Mechanical Rigidity/Folgertech Kossel Bracing

Bracing on Folgertech Kossel designs

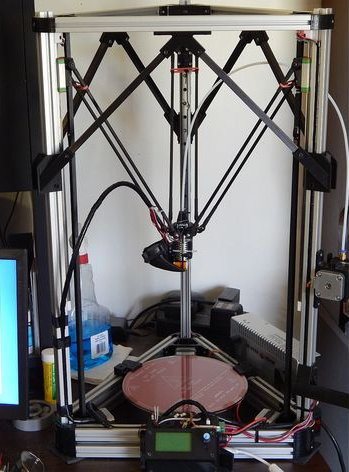

An attempt to improve the Kossel has been made, to brace the uprights:

This design has significant triangular bracing on all three uprights, which successfully alleviates the "parallelogramming" inherent in a toblerone-style frame. In this particular modification the bracing (which is at the top) is done in such a way so as to not interfere with the operation of the printhead.

However, what this bracing does is simply rely on the structural strength (rigidity) of the 20x20 extrusion, which as it is particularly long on Delta 3D printers, becomes a bit of a problem. If however the 2020 uprights were replaced with 30x30 or even 40x40 then this would no longer be a problem. Note that the horizontal parts would also need to be replaced, because the load from each triangle is transferred to the middle of each horizontal part, without that point then being braced vertically. One way to fix that would be to have a second set of horizontal parts at the top, filling the three gaps with panels... or to just use 8020 extrusion instead.