.x) | Machined Brass Nozzle/Heater Combination, Version 1.x | |

| 1 | Nozzle Holder (v2) | Machined PEEK Nozzle Holder, Version 2 | |

| 1 | PTFE liner (v1) | 1/8" ID, 1/4" OD PTFE tubing, Version 1 | McMaster-Carr 5033K31 |

| 1 | Heater Resistor | Axial, 5.6 ohm, 1%, 5W | UB5C-5.6-ND |

| 1 | Thermistor 1 | EPCOS 100K | B57560G104F |

| 1 | Hollow-lock socket set screw | 5/16-24 hollow-lock socket set screw | McMaster-Carr 91301A150 |

| 1 | Support Washer | Optional 1/2" Fender Washer | McMaster-Carr 91090A114 |

Mk III

Summary: Added a heat sink in order to print PLA. To reduce weight, an aluminum nozzle is used.

| Quantity | Part | Description | Part Number |

| 1 | J-Head Nozzle (v2) | Machined Aluminum Nozzle/Heater Combination, Version 2 | |

| 1 | Nozzle Holder (v3) | Machined PEEK Nozzle Holder, Version 3 | |

| 1 | Heat Sink | Machined Aluminum Heat Sink | |

| 1 | PTFE liner (v1) | 1/8" ID, 1/4" OD PTFE tubing, Version 1 | McMaster-Carr 5033K31 |

| 1 | Heater Resistor | Axial, 5.6 ohm, 1%, 5W | UB5C-5.6-ND |

| 1 | Thermistor 1 | EPCOS 100K | B57560G104F |

| 1 | Hollow-lock socket set screw | 5/16-24 hollow-lock socket set screw | McMaster-Carr 91301A150 |

| 1 | Support Washer | Optional 1/2" Fender Washer | McMaster-Carr 91090A114 |

Mk III-B

Summary: Added a heat sink in order to print PLA.

| Quantity | Part | Description | Part Number |

| 1 | J-Head Nozzle (v1.x) | Machined Brass Nozzle/Heater Combination, Version 1.x | |

| 1 | Nozzle Holder (v3) | Machined PEEK Nozzle Holder, Version 3 | |

| 1 | Heat Sink (v1) | Machined Aluminum Heat Sink, Version 1 | |

| 1 | PTFE liner (v1) | 1/8" ID, 1/4" OD PTFE tubing, Version 1 | McMaster-Carr 5033K31 |

| 1 | Heater Resistor | Axial, 5.6 ohm, 1%, 5W | UB5C-5.6-ND |

| 1 | Thermistor 1 | EPCOS 100K | B57560G104F |

| 1 | Hollow-lock socket set screw | 5/16-24 hollow-lock socket set screw | McMaster-Carr 91301A150 |

| 1 | Support Washer | Optional 1/2" Fender Washer | McMaster-Carr 91090A114 |

Mk IV

Summary: Removed the heat sink and added a series of vents to provide cooling. To reduce weight, an aluminum nozzle is used.

| Quantity | Part | Description | Part Number |

| 1 | J-Head Nozzle (v2) | Machined Aluminum Nozzle/Heater Combination, Version 2 | |

| 1 | Nozzle Holder (v4) | Machined PEEK Nozzle Holder, Version 4 | |

| 1 | PTFE liner (v1) | 1/8" ID, 1/4" OD PTFE tubing, Version 1 | McMaster-Carr 5033K31 |

| 1 | Heater Resistor | Axial, 5.6 ohm, 1%, 5W | UB5C-5.6-ND |

| 1 | Thermistor 1 | EPCOS 100K | B57560G104F |

| 1 | Hollow-lock socket set screw | 5/16-24 hollow-lock socket set screw | McMaster-Carr 91301A150 |

| 1 | Support Washer | Optional 1/2" Fender Washer | McMaster-Carr 91090A114 |

Mk IV-B

Summary: Removed the heat sink and added a series of vents to provide cooling.

| Quantity | Part | Description | Part Number |

| 1 | J-Head Nozzle (v1.x) | Machined Brass Nozzle/Heater Combination, Version 1.x | |

| 1 | Nozzle Holder (v4) | Machined PEEK Nozzle Holder, Version 4 | |

| 1 | PTFE liner (v1) | 1/8" ID, 1/4" OD PTFE tubing, Version 1 | McMaster-Carr 5033K31 |

| 1 | Heater Resistor | Axial, 5.6 ohm, 1%, 5W | UB5C-5.6-ND |

| 1 | Thermistor 1 | EPCOS 100K | B57560G104F |

| 1 | Hollow-lock socket set screw | 5/16-24 hollow-lock socket set screw | McMaster-Carr 91301A150 |

| 1 | Support Washer | Optional 1/2" Fender Washer | McMaster-Carr 91090A114 |

Mk V

Summary: Reduced the size and increased the length of the melt zone. To reduce weight, an aluminum nozzle is used.

