MendelMax

Release status: working, but needs user feedback.

| Description | A true reprap; printed brackets, with the rigidity of aluminium extrusions.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

PLEASE NOTE: The official MendelMax documentation is maintained at MendelMax.com. Please refer to that site for the most authoritative documentation.

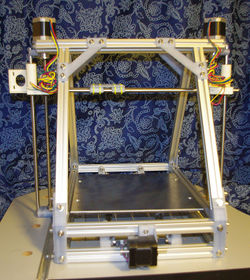

MendelMax is a new Open Source RepRap 3d printer designed by Maxbots. It is a true reprap, using printed brackets, but instead of using threaded rod for the structural elements it uses inexpensive aluminum extrusions. This gives a huge increase in rigidity for a minimal extra cost (Self sourcing will cost about $80 more than a standard Prusa when purchased from the recommended suppliers). The required extrusions are available world wide from a variety of suppliers.

MendelMax is based on the Prusa Mendel, and keeps its best parts. The Prusa Mendel kept the frame of the Sells Mendel, but fixed the problems in the X,Y and Z axes. MendelMax builds on that by largely keeping the current XYZ axes, but completely redesigning the frame.

In addition to the increased rigidity, the printer is much easier to assemble than a standard Prusa. Even an inexperienced builder should have no trouble building the whole frame in an evening, two at most. And along with the easy assembly comes easy hackability. Almost any part on the bot can be removed with just a few screws, so swapping out literally any part on the bot is now a trivial operation.

The X axis is taken stock from the Prusa Mendel, in fact we don't even specify a specific X axis design, there are several good ones available, including the various vertically-orineted X axis designs that many people are exploring lately. As long as it sticks to the defined standard spacing between the Z rod and the Z leadscrew, it will work fine with MendelMax. We also use the standard Prusa Y design, though we simplify it just a bit by making it easier to get everything aligned right. Z adds optional thrust bearings to support the weight of the axis (greatly reducing the problems with printed couplers), but this is a purely optional upgrade, and you can easily use the old design if you prefer.

Because MendelMax is primarily defining a new frame design, it is linear-bearing agnostic. I have used both LM8UU's and PTFE bushings and both work just fine. Brass or even printed bushings could be used, though I recommend avoiding the latter for highest reliability.

Links

- Lots of pictures, including of the assembled printer and several finished prints here.

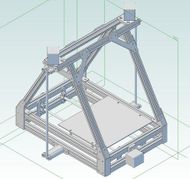

- 3D PDF (View with Adobe Acrobat, most 3rd party viewers do not support 3d PDFs. Click on the image to view in full 3D, pan, zoom, rotate, etc.)

Community

- For more information, visit our FreeNode IRC channel at #MendelMax (or ask in #reprap). Please be patient, this is presently a low-volume channel so it may take a while to get responses but someone will help you as soon as possible.

- Please join our Google Group.

Files

- STL Files can be downloaded from thingiverse

- FreeCAD SCAD source files are available at the MendelMax GitHub repository.

- A full Bill of Materials (BoM) is available on Google Docs

- Assembly instructions and lots more information are available on the MendelMax homepage.