LaserCut Mendel Assembly

These assembly instructions are incomplete and have been posted by a customer rather than anyone associated with the sale of LaserCut Mendels. You may also wish to refer to the LaserCut Mendel Assembly Blog which shows some assembly pictures from another customer (in that case, only the laser cut parts are from techzone).

Extruder

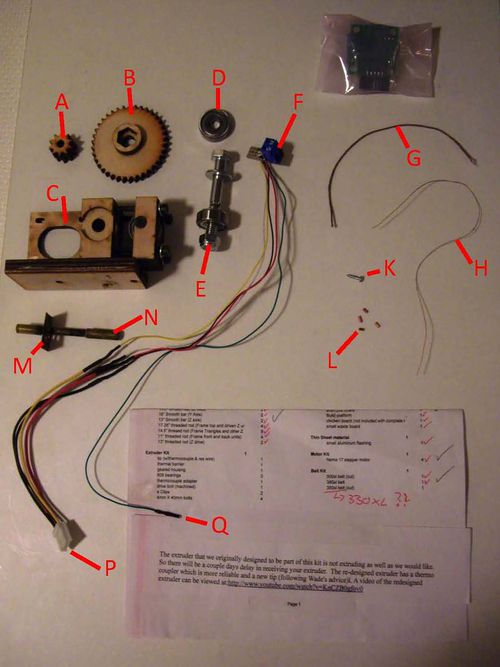

This picture shows all of the parts that go into making up the extruder.

If the tip of the extruder isn't assembled, go to the TechZone Tip Assembly.

