Joints for Delta Printer

Revision as of 03:03, 7 May 2014 by JKDesign (talk | contribs) (Created page with "DeltaCategory:Delta = Principle and Requirements = TBD The precision of nozzle positioning depends on rod length and a correct nodal point. = Varia...")

Contents

Principle and Requirements

TBD

The precision of nozzle positioning depends on rod length and a correct nodal point.

Variants

Cardan Joint

TBD

DIY Cardan Joint

TBD

PROs:

- Very low cost

- TBD

CONs:

- Precision depends on manufacturing and assembling. Little manufacturing and assembling error results in a much bigger nozzle positioning error

- Needs more space in construction

- TBD

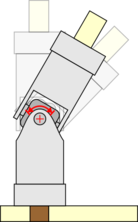

Industrial Cardan Joint

TBD

Main Problem:

PROs:

- Ready to use

- M4 or M5 threads

CONs:

- Cost per joint about 12 Euro

- Have to be mounted in 45° angle to minimize limits

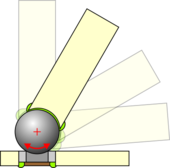

Rod End Bearing

TBD

Main Problem:

PROs:

- TBD

CONs:

- Limited printing area

- TBD

Magnetic Joint

TBD

PROs:

- TBD

CONs:

- TBD

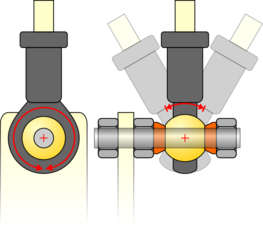

Magnet in Tube Variant

TBD

PROs:

- Low cost. About 1 Euro per joint

- TBD

CONs:

- Precision depends on tube cutting and deflashing

- TBD

Moving Ring Magnet Variant

TBD

PROs:

- Easy assembly

- Low cost. About 1 Euro per joint

CONs:

- TBD

Fixed Ring Magnet Variant

TBD

PROs:

- Easy assembly

- Low cost. About 1 Euro per joint

CONs:

- TBD