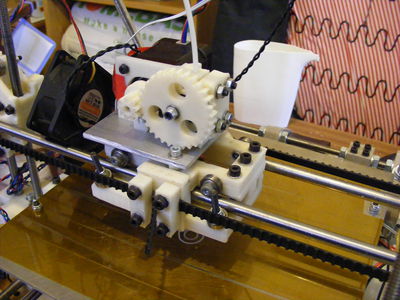

Mattroberts' Compact Geared Extruder

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: Working

| Description | Compact Geared Extruder

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Introduction

This page describes a compact extruder, similar to Wade's Geared Extruder and Adrian's Geared Extruder

Features

- Small size compared with both Adrian's and Wade's designs.

- Torque transmitted by M3 set screws / bolts, so low stress on reprap gears.

- Uses 624 bearings, and M4x40mm cap screws - the same as the rest of Mendel.

- Gear ratio of 9:31 - the co-prime number of teeth mean even ware.

- Easy to disassemble / remove from carriage.

What you need

- 1x each of the RP parts (except, possibly base.stl)

- 3x 624 bearings

- 5x M4x40mm bolts

- 3x M4x16mm bolts

- 13x M4 washers

- 6x M4 nuts

- 3x M4 nyloc nuts

- 5x M3x10mm bolts

- 2x M3 washers

- 2x M3 nyloc nuts

- 4x M3 set screws - I made mine by cutting some M3 bolts with a dremel

- 4x M3 nuts

If you have built a Mendel, you will have plenty of the correct size nuts, bolts and washers.

Construction / Drive Shaft

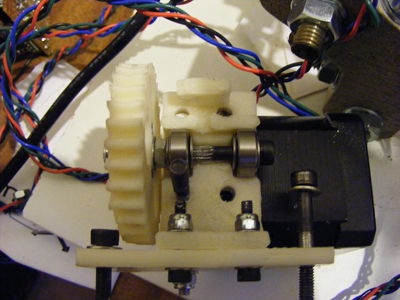

The construction is fairly easy - the openscad source file will generate an assembled extruder for you to look at. The hardest bit it building the drive shaft.

When the drive shaft is built, it should look something like this:

I used an M7x1.0mm tap to hob the bolt to provide drive to the plastic.

The order of things on the drive shaft (from left ot right) is:

| M4 nyloc | M4 washer | driven gear | M4 nut (within gear) | M4 nut (locked to previous nut) | M4 washer | 624 bearing | M4 washer | hobbed gap | M4 washer | 624 bearing | M4 washer | bolt head |

Modifications

You could use an M4 hex bolt with the gear the other way around to provide drive - then you wouldn't need the the two M4 locked nuts.

If you have a stainless steel hot end, it makes sense to replace base.stl with alluminium, combining the heatsink with the extruder base. This works and can be seen in the main photo.