Prusa i3/ja

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: working

| Description | Prusa i3 is a redesign by Prusajr.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

イントロ

The Prusa i3 (iteration 3) is the newest and current 3D Printer design by RepRap Core Developer Prusajr. The i3 incorporates lessons learned from the previous two Prusa designs, as well as other popular modern RepRap designs. See also Prusa Mendel (iteration 2). Or Graber i3 all parts in MDF (cheaper).

諸元

| ' | 単板フレーム | 箱形フレーム |

| プラパーツ (exc. Extruder) | 26 | 29 |

| 非プリントパーツ数 approx. | 337 | 293 |

| コスト | $300-1000? | $300-$800? |

| コントローラ | Almost all RepRap | Almost all RepRap |

| プリント可能サイズ | 200 x 200 x 200 | 200 x 200 x 270 |

| モータ | 5 x NEMA 17 Stepper | 5 x NEMA 17 Stepper |

| フレーム材質 | 6mm Aluminium, Wood | 12mm Wood |

| フレーム作成方法 | Laser Cutter, CNC, Water Jet | Basic Woodwork Tools |

| 利点 | Easy assembly | Rigid XZ to Y Connection |

| 欠点 | Specialised Tools | Looks less professional? |

変更点

以下はPrusa Mendel i2からの変更点

- フレーム剛性強化(x軸のバックラッシュ改善)

- 製作の簡易化

- 異なるサイズ・ベアリング・軸受に対するパラメータファイル

開発

Prusa Mendelの開発についてはこのgithubで

履歴

プリントパーツ

このプリンタの構成部品のSTLファイルはClone_wars:_Prusa_iteración_3にある(zipファイルFile:Clonewars.zip)。 但し、zipファイル版のPrusa3ALU-*.dxfにはz軸ブラケットの互換性がありません。さらにy軸ブラケットはM8仕様になっています。 Purusaの設計図を独自に編集・研究することが望ましい。

独自に編集するならば、Github [[2]](箱形)か[[3]](単板)からファイルを持ってきて、configuration.scad.distをconfiguration.scadにコピーして編集する。

一度はこのディレクトリ内の.scadファイル(complete-printer以外)をRPすべし(RPの意味がわかりません、誰か翻訳よろしく)。このプリンタは0.3mm厚と2.2押し出し幅(厚/幅)似たいし0.66mmストローク幅に設定されています。

画像の参考としてdoc/complete-printer.scad、ガイドとしてdoc/manual.txtが使えます。

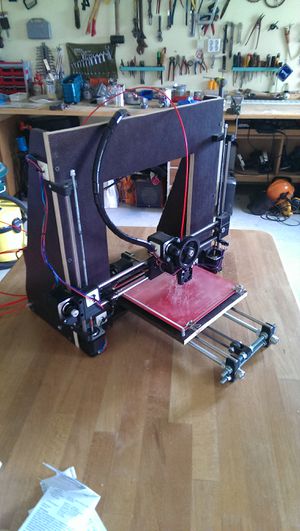

フレーム型

Prusa i3のフレームは箱形と単板型の2種類に分かれる。単板型はレーザカッターやウォータジェット、CNCで造られる。 There are two current development tracks within the Single Sheet Frame, an Aluminium frame style, and a gusseted Wood frame style. Both are designed to support 6mm or thicker framing material. Both the EiNSTeiN variant and the i3 Rework designs use single sheet aluminum frames, as do most kits. The Box Style Frame, on the other hand, is designed to be easily manufactured at home with basic woodworking tools. The Y-axis for both frame styles is similar to that of the older Prusa Mendel Iteration 2.

単板型

This is a frame created from a single sheet of metal, typically Aluminum, but can also be made from various Materials with a thickness greater than 6mm / 0.25 inch

利点:

- Looks professional (subjective)

欠点:

- Requires specialised tools (e.g. Water flow jet cutter)

- Less rigid connection between XZ-frame and Y-frame part, however this can be somewhat rectified by the TwelvePro variant, which provides additional frame support.

木板型

This is a version of the sheet frame that is designed to be laser cut out of wood or plastic (eg. acrylic) if you don't have access to a waterjet cutter. The only difference is that this version has support gussets on the back side of the vertical frame (the side that doesn't have the z threaded rods).

Construction is the same.

Laser cutting files can be found at github.com/sgraber/Prusa3_LC.

利点:

- Looks professional (subjective)

欠点:

- Requires specialized tools (e.g.laser cutter)

- Less rigid connection between XZ-frame and Y-frame part (Connects in the same way as the alu sheet frame)

箱型

This frame is created from 8 small sheets of wood.

利点:

- Can be created with standard DIY tools

- More rigid connection between XZ-frame and Y-frame part

欠点:

- Looks less professional (subjective)

箱型(別ver.)

This is a version of the boxed frame that uses only 5 parts instead of 8. It requires a little more work when cutting out the parts but less work to assemble.

Blueprints for the box can be found Here[4]

電装系

ステッピングモータ

The Prusa i3 uses, including the extruder, 5 NEMA17 stepper motors. Two of these motors, the Z axis motors, are connected to the same stepper driver of the electronics. If using Wade's Extruder, its stepper motor needs a minimum holding torque of 40Ncm (0.4Nm). More information can be found on the Stepper Motor page.

コントローラ

About any RepRap controller works for the Prusa i3. Required features: 4 stepper drivers, 1 thermistor input and 1 heater output for the extruder and optionally another thermistor/heater pair for the heated bed. Choosing the best one for your printer is mostly a matter of taste. For comparisons, see List of electronics, Comparison of Electronics and Alternative Electronics.

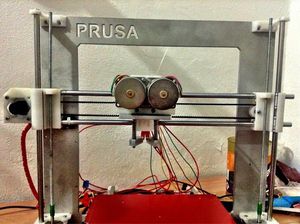

押し出し機

On November 12th, 2012 Josef Prusa (@josefprusa) tweeted a picture of his metal frame i3 with a custom dual extruder mounted.

//Need name, info, and link to this extruder and how to build it. Can anyone help? -idolcrasher

Previous posts on Prusa's twitter feed reveal that Sound (Slic3r's Developer) inspired Prusa to attach a dual extruder.

ヒータ

The Prusa i3 includes a Heated Bed which allows for the use of materials such as ABS which can experience significant warping if printing on a cold platform.

フィラメントホルダ

単板型:

- http://www.thingiverse.com/thing:60720

- http://www.thingiverse.com/thing:68329

- http://www.thingiverse.com/thing:153792

箱型:

- http://www.thingiverse.com/thing:104557,but I recommend using threaded rod and bearings with this thing, like this

- http://www.thingiverse.com/thing:111157

動画

- Montando la Prusa Mendel i3 (Spanish) http://www.youtube.com/watch?v=-31Zn7wY7jk

- Aluminium Body i3 (Spanish) Video montaje completo por capítulos (OverCraft3D)

TODO add more solutions