Prusa Mendel/fr

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: fonctionne

| Description | Prusa Mendel une adpatation simplifiée de la Mendel.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

- If you are building this machine using SAE (imperial) fasteners, see also SAE Prusa Mendel.

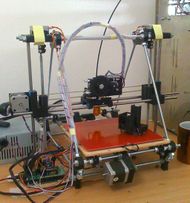

Prusa Mendel is the Ford Model T of 3D printers.

Like the Model T, the Prusa Mendel improves on a previous design by being more streamlined for manufacture. The Prusa Mendel is a simpler remix of the original Mendel. By default, it uses printed bushings instead of regular bearings, though options to substitute inexpensive lm8uu linear bearings or other types of bearings or bushings are available. The current version uses three 608 bearings in total, one for the X axis and two for the Y axis. The 624 bearings are gone altogether.

Prusa's main goal is to be the purest and simplest 3D printer you can build.

- It's much simpler to build it.

- It's much simpler to modify it.

- It's much simpler to print it for your friends.

- It's much simpler to repair it.

Because of its complexity, the Prusa Mendel can be a living thing. I update it all the time. It's a unique feature but it should be standard. We are living in feature, we don't care if it's a bit different every time; our printer will print it in same time ;-)

Contents

<videoflash>tyVM3-v84I0</videoflash>

Développement

Le développement de la Prusa Mendel est hébergé sur github: http://github.com/prusajr/PrusaMendel.

Vous pouvez suivre les évolutions là: Changelog.

Vous pouvez vous inscrire gratuitement sur github, créer une nouvelle branche et travailler dessus.

Historique

liste de pièces

Pièces imprimées

Pièces non imprimées ("les Vitamines")

Notez que l'extruder requière d'autres pièces, bien que certaines soient inclues dans la table ci-dessous.

| Quantité | Description | Type | Commentaires |

|---|---|---|---|

| 83 | M8 écrou hexagonal | attache | Acheter un paquet de 100 pour être tranquille. |

| 93 | M8 rondelle | attache | Acheter un paquet de 100 pour être tranquille. |

| 6 | M8×30 Rondelle de diametre ext 30 | attache | |

| 2 | M4×20 boulon, Vis Chc | attache | Pour fixer l' Extrudeur |

| 2 | M4 écrou | attache | Pour fixer l' Extrudeur |

| 2 | M4 rondelle | attache | Pour fixer l' Extrudeur |

| 22 | M3×10 boulon | attache | |

| 16 | M3×25 boulon | attache | Or eight M3×25 boulon plus eight M3x20 boulons. Les boulons M3x25 sont trop longs pour le récent support de moteur z Prusa, la pince à tige, et aussi pour le couplage des moteurs Z. Voir détails: Section 8, étapes 4 et 13. |

| 4 | M3×40 boulon | attache | |

| 70 | M3 rondelle | attache | |

| 40 | M3 écrou | attache | 8 optionally locknut / stop nut / nyloc |

| 2 | M3 vis sans tête empreinte btr | attache | Les vis de type M3x8 semblent idéales (il faut une longueur minimale de 6mm, du M"x10 convient également). |

| 3 | roulement de type 608 | roulements | destinés aux rolleurs / rollers en ligne / skateboard |

| 4 | ressort de stylo à bille | ressort | Pour aller sur des boulons M3. Les stylos à bille sont très communs, une source peu chère de ressorts qui font l'affaire. Ils sont longs d'environ 25mm et se compressent jusqu'à 10mm. |

| 6 | M8×370mm | tige filetée | 3 de chaque coté Note: Les tiges filetées peuvent être coupées dans des pièces plus longues 6x1m (voir 'ordre de découpage des tiges filetées' plus bas). |

| 4 | M8×294mm | tige filetée | devant / derrière |

| 3 | M8×440mm | tige filetée | haut / bas |

| 2 | M8×210mm | tige filetée | pas de vis en Z |

| 1 | M8×50mm | tige filetée | or M8x30 or longer boulon for X idler. Take care: if the boulon is too long, it may not be threaded along a sufficient length |

| 2 | 8mm×420mm | tige lisse | X-bar Note: 304 Stainless Steel or A2 Tool Steel are recommended for tiges lisses as it can help to prevent friction from rust and manufacturing (straightness) standards are higher. Rust issues can be prevented on the normal steel rods by maintaining a coat of oil. The tiges lisses can also be cut from larger 3x1m pieces (see Ordre de découpage des tiges lisses plus bas). |

| 2 | 8mm×406mm | tige lisse | Y-bar |

| 2 | 8mm×350mm | tige lisse | Z-bar |

| 1 | 225mm×225mm plaque | Plaque | plaque du dessus |

| 1 | 140mm×225mm plaque | plaque | plaque du dessous |

| 1 | 840mm×5mm T5 courroie dentée | courroie | pour l'axe Y |

| 1 | 900mm×5mm T5 courroie dentée | courroie | pour l'axe X |

| 5 | NEMA 17 bipolar stepper motor | Stepper | Be sure to get ones with at least 20mm of shaft length. Shorter shafts require modifications to the X pulley assembly and Z motor couplers. One of the five motors, for use with the extruder, should be capable of creating a holding torque of at least 40Ncm, at the very least. |

