Lipsker Technology

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: unknown

| Description | Example Description.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Create your new page by logging in, editing the URL of any wiki page, and then clicking "edit". Please use this page as a model, or copy. You can get the "mediawiki text" by clicking "edit" on this page.

This page represents an example development page and showcases many features that can be used in creating new development pages.

Contents

Working Notes. This is a stub!

Everything below this point is working notes.

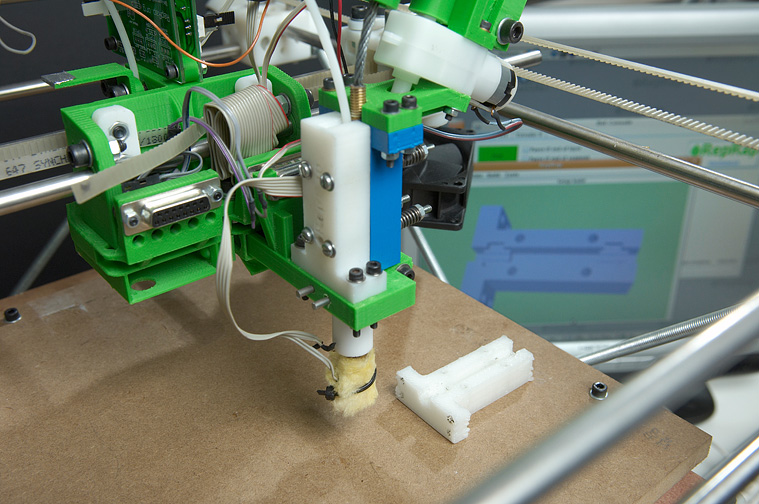

The development and prototype are unique and it differentiates from any other existing methods by doing the following:

- it takes any wire, thread, line or chord of any diameter and section

- it takes any existing thread or chord material

- it glues or welds it creating 3d layers of following geometry

- it can build limitless envelopes (including a real size house)

- it is not constrained to start building horizontally, IE: it can start at any surface and at any angle

- It does not require any closed environment

- Its accuracy and repetitive were around 0.1 mm

- the wires may be dynamically welded, stitched, glued or adhered

- the glues used may vary from single to bi-components and from heat to UV, from pre-preg to short wave.

- the system was built showing absolute results and was filmed by the Israeli Television - for the innovation and uniqueness.

- the smoothing results achieved were in direct relation to the wires diameter and the blob of adhesive between them

- the sytem includes an openGL and VCPP written software which analyses and creates the multiple paths for the wires - all as a single loop

Resources

- http://www.google.com/patents/about?id=PasFAAAAEBAJ

- http://www.rapidtoday.com/forums/viewtopic.php?f=2&t=311

- http://www.danylipsker.co.il/

Forum thread?

Process

What is making the part like?

Text (Motivation)

This is a generic Example project! I, (Example_User) made it because it's cool and Interesting, because I made it with a RepRap, because it is an innovative new RepRap, or because it is elegant or effective. Share and Enjoy! (This page was made using the wiki page Example as a model.)More Descriptive Text

Unlike Other Example project, this is different and better. But we borrowed many elements. Also, we like creating New Example projects.

Related Projects

Well, there's New Example. And Another Example.

Files and Parts

Sub Assemblies and Related

Example/SubAssembly and Related Example. (As a gentle style recommendation, it's good to try to keep all your parts and files on the RepRap wiki rather than scattered around so that Library Staff and Volunteers don't have to write scripts and so on to get stuff back onto the wiki.)

Downloads

- File:Uploaded files example.zip

- File:Even more example files.zip

- File:Example part.stl

- File:Other example part.stl

Photos and Drawings

Links can be put in captions.

More Examples

Entrepreneurship (Kits, Paypal)

(Example_User) may have a cottage industry making and selling kits. (S)he's also the developer. If you want to buy a kit, Example User is the best person to buy one from. So check out the homepage listed in the user box above.