Mechanical Rigidity

Mechanical Rigidity

This page goes into the basics, with illustrations, on how to ensure that a design is mechanically rigid, and also what to look for if buying an existing 3D printer. The key elements are:

- Rigidity must be achieved in all six degrees of freedom: Rotation about each of X, Y and Z, and Movement in X, Y and Z.

- The simplest rigid open structure is a triangle.

- Solid materials (plates, bars, extrusions, rods etc.) have rigidity that is proportional to their thickness (or length)

- A "lever" effect on the way that the frame is connected together is critical to take into account.

Thus, a quick guide to analysing an existing design is:

- If it is a cube design, is there support in all six faces of some kind? Either plates (polycarbonate, acrylic, plywood or hardboard at least 2.5mm thick) filling each face, or aluminium plate of sufficent thickness (minimum of 3mm depending on printer size), diagonal struts creating complete triangles, or even suitably strong and high-tension wires (again creating complete triangles to all vertices)

- If it is a Mendel style design, these are not rigid at all in their base, and rely completely on being on a flat surface, with gravity assisting to keep them down.

- If it is an "open design" without triangles (or plates), is the frame of sufficient thickness for the size (3020 for a 200x200 printer, to 8020 extrusion for a 300x300 or greater) and are the frame struts sufficiently strongly connected together?

Examples

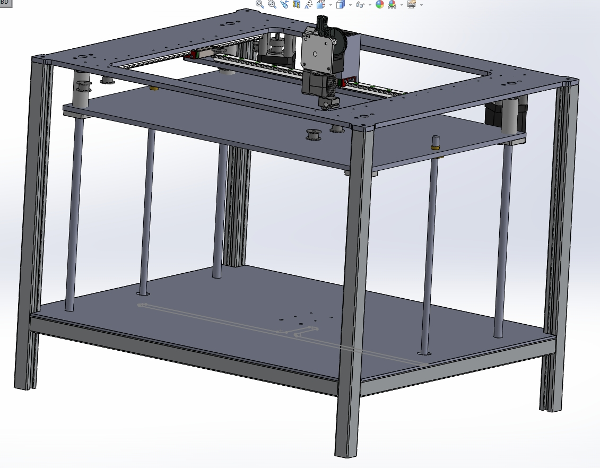

Cube design needing improvement

Here is a design where some advice was asked here http://forums.reprap.org/read.php?177,722199:

Analysing each face:

- The base is fantastic, it is entirely rigid. The bottom face therefore cannot "shear" (become a parallelogram).

- The top face is also excellent: the aluminium plate, despite having a hole for the X-Y assembly, is of sufficient thickness and the hole is no so large so as to reduce the rigidity of the aluminium plate as a frame, so as to provide complete rigidity in the top.

- However the open sides mean that the entire assembly may be "twisted" or "sheared": any one of the four sides may become a parallelogram, resulting in the entire frame being completely flexible.

Note that there are no corner braces in this design, on any of the uprights, so there is absolutely nothing to stop the twisting and shearing. "Twisting" may be demonstrated by securing the four feet of the cube to the floor, then taking the top and trying to "unscrew" the whole assembly as you would a jar's lid. With this type of cube design if any one side is left open, then like a cardboard box where the top is open, all efforts spent on rigidity of the other five cube sides are entirely wasted: it is essential that all six sides are made rigid.

So as described in the forum thread, fixing this design to make it rigid may be achieved by:

- Filling in all four remaining sides with some form of panel. Although acrylic or lexan provides internal visibility, even 3mm hardboard or MDF is sufficient for this purpose, and even 1.5mm plywood would suffice if, along the actual frame, the plywood is doubled up so as to spread the load of the bolts (with thin plywood, washers would be inadequate), and there are attachment points at least every 80-100mm on every single piece of the frame. Particular attention needs to be paid to ensure that there is good friction between the frame and the panel.

- If however there are large holes to be put in the panels (so as to provide visibility or access) then thin materials such as hardboard, MDF or plywood are not sufficient, not least because these cheaper materials are subject to expansion under different temperatures and humidity. Better materials would be aluminium or other metal, lexan, acrylic and so on. The required thickness of the panel with a large access hole will depend on the size of the printer. For a 200x200 printer a minimum of 5mm material should be considered and a minimum of 40mm border, with more than that at corners. A good example is the Ultimaker 2 (see below).

- Adding diagonal struts from corner to corner in all four faces, ensuring that the struts do actually go into the corners instead of some distance along one of the other frame pieces. Attaching the diagonals to both the horizontal and upright parts of the frame is best.

- Replacing the upright struts with much thicker extrusion (30x30, 40x40) and then ensuring that they are braced properly in the corners. This means using beefy triangular braces (40x40mm or greater) or drilling sideways through the extrusion and using an allen keyed hex bolt to attach it to the centre hole of the piece that it is to be attached to. For this particular trick to work the ends of the extrusions must be absolutely dead flat.