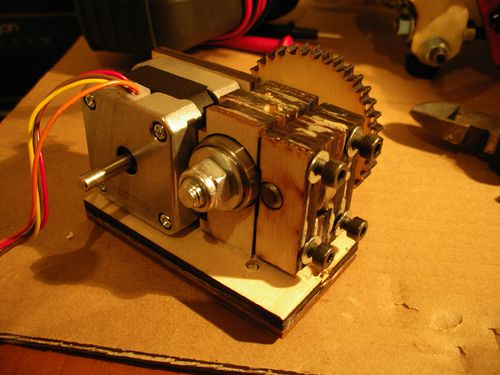

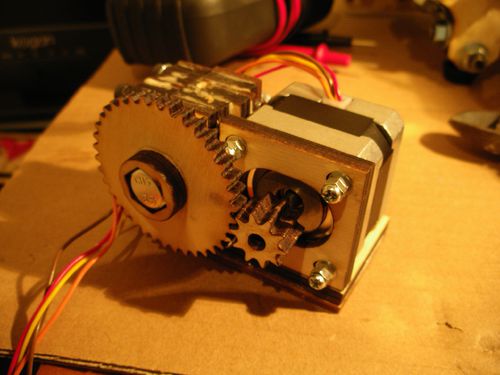

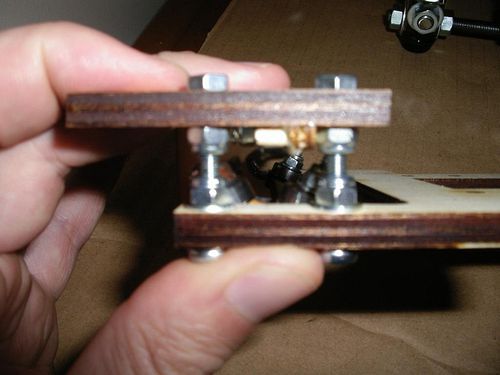

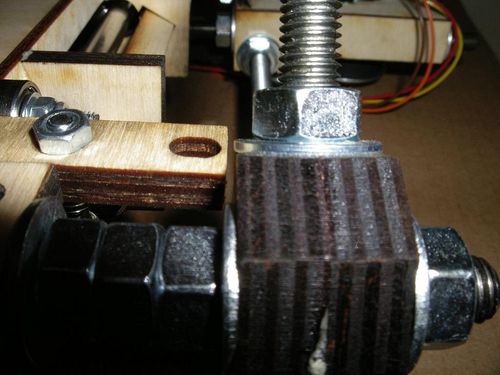

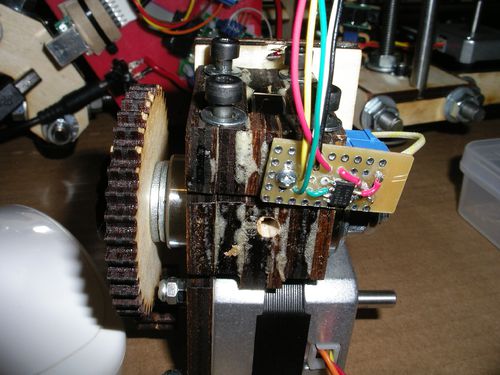

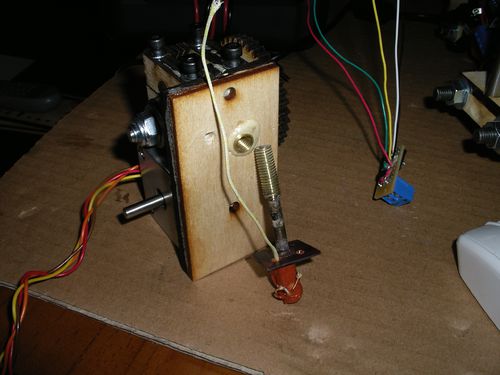

My extruder arrived mostly assembled. Here are a couple of pictures of it. The small drive gear is very wonky. It looks like the laser cutter was not cutting vertically when it was produced. I needed to put 2 washers between the bearing and the large gear to ensure that the knurled part of the bolt aligned with the bearing, extruder nozzle and filament hole.

I am unsure of how to mount this to the X Carriage and also how the extruder nozzle is supposed to attach to it. It screws in to the bottom, but the fit is fairly loose and there is nothing to screw it up against.

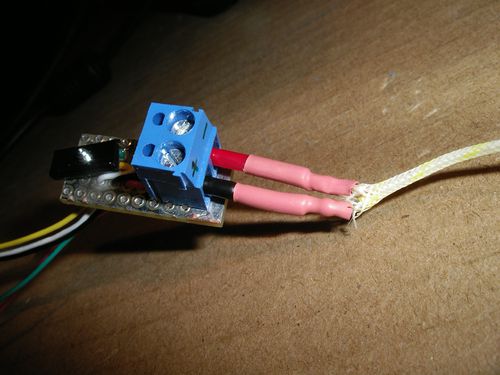

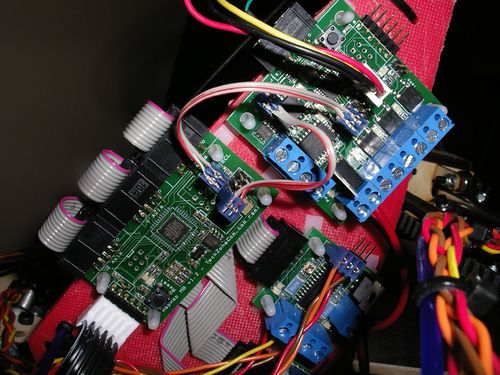

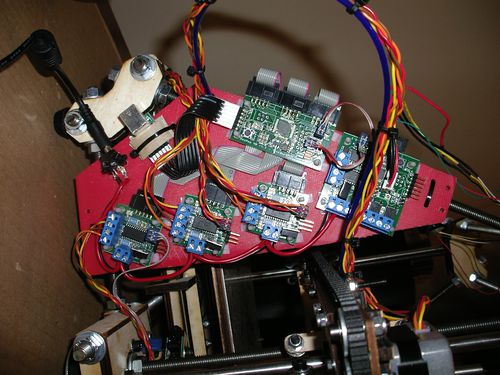

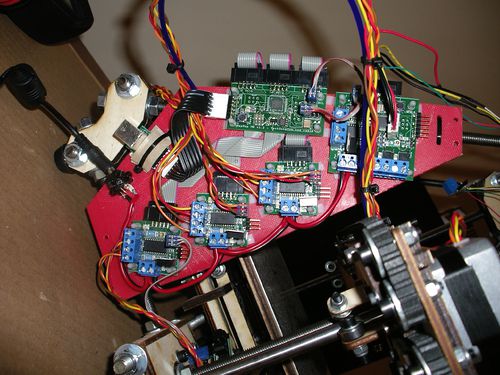

The thermocouple leads are quite small and difficult to clamp effectively in the screw terminals on the thermocouple board. To get around this issue, I soldered some speaker wire to the thermocouple leads, heatshrinked it and tinned the other end of the speaker leads. This provided something nice and meaty for the screw terminals to grab onto:

