Mechanical Rigidity/Horizontal China Clone Carriage rework

Rework of a truly dreadful China clone from vertical into horizontal carriage arrangement

Originally beginning from a quick search on thingiverse a replacement set of X-ends and carriage had to be developed to recover the parts from an otherwise completely unusable 3D printer ordered from taobao: http://www.thingiverse.com/thing:71279

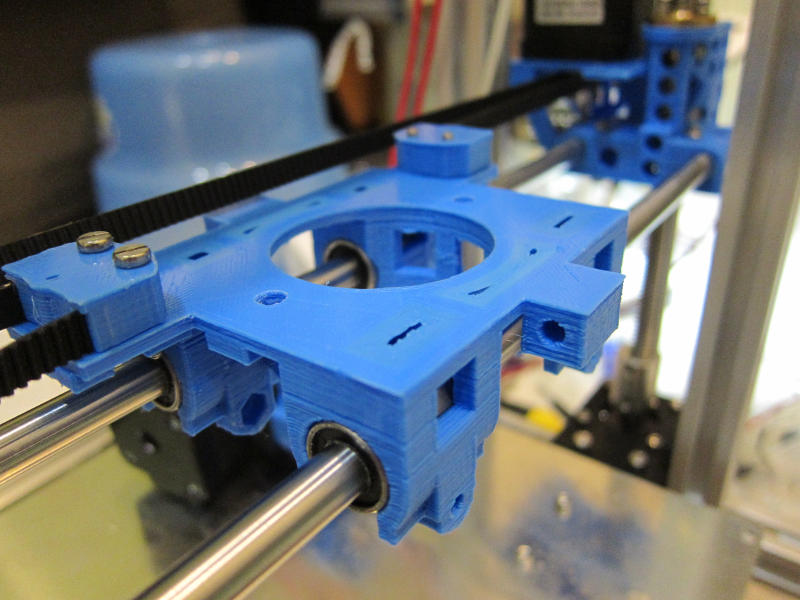

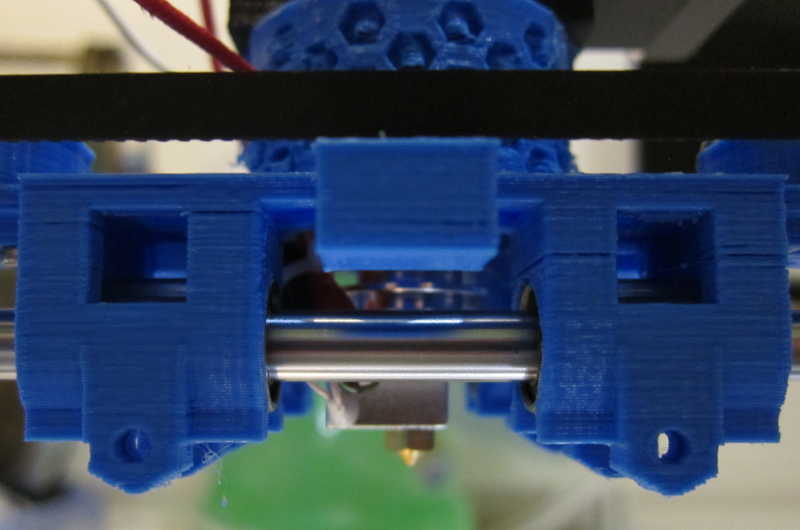

In the pictures below the following can be seen:

- The carriage is mostly full of holes (saving significantly on plastic), is compact (45mm between centres, leaving plenty of room for even a large hotend, and only 76mm wide), yet has bracing in strategic areas where it matters. Actual weight in plastic is 34 grams.

- The nozzle is specifically arranged to be dead-centre of the carriage, and only 15mm below the centre line of the two rods.

- The actual X-ends have been drilled with holes that reduce their weight to only around 40 grams, but again without reducing their effectiveness and strength.

This means that any "play" in the linear bearings (which tend to be absolutely dreadful) is not amplified by any "lever effects". The disadvanges usually quoted as the reasons for going to a Vertical Carriage arrangement therefore do not apply.