Open hardware fast high resolution LASER

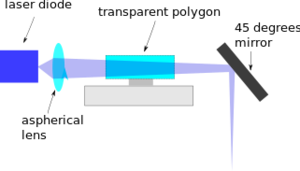

This article describes an open-hardware transparent polygon laser diode scanner suited for 3D printing. The Dutch company Hexastorm plans to sell the first open-hardware transparent polygon scanner. The machine is shown in figure 1.

Contents

Description

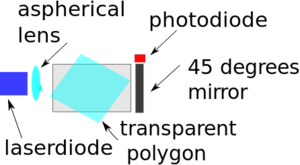

The transparent polygon scanner consists out of a laser diode which is focused directly with an aspherical lens. The bundle refracts through a transparent polygon and is directed to the surface with a 45 degrees first sided mirror. The bundle is deflected by tilting a transparent plate. The position of the laser bundle is monitored by a photo-diode. A Field Programmable Gate Array (FPGA) is used to ensure the correct timing of and stream data to the laser diode. A schematic sideview and top view of the system is shown in figure 2 and 3.

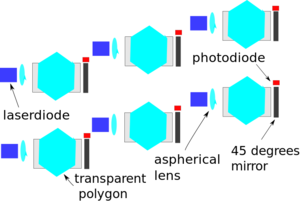

A substrate can be solidified by moving the optical head in a snakelike pattern over the substrate as shown in figure 4. The line speed is 16 to 84 mm/s. The maximum line length is 24 mm. The standard spot speed of an FFF printer is 50-80 millimeter per second. The Hexastorm is able to reach a spot speed of 67 to 350 meter per seconds. The smallest element of an FFF printer is the nozzle which is a circle with a 300 micrometers diameter. In the Hexastorm, this is an elliptical laser spot which is 50 by 60 micrometers. The transparent polygon scanner therefore represents a revolution in open-hardware 3D printing technologies. The system has four advantages; it provides a high optical quality, it is cost effective and it is scalable for industrial applications. The system has a high optical quality as the bundle is in focus over the full scan line and is incident at 90 degrees. The transparent polygon scanner therefore gives a flat field projection and the system is telecentric. The system is cost effective as it is able to do this without an expensive f-theta lens. Only two optical elements are needed; an aspherical lens and a transparent polygon. A reflective polygon scanner needs a thick disk as collimated bundles with a larger diameter can be focused too smaller spots. In the transparent polygon scanner shown, the laser is focused before it hits the polygon. As a result, the disk can be made thinner and therewith lighter and as a result the polygon is easy to spin and balance. Finally, the system is scalable. The maximum optical power of laser diodes becomes less as their wavelength becomes shorter. As a result, laser diodes need to be combined to give more power. It is, however, not possible to combine more than two lasers into bundle without interference. The electromagnetic field can only have up to two polarizations. Companies like Kleo Halbleitertechnik therefore also sell systems which use 288 laserbundles. Companies like Hexastorm can achieve a 600 mm illumination width with 80 bundles. Hexastorm has an advantage as it uses one polygon per bundle. Kleo uses multiple bundles per polygon and therefore has a scan angle of 45 degrees or less. The concept of scan angle is explained in the physics section.

Search Report

There are several other polygon scanners used to combine the power of multiple laser diodes. KLEO Halbleitertechnik, which was partly owned by Zeiss and later sold to Manz, sells the Speedlight 2D. The Speedlight 2D is a system which uses 9 polygons and 288 laser diodes to solidify a substrate with a width of 650 mm. The reflective polygon has 32 facets and rotates at a speed of 50.000 rotations per minute, see patent US8314921B2. The Netherlands Organization for Applied Scientific Research (TNO) developed a system which is similar to that of Kleo AG but which uses a transparent instead of a reflective polygon, for details see patent application WO 2015/160252 A1. The transparent polygon scanner proposed in this article is different from TNO in that it uses a single and not multiple optical bundles per transparent polygon. In addition, the rotation axes of the the proposed system are orthogonal and not co-planar with the substrate. The first polygon scanner in additive manufacturing was used by the Institute of Physical and Chemical Research (RIKEN) in 1997. In 2013, Envisiontec filed a patent US20130001834 A1 for a reflective polygon scanner in additive manufacturing to protect its Scan, Spin and Selective Photocure (3SP) technology. Other patents of relevance are; US6897888B2 (interleaving of scan patterns), US6731320B1 (varying the duration of pixels to compensate for scan velocity variations). This might be mitigated by shifting information to other pixel and not extending or shrinking pixels in time. Older transparent polygon scanners are; US5216534 (Read-write head for an optical tape recorder), US5815242A (Wide field scanning opthamoscope), US5428467 (Transmissive polygonal optical scanning of illumination for light valve video projector) and EP1424598 (Lithographic projection apparatus and device manufacturing method).