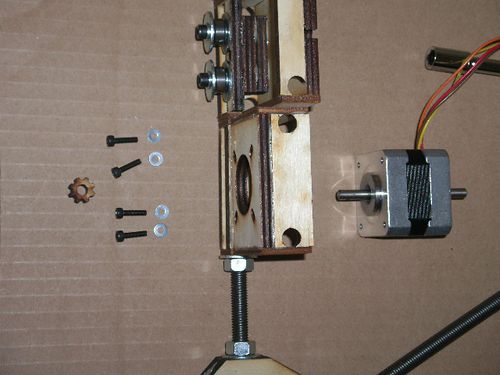

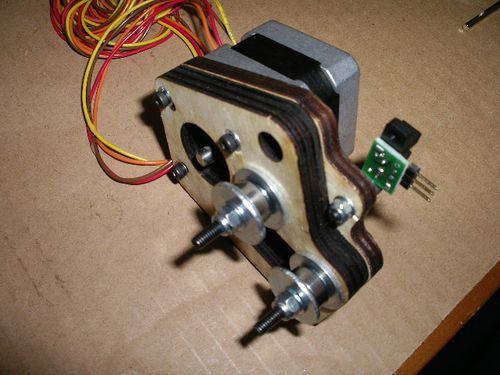

The kit didn't come with enough 12mm M3 capscrews. I had to get some more M3 screws from the local hardware store, and all they had were 15mm screws. As such, as you can see, I needed to add a couple of nuts to the screw in order to shorten the thread enough to firmly attach the extruder stepper.

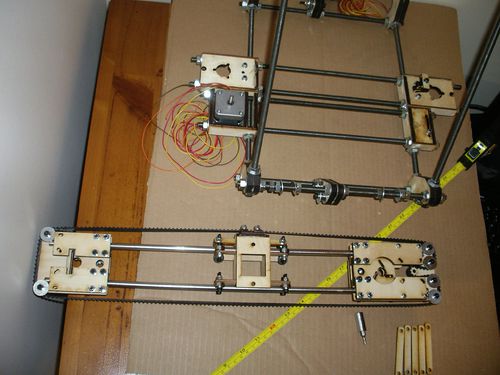

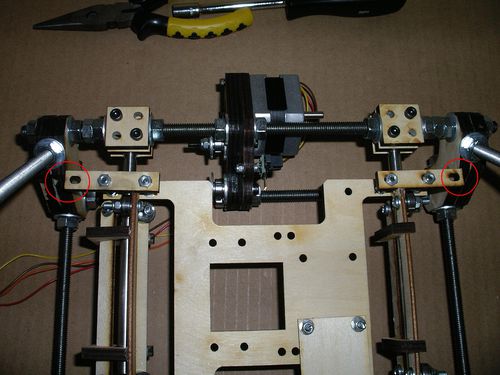

X Axis

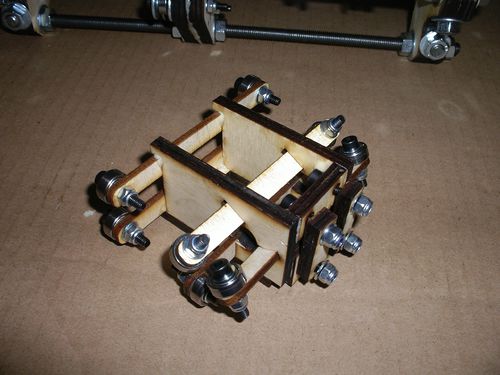

X Carriage

Tip: You will want to tighten two of the screws on the belt clamps (the ones shown at the bottom in the picture below) sufficiently to allow you to clamp the belt by only tightening screws at the top. This is because access to the cap head of the bottom screws is blocked by the bearing mounts once they are installed.

The X belt supplied by TechZone was barely long enough to go around the assembly. I installed the axis ends so that the smooth rods were almost touching the bearings (less than 1mm clearance). I still had to cut the belt and just clamp the ends on the x carriage to make it long enough to go round the assembly. Caution: This picture shows the X Carriage installed on the X Axis upside down (it shows the top of the X Carriage and the bottom of the X motor and 180 bearing mounts).

The X-Axis needs the longer machine screws to be able to go through the 3 pieces of wood and pinch the smooth rods in between. In the edges of the piece where the motor will go, washers don't fit well, so plan ahead for that.

After installing the X-Axis, I found that it is quite important how far apart the two ends of the X axis are spaced, so my efforts to compensate for the supplied X belt being too short resulted in the holes for the smooth rods not lining up with the rods. I saw this picture on someones Facebook build album showing how he extended the belt using a cable tie. I'm not sure how he attached the tie to the belt, but will be attempting something like that to make my belt fit.