| Quantity | Part | Description | Part Number |

| 1 | J-Head Nozzle (v5) | Machined Aluminum Nozzle/Heater Combination, Version 5 | |

| 1 | Nozzle Holder (v5) | Machined PEEK Nozzle Holder, Version 5 | |

| 1 | PTFE liner (v1) | 1/8" ID, 1/4" OD PTFE tubing, Version 1 | McMaster-Carr 5033K31 |

| 1 | Heater Resistor | Axial, 5.6 ohm, 1%, 5W | UB5C-5.6-ND |

| 1 | Thermistor 1 | EPCOS 100K | B57560G104F |

| 1 | Hollow-lock socket set screw | 5/16-24 hollow-lock socket set screw | McMaster-Carr 91301A150 |

| 1 | Flat Washer | 1/4" OD Flat Washer | McMaster-Carr 98032A436 |

Mk V-B

Summary: Reduced the size and increased the length of the melt zone.

| Quantity | Part | Description | Part Number |

| 1 | J-Head Nozzle (v4) | Machined Brass Nozzle/Heater Combination, Version 4 | |

| 1 | Nozzle Holder (v5) | Machined PEEK Nozzle Holder, Version 5 | |

| 1 | PTFE liner (v1) | 1/8" ID, 1/4" OD PTFE tubing, Version 1 | McMaster-Carr 5033K31 |

| 1 | Heater Resistor | Axial, 5.6 ohm, 1%, 5W | UB5C-5.6-ND |

| 1 | Thermistor 1 | EPCOS 100K | B57560G104F |

| 1 | Hollow-lock socket set screw | 5/16-24 hollow-lock socket set screw | McMaster-Carr 91301A150 |

| 1 | Flat Washer | 1/4" OD Flat Washer | McMaster-Carr 98032A436 |

Mk V-BV

Summary: As the old thermistor was discontinued, the Semitec thermistor was substituted.

| Quantity | Part | Description | Part Number |

| 1 | J-Head Nozzle (v4.1) | Machined Brass Nozzle/Heater Combination, Version 4 | |

| 1 | Nozzle Holder (v5) | Machined PEEK Nozzle Holder, Version 5 | |

| 1 | PTFE liner (v2) | 1/8" ID, 1/4" OD PTFE tubing, Version 2 | McMaster-Carr 5033K31 |

| 1 | Heater Resistor | Axial, 5.6 ohm, 1%, 5W | UB5C-5.6-ND |

| 1 | Thermistor 5 | Semitec | 104GT-2 or 104NT-4-R025H42G |

| 1 | Hollow-lock socket set screw | 5/16-24 hollow-lock socket set screw | McMaster-Carr 91301A150 |

| 1 | Flat Washer | 1/4" OD Flat Washer | McMaster-Carr 98032A436 |

Mk VI-B

Not released due to cheap chinese counterfeits of J-head hot-ends. The innovation and production of new J-Head hot-ends has stopped due to chinese counterfeits that do not follow the specifications and have ruined the reputation of the product.

Mk 7-B

Not released due to cheap chinese counterfeits of J-head hot-ends. The innovation and production of new J-Head hot-ends has stopped due to chinese counterfeits that do not follow the specifications and have ruined the reputation of the product.

Mk 8

Only available through special order at http://www.hotends.com

Summary: Improved J-head with a better internal seal, axial thermistor, heater cartridge, and a fluted PEEK nozzle holder design. No kapton tape is required.

This design will not be publically released due to cheap chinese counterfeits of J-head hot-ends. The innovation and production of new J-Head hot-ends has stopped due to chinese counterfeits that do not follow the specifications and have ruined the reputation of the product.

Sundries

| Description | Part Number | Notes |

| PTFE Insulation For EPCOS or Semitec Thermistor, 0.012" ID | McMaster-Carr 5335K9 | |

| PTFE Insulation For Heater Resistor, 0.047" ID | McMaster-Carr 5335K15 | |

| 20 AWG High Temperature Wire | McMaster-Carr 8209K11 |

Note: *A good drill-chart for anyone with plans to make one can be found here http://whatisacnc.com/index.php?cID=241

Notes

Nozzle Orifice

Drill bit sizes and conversions

As drill bits usually drill holes slightly larger than their rated size, the following drill bits are used to drill out the orifice of J-Head nozzles:

| Rated Size | SAE Drill Bit Used | Actual Metric Size |

| 0.25mm | 0.0098 | 0.2489 |

| 0.30mm | 0.0118 | 0.2997 |

| 0.35mm | 0.0135 | 0.343 |

| 0.40mm | 0.0157 | 0.399 |

| 0.50mm | 0.0189 | 0.480 |

| 0.60mm | ||

| 0.70mm | ||

| 0.75mm | ||

| 0.80mm | ||

| 0.90mm | ||

| 1.00mm | N/A | 1.00 |

Notes:

- More sizes will be added as they become available.

- Smaller drill bits are used in order to keep the orifice size within the rated size and to increase the lifespan of the nozzle by ensuring that the orifice size will "wear to size" in the event that the orifice is slightly enlarged for any reason. (i.e. by cleaning with a piece of thin wire).

Nozzle orifice length

- Mk IV hot-ends (up to the middle of May 2012), and earlier models, had a nozzle orifice length of approximately 1.25mm.

- Mk IV hot-ends (after the middle of May 2012) and Mk V hot-ends have a nozzle orifice length of approximately 0.50mm.

Note: Due to the nature of 5c collets, the nozzle orifice length can vary as much as 0.25mm.