Business Case

Competitor Analysis

The large area photo-polymerization market and printed circuit board (PCB) market are seen as the commercially most interesting markets. High end large area photo-polymerization machines or PCB machines tend to be closed source. Wohler's report defines industrial machines as those with a sales price over 5000 dollars. In the order of 13000 systems are sold per year. The photo-polymer market has market cap of 300 million dollars. The year on year growth is in the order of 30 percent. More detail can be found in Wohler's Report. In the photo-polymerization market competing machines are the PromakerL7000D (Prodways), ProX 950 (3D Systems) and XEDE 3SP(Envisiontec). Formlabs has been omitted as it uses a collimated bundle, i.e. the laser diode is not focused. The number of pixels offered by DMD printers like the Rapidshape or Carbon 3D is seen to be too small even with a 4K DMD. In the PCB market competing machines are the Nuvogo Fine 10 (Orbotech), Speedlight 2D (Manz) and the Ledia 3WL (Ucamco). The resolution requirements of the PCB markets and additive manufacturing (AM) are estimated at 15 micrometers and 50 micrometers respectively. It is therefore thought that market entry can best be achieved via the AM market and later the PCB market.

Alternative Exposure Technologies

The following alternative illumination technologies can be distinguished;

- Polygon scanner with refractive F-theta lens and one laser bundle

- Used by: Envisiontec, Orbotech

- Notes: Three element F-theta lenses are expensive, telecentric systems are even more expensive and can, unlike transparent polygon scanner, not project outside the lens. For high-resolution systems, it can be beneficial to use a thick polygon, for a supplier see Lincoln Laser. An example calculation is given here. Transparent polygons can be thinner as the bundle is already focused.

- Polygon scanner with reflective F-theta lens and one laser bundle

- Used by: Next Scan Technology

- Notes: The f-theta lens is made with reflective instead of refractive optics. This probably makes the lens lighter than a glass alternative. It might also be beneficial to use this at low wavelengths due to absorption. The system is not able to combine more than one bundle in one scan.

- Reflective polygon scanner with multiple laser bundles

- Used by: Manz

- Notes: the polygon tilt angle is smaller than 45 degrees, most likely costs 1 million euro's

- Transparent polygon scanner with multiple laser bundles

- Used by: LDI Systems (defunct)

- Notes: telecentric projection, system can project telecentric outside the lens, polygon tilt angle can be 45 degrees. The tool was at best proof of concept, light engine is thought to be in the the order of 1K euro's per mm of projection.

- DMD chip illuminated with LEDs

- Used by: Ucamco and Prodways Moving

- Notes: PCBs can be illuminated with multiple wavelengths which can be advantageous for PCB manufacturing. Ucamco uses multiple beamers adjacent to each other. Multiple beamers can be placed adjacent to each other but this expensive, as a result Prodways translates the beamer and illuminates a 45 degrees mirror, see Moving Light technology. If the mirror is illuminated with laser diodes this can result into multiple-slit interference.

- Galvanometer scanner with Nd:YAG LASER

- Used by: 3D Systems, Materialise

- Notes: low power and frequency of Nd:YAG laser, due to inertia galvanometer scanners are slower than polygon scanners

- Resonant Galvanometer Scanner

- Liquid Crystal Display (MSLA Technology)

- Used by: Structo

- Notes: Structo uses an array light source and projects through a digital mask. This technology can be scaled. It is, however, very energy inefficient see technical details. Cooling is a challenge. The technology cannot reach low wavelengths, i.e. below 400 nm. The light engine has to be in close vicinity of the reservoir. This could be an advantage for a Continous Liquid Interface Processing (CLIP) like technology.

The Grating Light Valve, sold by companies like Silicon Light Machines, can be used for mask-less lithography below 15 micrometers, for 2.5 micrometer features and was omitted. Too few applications of the MEMS scanner developed by Fraunhofer were known to take it into consideration. The femtosecond laser, which can be used in two-photon polymerization to focus light in space and time and trigger a non-linear reaction, was thought be too expensive for large-area photo-polymerization.

Alternative Light Sources

The following light sources have been considered;

- Light-Emitting Diode (LED)

- Used by: Ucamco and Prodways

- Wavelengths: 405, 395, 385, 374, 365

- Frequency: set by other element in the optical path, e.g. the refresh rate of the DMD chip

- Power:<4 watt

- Price: 5 euro's per LED

- Note: LEDs offer less contrast and depth of field than laser diodes but can be combined as they do not produce coherent light. Texas Instrument seems to have a monopoly on DMD chips. Projection systems are sold by other vendors; for example, the LUXBEAM Lithography System sold by Visitech or Wintechdigital 2.5 Watts, 405 nm, 90 micrometers, 1080p, for 4500 euro's. DMD chips can handle less optical power at shorter wavelengths. For wavelengths below 405 nm, the power limit is currently 4 W per chip DLP9000UV.

