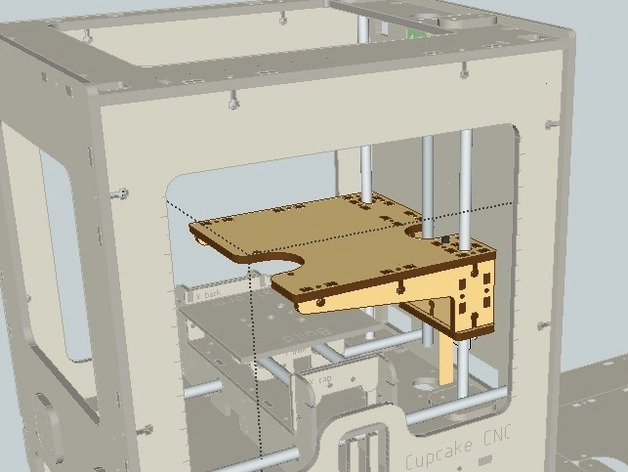

Mechanical Rigidity/Boxframe Cantilever Printbed

Laser-cut acrylic / wood, single lead screw, dual rods cantilevered design

There is an innovative upgrade to the Cupcake CNC which is based around laser-cutting of thick acrylic / wood:

- The use of sturdy (6-8mm thick) laser-cut panels means that no bending / flexing will occur

- The rods look like they are either 10 or 12mm and there are two large bearings one under the other on one side

- The printbed is supported underneath on three sides so will not flex.

All in all this is a surprisingly good design, despite the left-hand rod only having one bearing where the other side has two. Improvements to this design would involve creating a full "box" structure entirely surrounding the bearings, expanding the depth of the box so that there is at least 70mm separation betweeen the bearings, and using four bearings (two per rod) instead of just three. This would ensure that both rods are used to prevent rotation about the Y-axis of the entire assembly, whereas in its current incarnation the right-most rod with two bearings is exclusively responsible for preventing rotation.