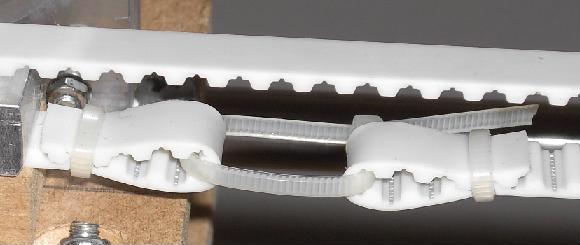

Photo of cable tie extended belt

The MegaMendel page has a photo and a description of the same extension using a cable tie. Here is a quote from that page:

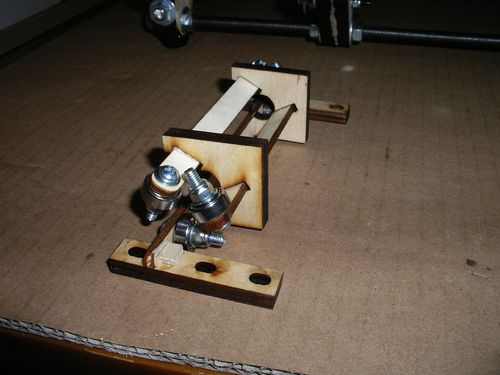

X and Y tensioners

You may not believe it:

Please note this after you're done laughing: They work like a charm - Never had a problem with them!!

Y Axis

Y Idler

Be warned that you probably need an additional washer against each bearing to allow the belt enough space for smooth running between the mudguard washers.

Y Motor

Be warned that you probably need an additional washer against each bearing to allow the belt enough space for smooth running between the mudguard washers.

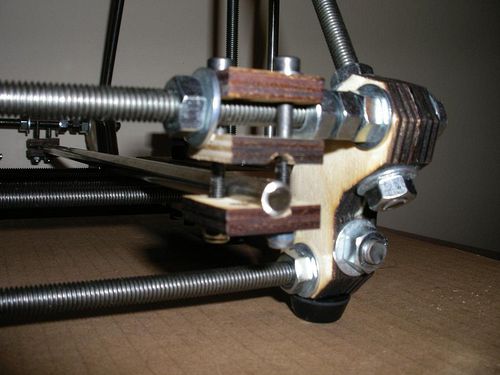

Y 360 Bearing

The clearance for this part is small, so make sure you don't use a screw that is too long for the upper bearing in the picture.

