Merlin Hotend

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: working

| Description | Short hotend with replaceable airbrush nozzels

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Introduction

- "When I started my journey into 3D printing early in 2011 it was by taking part in a workshop by GRRF (now GRRG). The kit was for a classic mendel with laser cut wooden parts.

- Within the two days of the workshop it was nearly impossible to glue all parts together and assemble them into a working printer, however I came back with what resembled a 3D printer.

- It turned out there was a lot of work left before I could say I had a working 3D printer.

- Several mechanical problems of the wooden Mendel made it impossible for me to make the machine work reliable and precise, thus I quickly decided that a better one is needed.

- The MK2 was build from a 30mm aluminum profile cube.

- Having completed the working printer in 2012 the next obstacle was the hotend.

- The modular hotend from GRRF just did not cut it. It was unreliable and tended to clog up. With the help of my friend Jo and his workshop i got into creating an own hotend.

- There were many people claiming that long nozzles would allow for the best flow of material, others claimed that serious cooling would be necessary.

- As it turned out the perfect recipe for me was quite different.

- I ended up with a design that is short and requires no cooling for most purposes. In thanks to my tomcat Merlin, who kept me sane during some pretty crazy times when nothing worked as expected, I named it the Merlin hotend."

-- Björn Marl ("Srek")

Print examples

TODO: Put some more pictures of pretty printed things here as soon as the copyright questions are solved.

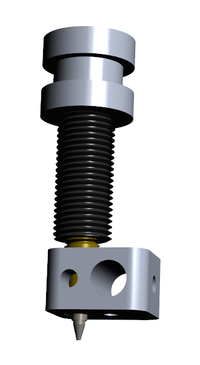

Assembly

Regardless if you build it yourself or bought the hotend, you need to make sure of a few things when assembling it.

1. Doublecheck that the parts are clean, especially small PTFE parts can quickly jam the nozzle.

2. Make sure the inlay is screwed into the PEEK part deep enough, the upper end should sit flush in the PEEK.

3. Tighten the brass nozzle enough so it sits tight against the PTFE, check that a little bit of threading is still visible so you know it sits tight against the PTFE, not the PEEK. If you don't tighten this sufficently you get a small gap between PTFE and brass which will allow plastic to escape.

You can check the tightness by inserting some filament in the cold hotend, if you can easily push it right down to the end of the brass it isn't to tight. If it stops within the PEEK part it is to tight.

4. When inserting the thermistor take care to not damage it

5. Glue the thermistor in place using red seal, or similar heat resistent flexible glue. You can get away with thermal paste, but you have to make sure that the thermistor stays in the heatblock using different means then.

6. Make sure the thermistor leads are sufficently insulated using heat resistant insulator. You can use small PTFE tubes.

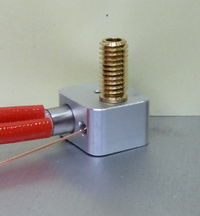

Heaterblock assembly

Some requested more detailed info on the assemling of the heater block.

Attached you can see the heater block as it comes with the Merlin Nozzle from Reprapdiscount and how the components belong together. You should use a thermal glue or heat resistent silicone to mount the thermistor.

Using thermal paste for thermal conductivity and kapton tape to fixate it can work, but it is not a lasting solution. Also make sure that the wires of the thermistor are correctly isolated, especially if you use thermal compound, since that is often conducting electricity.

You can use very small PTFE tubings to isolate the thermistor contacts, thermal glue to fix the thermistor and kapton tape to hold it all together.

This is how a heater block might look after a couple of rolls of different materials and some rough handling. Please note that it still works just fine.

Cooling

The Merlin is designed as a passive cooling hotend. Nevertheless, some users experienced problems when printing PLA without cooling the hotend.

The Merlin kits sold by reprapdiscount and fabber-parts contain a 40mm fan for that purpose.

Sources

- Fabber-Parts.de (maybe you want to google some opinions before ordering)

Parts

Here you can finde the PDF files with contruction schematics. The hotend is made up of the following parts:

14 mm long 16mm diameter aluminium mount

20 mm long 6mm diameter brass nozzle

The brass part is threaded with M6 on the upper half.

Drill diameter for 3mm filament is 3.2mm, for 1.75 filament it is 1.9mm.

Drill depth is ca. 18mm, you need at least 2mm material remaining at the lower end.

For the airbrush nozzle a hole with M 1.75 thread is needed at the lower end.

M1.7 is not the exact size of the thread of the airbrush nozzle, it makes sure that the nozzle sits tight and does not leak. If you were to use the correct thread the nozzle would leak and possibly unscrew itself during printing.

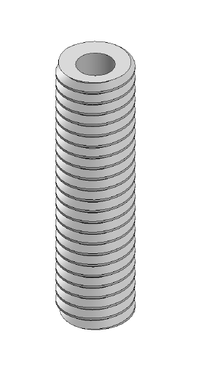

30 mm long 10mm diameter PEEK Heatbarrier

The PEEK part needs an outer M10 thread and an inner M6 thread. When drilling or machining PEEK take it slowly and use a lot of coolant/lubricant.

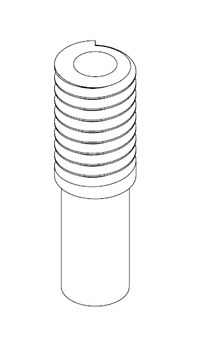

20 mm long 6mm diameter PTFE inlay

The PTFE part needs an outer M6 thread.

Drill diameter for 3mm filament is 3.1mm, for 1.75 filament it is 1.8mm.

Heatblock for 6mm diameter nozzle, 10mm thick

... and 1 pcs. Airbrush Nozzle

Mounting

The Merlin hotend comes with a J-Head compatible Groove Mount.

Annother approach is a slightly modified wade's extruder. By printing this and cutting a M10 thread into the cold end the Merlin can be mounted directly to the extruder. This will result in a really, really shot hot end (about 25mm remaining length).

Additional Links

License

All information regarding the construction of the Merlin hotend is provided under CERN OHL 1.2. This hotend is open hardware, everyone can make an own version for personal or commercial use.