North90's hot-end

This hot-end is designed to be build with simple tools and without the need for great engineering skills.

Contents

About the design

WHY another design? The complexity of most hot-end designs (lathe needed) and the use of hard to obtain and expensive materials (Peek) make it hard for the average person to build their own hot-end. This design is great for everyone who wants to build a hot-end but who doesn't have access to a lathe, cnc-machine and drill-press.

Thermal design

Each hot-end consists out of three main parts:

- hot end where the plastic is melting (usually brass tube + nozzle)

- insulator which keeps the heat away from the extruder (usually PTFE(=Teflon) rod)

- cold end the cool part of the hot-end which mounts to the extruder (can be any kind of material)

This hot-end uses stainless steel as an insulator. Stainless steel conducts heat less easily than normal steel, brass or aluminum, but much better than PTFE.

| MATERIAL | THERMAL CONDUCTIVITY W/(M*K) | NOTES |

|---|---|---|

| PTFE | 0.25 | will deform when hot: can't be used as structural part |

| PEEK | ~0.25 | expensive+hard to obtain |

| normal steel | 45 | |

| stainless steel | 18 | |

| brass | 120 | |

| aluminium | 220 | |

| dry wood | 0.05-0.12 |

from http://en.wikipedia.org/wiki/List_of_thermal_conductivities

The thermal conductivity of stainless steel is about a 100 times larger than that of PEEK or PTFE. To have a similar insulation as a PTFE insulator the cross-section of the insulator has to be a 100 times smaller.

A normal 16mm PTFE insulator (with a 3mm hole) has a cross-sectional surface area of 194mm2. The heat transfer for a PTFE insulator that is 25mm long at a temperature difference of 200C is 0.38W.

The stainless steel insulator of this hot-end is 6.35mm outside and an inside diameter of 5.7mm has a cross-sectional area of 6.14mm2. The heat transfer for this insulator (25mm long and 200C) is about 1.1W. This is almost 3 times as high as the PTFE insulator of the same length.

The extra heat transferred through the stainless steel insulator has to be dissipated with a heat sink.

Tools and supplies

- Drill + drill bits

- Vice

- Tap and die set: M3 tap, M6 tap and die

- Tube-cutter (or fine metal saw)

- File(s)

- Cutting oil (olive oil works great)

- Stainless steel tube with an outide diameter of 1/4" (6.35mm), inner diameter is not important

- PTFE tube 1/8"(3.18mm) id and 1/4" (6.35mm) outer diameter

- M6 brass bolt (25mm long) or welding nozzle (0.6mm)

- piece of aluminium 5-6mm thick

How to build the stainless steel insulator

Cut a piece of stainless steel tube of about 55mm long (about 10mm longer than the insulator you are making). An easy and very clean way to cut the tube is to use a tube-cutter. Stainless steel is very hard so it will take a while to get through. Use (olive) oil to ease the cutting Personally i put the tube in the drill and let the drill do the hard work.

Next step is to drill the inside of the stainless steel end up with an inner diameter of 5.5-5.6mm.

- Put the stainless steel tube in the drill and the drill-bit in a vice.

- Only reduce the inner diameter of 45mm of the tube, leave the last 10mm the original size. The tube gets to fragile to work with when the whole tube is drilled out. The last 10mm is cut off at the end.

- Drill the tube out in small steps: if the inner diameter is 4mm use a 4.5mm drill to start with followed by a 5mm and a 5.5mm drill.

- Use loads of oil (olive oil works great) to save your drill bits and make cleaner cuts.

- Go slow, try to get long pieces of metal coming out of the drill instead of small pieces.

When the tube is drilled out to 5.5mm inner diameter, one end is threaded with m6 thread, to be able to attach the hot end. Put the tube in the vice and use a M6 tap to tap thread in the drilled out end of the insulator. Use plenty of oil and go half a turn in, quarter turn out, half a turn in, quarter turn out. etc. Tap the tube as far as you want to go (when you tap it further the inner diameter of the tube is reduced over a longer length making it a better insulator, but the strenght of the tube is reduced at the same time). 10mm deep will work.

Now cut of the part of the tube that you didn't drill out, you probably know by now why to keep it longer till this point ;)

The stainless steel tube will be lined on the inside with a PTFE tube to reduce friction. The 1/4(6.35mm) outer diameter PTFE won't fit in the 5.5mm inside diameter insulator. To make this fit the PTFE tube will be reduced in diameter with a M6 die.Put a 65mm long piece of PTFE tube 1/4" od (=6.35mm) in the drill, you might want to put a piece of metal in the PTFE tube to clamp it tight in the drill. Slowly drill the PTFE through the die. Thread about 40mm of the PTFE.

Assemble and clean the inside of the insulator by manually drilling it out with a 1/8" or 3.2mm drill.

How to make the hot end nozzle

Here it is shown how to make a heating tube with nozzle out of a welding tip with a inner diameter of 0.6mm. Alternatively you can make a tip out of a m6 brass bolt. The welding tips i found in Canada have a m6 thread on one end and has a smooth part of 1/4" (6.35mm) on the other end.

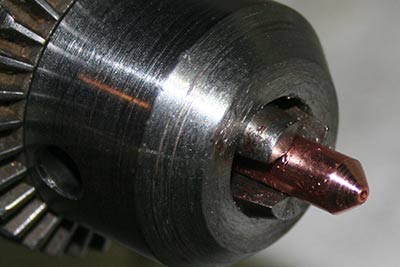

Sharpen the point of the weling tip, if you don't do this the plastic will stick to the flat side of the nozzle making ugly prints. Put the welding tip in the drill and sharpen it using a file.

Reduce the diameter of the smooth part to about 6mm so it can be threaded with M6 to attach a heater block or wire.

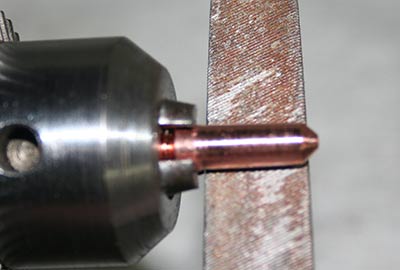

Now put m6 thread on the smooth part with a M6 die. I found it easy to clamp the drill chuck in the vice and thread it. (so leave the welding tip in the drill and clamp the drill chuck in the vice) otherwise the soft welding tip will likely get damaged in the vice.

(i did a shitty job here, i started of on an angle. No problem though)

Put some m6 nuts on the m6 thread and tighten them to each other. Put the nuts in the drill chuck and put a 1/8" (=3.2mm) drill in the vice.

Drill a hole in the welding tip to about 1-2mm from the nozzle. Use plenty of oil, go slow, make long chips. The drill will follow the 0.6mm hole in the welding tip making centering easy!

When done clean out the nozzle, make certain no dirt is left in it!

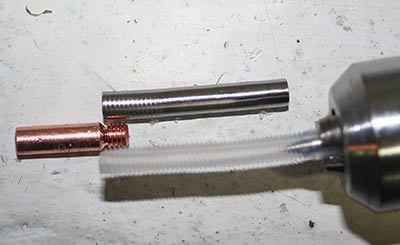

The finished insulator and heater with nozzle. (you can easily do a better job the i did ;)