Y 180 Bearing

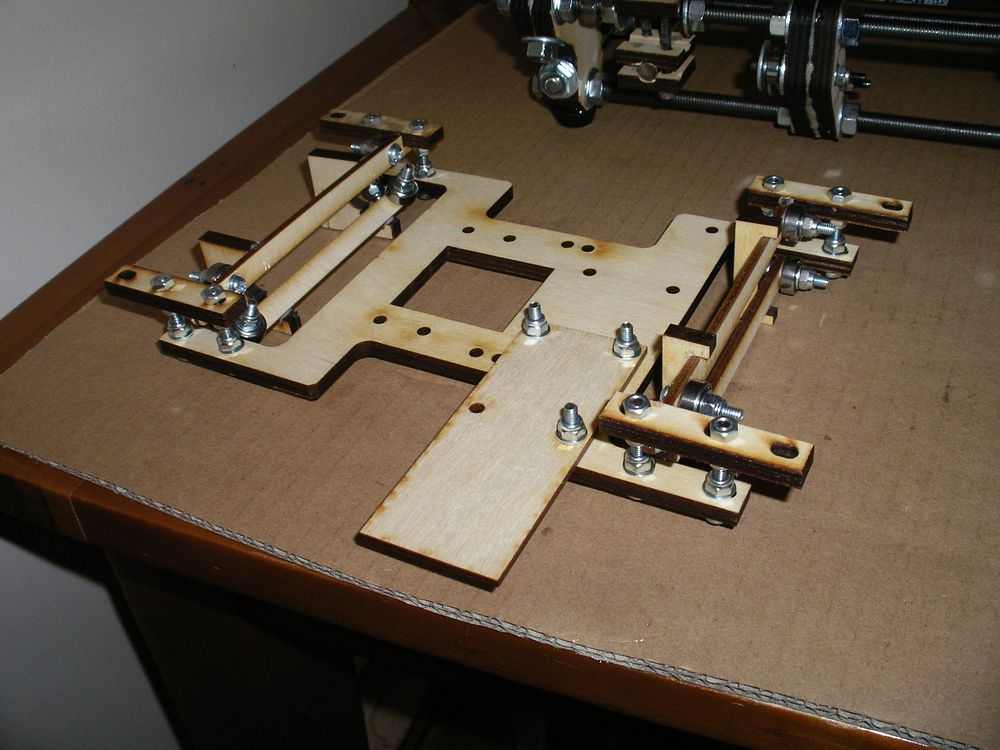

Y Chassis

I have found this to be the trickiest bit to work out without instructions, so I have left it till last. Consequently, I have used all of the shorter M4 screws that come with the kit and don't seem to have the right screws left to do this job (All I have left are lots of the M4x40 screws that only have thread on the last half). I think you are supposed to use the M4x30 Phillips Pan head screws to mount the Y 360 Bearing and the Y 180 Bearing to the frog plate?

For some of the intermediate nylock nuts used in the this assembly, I drilled out the nylock plastic to be able to get them on the machine screw back end first.

Z Axis

Z Leadscrew Base (one with opto)

You will need 2 of these assemblies, only one of them has the opto mount.

| Name | Qty /w opto | Qty /wo opto | Type |

| Z Leadscrew Base | 1 | 1 | Laser Cut Part |

| Opto Spring | 1 | 0 | Laser Cut Part |

| Opto Holder | 1 | 0 | Laser Cut Part |

| Bearing | 2 | 2 | Hardware |

| M4x40 | 3 | 2 | Fastener |

| M4 Washer | 9 | 8 | Fastener |

| M4 Mudguard Washer | 4 | 4 | Fastener |

| M4 Nut | 3 | 2 | Fastener |

Be warned that you probably need an additional washer against each bearing to allow the belt enough space for smooth running between the mudguard washers.

Z Motor

Z Tensioner

Be warned that you probably need an additional washer against each bearing to allow the belt enough space for smooth running between the mudguard washers.

Frame

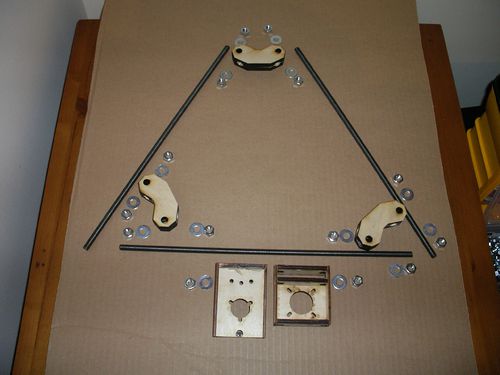

Frame Sides

Left Side

BOM

| Name | Qty/assembly | Type |

| M8 Nut | 14 | Fastener |

| M8 Washer | 14 | Fastener |

| 370mm M8 Threaded Rod | 3 | Hardware |

| corner vertex | 3 | Laser Cut Part |

| Z Leadscrew base | 1 | Laser Cut Part |

| Z Motor Bracket | 1 | Laser Cut Part |

You will also need a measurement jig to get the distance between the corner vertices the same. I created a jig using one of the other bits if M8 rod, 4 nuts and 2 washers. I assembled the jig so that the outside of the two washers was 290mm apart. Then used it when tightening the nuts on the vertex pieces to ensure the spacing was right.

