Mechanical Rigidity/MendelFlex

MendelFlex

The MendelFlex is a modified version of the original Mendel concept, replacing rods with 2020 extrusion and adding a "box" at the base.

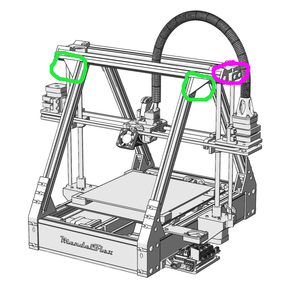

- The triangles of the original Mendel concept are replaced with near-triangle-shapes: rhomboids with a very small top (in effect a triangle with the tip cut off). This does mean that there could theoretically be some movement (see purple ring) but in practice there are no lateral forces during movement which would affect print quality.

- The rectangular faces are adequately braced in four places (see green rings) with 40x40 corners (in exactly the way that is recommended to improve the 8020 Ox). which transfers any parallelogramming to a load (bend) on the top 2020 extrusion.

- The base is a "box" that has panels entirely filling it in on all sides and also the base. Normally a "box" with only 5 closed sides would still not be rigid, but in this case any "twisting" (such as trying to lift one corner only) would transfer through the triangular uprights (as parallelogramming of the toblerone rectangles), and this would be prevented by the 40x40 corners.

Also it has to be noted that in this design the use of a Flex3Drive results in significantly reduced inertia of the printhead, and in combination with the bracing and good design of the MendelFlex frame it can be operated at a sustained speed of 350mm/sec - well above what even a stock Ultimaker-2 can achieve.