- Laser Diode (LD)

- Used by: Manz, Envisiontec

- Wavelengths: 405, 395, 375 nm

- Frequency: 50 MHZ

- Price: 40 euro's at 405 nm, 3870 euro's at 375 nm

- Power: 0.4 W at 405 nm, 70 mW at 375 nm

- Cooling: SLD3237VF can operate at 80 degrees.

- Diode-Pumped Solid State Laser (DPSSL)

- Used by: Orbotech

- Wavelength: 355 nm

- Frequency: 80 MHZ

- Power: 24 W

- Price: 190k euro's (only laser, you also need a chiller and a power supply)

- Vendor: Coherent

- Sizes: LASER 305 x 200 x 1100 mm, power supply 482 x 177 x 505 mm,

- Nd:YAG LASER

- Used by: 3D systems and Materialise

- Wavelength: 355 nm

- Power: 1 W

- Frequency: < 1MHZ

Proof of Concept

The goal of this project is to build a transparent polygon scanner. At 20-12-2016, it was shown that it is possible to mount a transparent disk on top of a polygon motor and spin it it at 21000 RPM.

Bill of Materials

- Quartz optical window, 2 mm thick, square cross-section of 35x35 mm, 150 dollars

- Ricoh Aficio AF-1027/270, 20 dollars (also used in the OpenExposer)

- iC-HG 200 MHz Laser Switch development board, 60 dollars (IChaus)

- PIN photodiode with blue enhanced sensitivity, BPW 34 B (Osram)

- FPGA: XuLa 2-LX25, 119.00 dollars with StickIt! v-4, 19.95 dollars

- Computer: Raspberry 3, 16GB SDHC, 1 meter network cable, housing, 2A microusb power, 62 dollars

- Software: Ubuntu 16.04, Python 3.5 (libraries: FPGA Myhdl, Spot Detection OpenCV, Slicer VTK)

- CCD camera; open

- Grey Filter

- Protective glasses

Physics

In the following, an analytical description of the system is given. The section starts with a parameter definition. Hereafter, the following properties are discussed; polygon, spot and transparent parallel plate and air bearing.

Parameter Definition

The polygon rotates about its center, i.e. the point inside the polygon that is equidistant from each vertex. The substrate moves under the polygon in a certain direction. The smallest angle between the illumination direction and the substrate movement direction is defined as the polygonal tilt angle.

- <math>\alpha</math> denotes the static polygonal tilt angle. In the proposed system, this is 90 degrees.

- <math>\alpha^'</math> denotes the polygonal while scanning (the polygon tilt angle is speed dependent)

- <math>I</math> is the angle of incidence of the optical beam on the transparent polygon

- <math>I_{max}</math> is the maximum angle of incidence used during illumination

- <math>f_{efl}</math> is the effective focal length of the lens used to focus the bundle

- T defines the thickness of the polygon, T is equal to 2r.

- r defines the inradius of the polygon

- a defines the polygon side length

- R defines the circumradius of the polygon

- v is the number of vertices of the polygon.

- n is the refractive index of the polygon, quartz is used with a refractive index of 1.47

- d is the diameter of the aspherical lens

- <math>\lambda</math> defines the center wavelength of the laser diode beam

Polygon

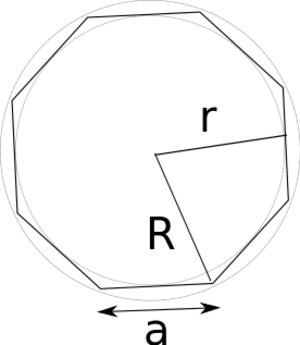

In figure 5, a regular convex polygon is shown with the following parameters; r is the inradius, R is the polygon circumradius and a is the polygon side length. In figure 5, the number of vertices, v, is equal to 8. Earlier, we defined 2r to be equal to T. The number of facets of the polygon has to be even for opposing planes to be parallel. If the number of facets is uneven, there will be an edge crossing during illumination which makes it unsuited for scanning.

- <math>a=T\cdot tan(\pi/v)</math>

- <math>R=\dfrac{a}{2 \cdot sin(\pi/v)}</math>

- The interior angle of a simple polygon with v vertices is <math>180-360/v</math> degrees.

For an octagon, <math>I_{max}</math> cannot be larger than 67.5 degrees.

Spot

Light emerges from a small optical window from the laserdiode and as a result diverges. There are several ways to focus the diverging beam. The choice is a trade-off between spot quality and cost. Two possibilities are discussed; (1) an aspherical lens and (2) with achromatic doublet after collimation with an aspherical lens and circulation with an anamorphic prism pair.