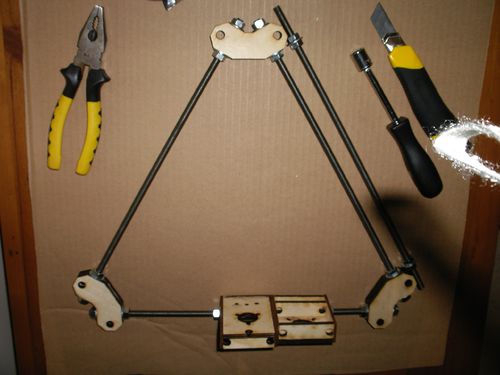

Right Side

BOM

| Name | Qty/assembly | Type |

| M8 Nut | 14 | Fastener |

| M8 Washer | 14 | Fastener |

| 370mm M8 Threaded Rod | 3 | Hardware |

| corner vertex | 3 | Laser Cut Part |

| Z Leadscrew base | 1 | Laser Cut Part |

| Z Tensioner Bracket | 1 | Laser Cut Part |

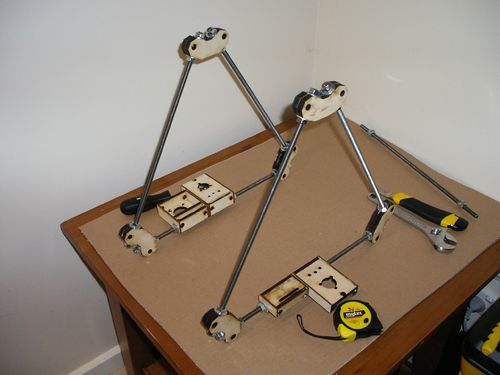

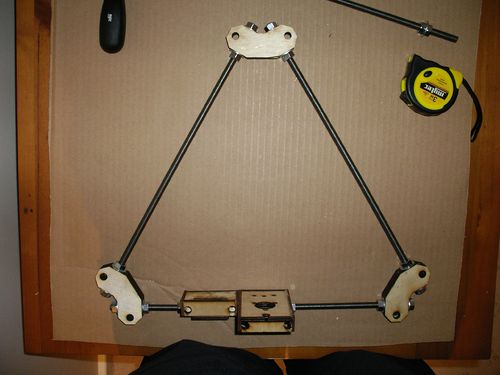

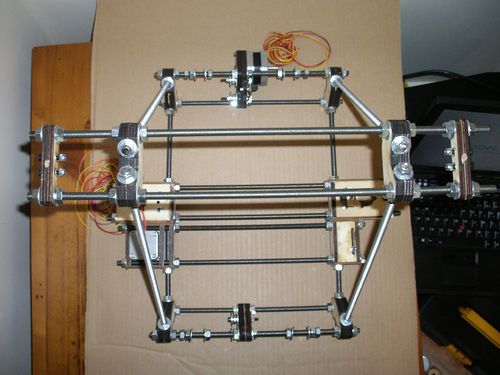

Assembled Frame

The pictures below show too many nuts on the front and rear bars. If you get the kit and do it this way, you will not have enough nuts. I was following the official Mendel build pics and it looks like they have too many nuts too (http://reprap.org/wiki/File:Frame-end-assembly.PNG).

Because the wood bites into the threaded rod really well, I didn't need to put any of the extra pairs of washers and nuts to keep the y axis in line (shown in the picture to the left and right of the Y-axis bearings and motor mount).

When putting this together I found that if I put the threaded rod in the chuck of my drill, I could put on 3 or 4 nuts on at a time.

Z Axis Installation

This is the same as the standard Mendel. Refer to the Mendel_frame#Installation_of_X-axis instructions.

Y Axis Installation

In order to get the Y Axis to sit properly with the Frog plate, be sure to get the orientation correct. The foot extensions for the plate should be up in the air. It took me a couple tries to get it right. Make sure you understand the orientation and to put the Y-Axis belt around the plate before tightening the second pair of mounts.

This shows the Y bars installed before the screws and M8 nuts are tightened. You can also see the rubber feet that I have epoxied to the four base vertices (these do not come as part of the TechZone kit).

Mechanical Construction Issues

I have assembled the Y carriage and installed it, but it looks like there is very little room for the Y carriage print bed mounts to fit between the base vertex pieces. Is the Y carriage supposed to have the full range of movement? Or should it be stopped before it passes between the frame vertices? I went ahead and used a hacksaw to chop a couple of millimeters of each of the print bed supports.

Printbed problem

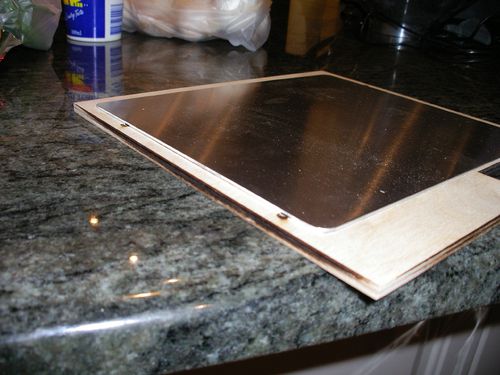

The Aluminium print bed sits (or is supposed to sit) in a routed recess in the laser cut printbed. Unfortunately, mine was too big for the routed recess. I needed to manually hack the routed recess with a stanley knife to make it large enough for the aluminium insert.

Once the bed is sitting flush in the recess, the width of the bed is still causing issues because it is partially obscuring the holes for mounting the bed to the Y Carriage. The kit creator suggests notching the printbed to allow room for the screws. The following pictures shows before and after the hole notching: