Mendel90

Revision as of 06:50, 4 March 2012 by AdrianKelly (talk | contribs)

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

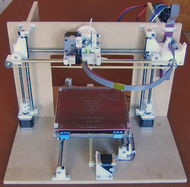

Mendel90

Release status: Experimental

| Description | A Mendel with flat sheets at 90 degree angles

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Mendel90 is being designed by Nophead to replace many of the threaded rods and printed parts of the [Prusa Mendel] with flat sheets, either MDF or Acrylic. It's advantages compared to the Prusa Mendel are:

- Stiffer, especially in the X Direction, so it can go faster without vibration

- Much less calibration and jigging required; if your holes are in the right places, your rods will be parallel

- Can be drilled with a paper template to make sure all holes are perfect

- Sheets are usually straighter and flatter than rods, as they are thicker and much wider

- All the OpenSCAD files are fully parametric; you can set all the parts to whatever sizes you want and easily increase the build area

- Everything is mounted on one of two planes, so it's all flat

- Frame is held together throughout the machine, instead of just at the corners, so much less warping

- Less vitamins

- Open design, allowing it to be worked on easier and mostly dissasembled without falling apart

- Z axis motors are at the bottom, so that the couplings don't need to support the weight of the X axis

- This means the Z couplings can be smaller, and therefore Z smooth rods closer to the threaded rods, increasing stiffness

- The center of balance is also lower, making it more stable

- Less printed parts, so it can be printed easier and faster

- Parts are ribbed to maintain strength and decrease print time

- Ribbon cables are used to prevent cable tangling and friction

- Rectangular, so it can be shipped and put in Heated Build Chambers easier.

- Uses LM8UU bearings

- Uses 10 instead of 12, so only one package is needed

Disadvantages:

- If you drill a hole wrong, it is much harder to fix than to adjust a nut on the Prusa Mendel

- Less room for adjustment-only a few mm

- Harder to expand to a larger build area once built

- MDF expands with heat and moisture, and Acrylic cracks-MDF could be coated with Epoxy

- OpenSCAD files have not been released as of March 4, 2012-they will be on Github

- More volume of vitamins-sheets are larger than rods

- Probably heavier and harder to ship

- More types of screws

- Louder because sheets act as soundboards

- Fewer bearings might make it less accurate