Lens Alignment

The lens alignment is determined by the optical magnification of the whole system. The emission point typicaly has a size of 0.5 micrometers by 1 micrometers. The size can be measured via the Fraunhofer diffraction pattern. The emission point accuracy is assumed to be +/- 80 micrometers. This was estimated from similar laser diodes. For a 50 micrometers spot, the aspheric lens has to be placed at an accuracy of 3 micrometers (simulation should be added). The magnification is 50. The aspheric lens can be purchased mounted with a M9 thread and screwed into position with a screw driver.

Rayleigh length

The spot is defined to be in focus in twice the Rayleigh length; <math>z_r=\dfrac{2 \pi w_0^2}{M^2 \lambda}</math>. <math>M^2</math> is called the beam quality factor. Most collimated single TE mode laser diode beams have <math>M^2</math> of 1.1 to 1.2, source Sun, Haiyin.

Spot size

The spot size of a collimated and circulated bundle focused by an achromatic doublet is <math>w_0=\dfrac{4\lambda}{\pi}\dfrac{f_{efl}}{D}</math>, where D is the diameter of the collimated bundle. The spot distance is <math>f_{efl}</math> from the achromatic doublet.

The spot distance of a laserdiode directly projected by an aspheric lens is given by the thin lens equation; <math>\dfrac{1}{f_{efl}}=\dfrac{1}{s_1}+\dfrac{1}{s_2}</math>. <math>S_1</math> denotes the distance between the laser diode and the aspheric lens. <math>S_2</math> denotes the separation between the aspheric lens and the spot. The magnification, M, is given by <math>M=-\dfrac{s_2}{s_1}=\dfrac{f}{f-s_1}</math>. As the emission point is not square, the spot will be elliptical.

The smallest spot which can be formed is given by the Airy disk. <math>w_0 \approx 1.22\dfrac{s_2 \lambda}{D}</math>. Here D is the width of the collimated beam or divergent beam at the lens.

Transparent Parallel Plate

The properties of a parallel plate are described by Smith and Wyant. The most important properties of a parallel plate are summarized in this section. Typically, a parallel plate is used to transversely shift a collimated bundle. For a converging beam, a parallel plate also gives a longitudinal focus point displacement towards the source and optical aberrations. The optical aberrations increase if I is increased. Via an analytical calculation it is ensured that the Strehl ratio is above the Rayleigh limit at <math>I_{max}</math>.

Displacement

- longitudinal displacement <math>=\dfrac{n-1}{n}T</math>

- transversal displacement <math>=T sin I(1-\sqrt{\dfrac{1-sin^2 I}{n^2-sin^2 I}})</math>

- The spot speed can be derived by differentiation the transversal displacement with respect to I. The speed at the center is smaller than the speed at the edges of a projected line. As a result, the amplitude at the center should be smaller and is ideally corrected for by the laser diode driver by varying the pulse frequency or current.

Seidel Aberrations

The f-number or <math>f_\#</math> equals <math>\dfrac{f_{efl}}{D}</math>. A transparent plate does not have a Petzval field curvature aberration. As a result, the projection of the transparent polygon is telecentric. The other aberrations are:

- spherical wavefront abberation <math>=-\dfrac{T}{f_\#^4}\dfrac{n^2-1}{128n^3}</math>

- coma <math>=-\dfrac{TU}{f_\#^3}\dfrac{n^2-1}{16n^3}cos\theta</math>

- astigmatism <math>=-\dfrac{TU}{f_\#^2}\dfrac{n^2-1}{8n^2}cos^2\theta</math>

The wavefront aberrations can be used to calculate the Strehl ratio. If the Strehl ratio gets below a limit during illumination, the aberrations will become dominant and the system will not image properly. As a result, it must be ensured via calculation that the Strehl ratio is larger than some acceptable limit, e.g. the Rayleigh limit of 0.71. Systems with a spot size close to 10 micrometers are possible. The main challenge is the placement of the optical components.

Air Bearing

Air bearings fly on a thin film of air between the shaft and the sleeve. The motor must quickly accelerate to flying speed which, typically, is above 8000 rpm, source. Air bearings wear upon startup and can typically last up to 20K-100K start stop cycles. A polygon spinning at high speeds will resist any tilting motion of the scanner. The spinning polygon acts like a gyroscope. Air bearing scanners are therefore limited to static applications and low mirror weights. In practice, the polygon can be moved if it is well balanced. An unbalanced polygon is harder to move. The balancing procedure for transparent polygons is similar to that of quad copters, see YouTube Video.

Simulation

The calculation can be verified with an open optical ray tracing and lens design framework, such as the Python library made by Dr. Jordens named Rayopt.