Prusa i3

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: working

| Description | Prusa i3 is a design by Josef Prusa.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

The Prusa i3 (iteration 3) precedes a third iteration (i3) MK2 which can be found here: Prusa i3 MK2. The i3 incorporates lessons learned from the previous two Prusa designs, as well as other popular modern RepRap designs. See also Prusa Mendel (iteration 2).

| |

Derivates The Prusa i3 is a very popular design, which led to many people creating derivates. We list these derivates in Category: Prusa i3 Derivate. Also check the Prusa i3 Variants page, as well as the Prusa i3 Development page |

Contents

Specifications

| Single Sheet Frame | Box Frame | |

|---|---|---|

| Plastic Parts (exc. Extruder) | 26 | 29 |

| Non Printed Parts (approx.) | 337 | 293 |

| Cost (USD) | $300-1000 | $300-$800 |

| Controller Electronics | Almost all RepRap | Almost all RepRap |

| Printing Size (mm) | 200 x 200 x 200 | 200 x 200 x 270 |

| Motors | 5 x NEMA 17 Stepper | 5 x NEMA 17 Stepper |

| Frame Material | 6mm Aluminium, Wood | 12mm Wood |

| Frame Manufacture | Laser Cutter, CNC, Water Jet | Basic Woodwork Tools |

| Pro | Easy assembly | Rigid XZ to Y Connection |

| Con | Specialised Tools | Looks less professional? |

Main improvements

The following is a list of the main improvements made upon the Prusa Mendel Iteration 2

- Enhanced frame rigidity (prevents x-axis backlash)

- Easy assembly

- Parametric files for multiple sizes/bearings or bushings

Development

The development of the Prusa Mendel is hosted on github: https://github.com/josefprusa/Prusa3.

History

Prusa i2 (November 2011)

On 11-11-11, the Prusa i2 is announced on the reprap blog.

Prusa i3 (May 2012)

The first commit to the Prusa3 GitHub repository.

"Final refactoring complete" (September 3 2012)

Josef Prusa: "Final refactoring complete."

There were many commits the following months, evidencing the continuous development process.

The rate of commits dropped rapidly after August 2013.

However, that is not the end of the Prusa i3 development. See the Prusa i3 Development page here.

Original development moved to Vanilla (January 2014)

Prusa moved the original development to "vanilla repository" on Github in January of 2014.

Offical kit available (May 2015)

In May 2015, the official kit became available from Prusa.

Variants

Main article: Prusa i3 Variants

The release of the Prusa i3 under the GPL license and numerous other factors (its low cost, minimal BOM, simple assembly and calibration procedures, more than adequate documentation, etc) have encouraged the further development of a growing number of Prusa i3 "variants" worldwide, with different parts, different materials and different assembly processes, but which altogether adhere to the general looks, component assembly, dimensions and functionality of the original Prusa i3.

See the page Prusa_i3_Variants for an attempt to list the Prusa i3 Open Source variants along with their differences / improvements and "genetic lineage". Also check out the Category: Prusa i3 Derivate page which lists using the wiki tagging feature.

Printed Parts

OpenSCAD files for the printed parts are available on the Github repository.

To compile the parts and render STL files, copy configuration.scad.dist[1] to configuration.scad, and customize by editing values.

Precompiled STL files to make the printer can be found at the Clone Wars page for the i3, and here zipped up: File:Clonewars.zip.[1]

Frame type

Most major Prusa i3 Frame Styles fall into two categories: the Single Sheet Frame, and the Box Style Frame.

The Single Sheet Frame is designed to be manufactured through the use of a Laser cutter, WaterJet, or CNC Mill / Router Table. There are two current development tracks within the Single Sheet Frame, an Aluminium frame style, and a gusseted Wood frame style. Both are designed to support 6mm or thicker framing material. Both the EiNSTeiN variant and the i3 Rework designs use single sheet aluminum frames, as do most kits. The Box Style Frame, on the other hand, is designed to be easily manufactured at home with basic woodworking tools. The Y-axis for both frame styles is similar to that of the older Prusa Mendel Iteration 2.

Single Sheet Frame

This is a frame created from flat metal sheet, typically Aluminium, but can also be made from other material with a thickness usually between 3mm (0.125 inch) and 6mm (0.25 inch).