| 50 | small cable binder / ziptie | Misc | |

| 1 | Wade's Geared Extruder | for 1.75mm filament RepRap Universal Mini Extruder; or any other compatible extruder for either | |

| 1 | Electronics + endstops | This can be RAMPS, Sanguinololu, Gen6, Gen7, Gen3, or any other Mendel compatible electronics. Endstops are either optical switches or microswitches (Recommended), and you need three, one for each of the X, Y, Z axes. |

| Quantity | Description | Type | Comments |

|---|---|---|---|

| 3 | 30mm×10mm Optoflags | Thin Sheet | if using opto endstops |

| 2 | 8mm ID ressort | ressort | to eliminate backlash in the z axis |

| 1 | object with precisely 290mm length | for frame alignment | |

| 1 | object with precisely 234mm length | for frame alignment |

Note: You can combine the latter two by having a piece of thick sheet with dimensions 290mm×234mm. Make sure to mark which side is which.

ordre de découpage des tiges filetées (A partir de pièces de 1m de long):

Required: 6x1m Long 8mm tiges filetées (or 5x1m pieces + 1x50cm piece) Rod 1: 370mm, 370mm, 210mm, ~50mm (The last piece will end up somewhat shorter than 50mm. ) Rod 2: 370mm, 370mm, 210mm, ~50mm ( Use it for your idler. Alternatively, an M8x30 or ) Rod 3: 370mm, 294mm, 294mm, ~42mm ( longer boulon can be used. ) Rod 4: 370mm, 294mm, 294mm, ~42mm Rod 5: 440mm, 440mm, ~120mm Rod 6: 440mm

Ordre de découpage des tiges lisses (when cutting from 1m lengths):

Required: 3x1m Long 8mm Smooth Stainless Steel Rod Rod 1: 420mm, 420mm Rod 2: 406mm, 406mm Rod 3: 350mm, 350mm

The Prusa Mendel uses the 4 drivers in the standard Mendel electronics package to drive 5 motors by using two steppers wired in parallel to one driver [1].

Where To Purchase

See the Mendel Buyers Guide for information on where to purchase all of the parts needed.

See the Prusa Buyers Guide for information on where to purchase all of the parts needed.

Printing the Parts

Printing a Prusa on a Mendel

The pre-assembled build file is an easier option for printing Prusa parts from a RepRap Mendel. With this option you only need to print mendelplate.stl and pla-bushing.stl to get a complete set of printed parts for the Prusa Mendel:

- Mendel Plate (contains all printed parts except the PLA Bushings)

- PLA Bushing

Printing a Prusa on a CupCake CNC

There are also pre-assembled build files available to fit your CupCake CNC's build area (download using right click => save as)

Note:

- These plates are 85x95mm in size and require a total of ~1 lb (~ 450 g) of plastic to print.

Plates for the MakerBot (the plates have changed, these print times are no longer accurate):

- Makerbot Plate 1=> 6 hrs 30 min

- Makerbot Plate 2=> ~2 hrs 30 min (needs retesting)

- Makerbot Plate 3=> 5 hrs 40 min

- Makerbot Plate 4=> 2 hrs 30 min

- Makerbot Plate 5 => 1 hr 50 min

Printing a Prusa on anything else

Last but not least, if you have a machine that doesn't fit into any of the previous options all the .stl files necessary to print a Prusa Mendel are available on the PrusaMendel Github where you can download them and print them individually.

Buy the printed parts

Mendel_Buyers_Guide#RepRapped_Parts_Kits

Assembly

- Assembly instructions >> Prusa Mendel Assembly.

- Required Tools

Media

- Two printers simultaneously - Prusa and shaper cube working side by side.

- Prusa homing using endstops

- Prusa development overview

- Prusa Y axis stress test

- Prusa Z axis stress test

- Early preview of the Prusa Mendel redesign

- Fumon's Prusa build session 1 - D1plo1d building Fumon's Prusa Mendel at Hacklab.to. Should give a hint as to how the Prusa Mendel parts go together.

Prusa Improvements/Hacks

- Rob's Auto-centering shaft coupler - designed to reduce shaft/motor vibrations (print 2/replaces 2x coupler). May require widening the openings on the z motor mounts to allow the rotation of the zip tie. Use a zip tie gun to get maximum compression on the coupling.

See Also

- Prusa's Blog

- Prusa Builder Blog Feed

- Assembly photo gallery

- Prusa Mendel Visual Instructions - A nicely formatted version of the assembly process in PDF.

- Paperback version the Prusa Mendel Visual Instructions, also available in color.

- Prusa Mendel Assembly Video Tutorial This video, the first of a series, provides an overview.

- RichRap Blog - Prusa Mendel Bling - Pimp my Mendel - How to build up a LM8UU Linear Bearing Prusa

- Latest Aleph Objects/LulzBot Bill of Materials

- Longboat Prusa LM8UU based Prusa with build instructions.