Pro:

- Looks professional (subjective).

Con:

- Requires specialized tools (e.g. abrasive water jet cutter, laser cutter, CNC router) or contracting out.

- Less rigid connection between XZ-frame and Y-frame part.

Box Style Frame

This frame is created from 8 small sheets of wood.

Pro:

- Can be created with standard DIY tools.

- More rigid connection between XZ–frame and Y–frame part part.

Con:

- Looks less professional (subjective)

Electronics

Stepper Motors

The Prusa i3 uses, including the extruder, 5 NEMA17 stepper motors. Two of these motors, the Z axis motors, are connected to the same stepper driver of the electronics. If using Wade's Extruder, its stepper motor needs a minimum holding torque of 40Ncm (0.4Nm). More information can be found on the Stepper Motor page.

Controller Electronics

About any RepRap controller works for the Prusa i3. Required features: 4 stepper drivers, 1 thermistor input and 1 heater output for the extruder and optionally another thermistor/heater pair for the heated bed. Choosing the best one for your printer is mostly a matter of taste. For comparisons, see List of electronics, Comparison of Electronics and Alternative Electronics.

Extruder

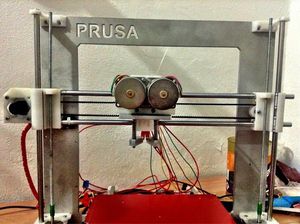

On November 12th, 2012 Josef Prusa (@josefprusa) tweeted a picture of his metal frame i3 with a custom dual extruder mounted.

Previous posts on Prusa's twitter feed reveal that Sound (Slic3r's Developer) inspired Prusa to attach a dual extruder.

In may 2015 was published the &makers single direct drive extruder named &struder, was designed to use on Wood multitool and now is adapted to use on prusa i3.

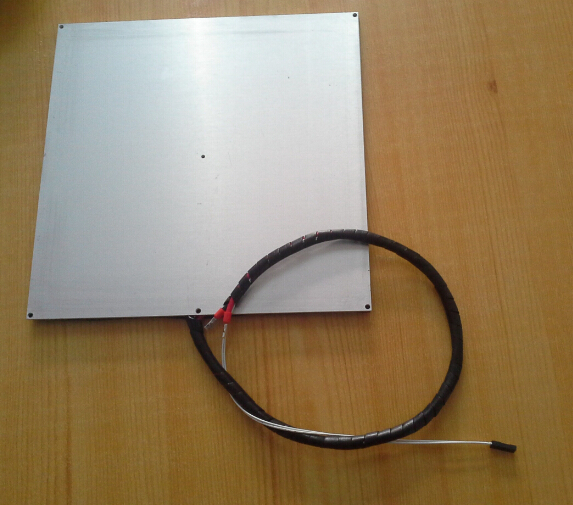

Heated Bed

The Prusa i3 includes a Heated Bed which allows for the use of materials such as ABS and nylon which can experience significant warping if printing on a cold platform.

- MK3 heating bed, aluminum plate thickness of 3 mm, uniform heating, fast, back has good heat preservation, high temperature can be heated to 120 degrees

Filament Holder

For Sheet Style,

- http://www.thingiverse.com/thing:60720

- http://www.thingiverse.com/thing:68329

- http://www.thingiverse.com/thing:153792

For Box Style,

- http://www.thingiverse.com/thing:104557,but I recommend using threaded rod and bearings with this thing, like this

- http://www.thingiverse.com/thing:111157

- Top rated mountain hunting boots

Videos

- Mini Prusa i3 Aluminum (English) Detailed HD Assembly Videos on Youtube (engineglue)

- Montando la Prusa Mendel i3 (Spanish) http://www.youtube.com/watch?v=-31Zn7wY7jk

- Aluminium Body i3 (Spanish) Video montaje completo por capítulos (OverCraft3D)

Notes

- ↑ Please note that the zipped files are not compatible with holes for the Z axis brackets in the Prusa3ALU-*.dxf drawings, at least the ones in the old/ folder in github. Also, the models for Y-axis brackets are for M8 rods. Compiling your own and investigating the Prusa github packages is highly recommended!