RepRapPro Tricolour wiring

Contents

- 1 Connections to the controller board

- 1.1 The power wires

- 1.2 The bed power wires

- 1.3 The X motor wires

- 1.4 The Y motor wires

- 1.5 The Z motor wires

- 1.6 The extruder motor wires

- 1.7 The hot-end heater resistor wires in the hot-end ribbon cable

- 1.8 Unused connector

- 1.9 The X endstop

- 1.10 The Y endstop

- 1.11 The Z endstop

- 1.12 The bed temperature wires

- 1.13 The hot-end temperature wires

- 1.14 The hot-end fan wires

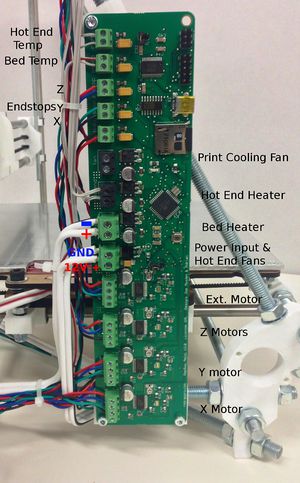

Connections to the controller board

First make sure that all the moving parts of the machine can move freely for their full travel without fouling or snagging any of the wiring. Remember that the entire X axis has to be free to move vertically.

If you have attached all the wires with tape, now is the time to go round the machine cutting off the tape (don't cut the wires...) and attaching the wires permanently with cable ties.

What you are going to do is to trim the wires to length, twist them, tin them, and attach them to the appropriate screw connector. When a wire is in its connector the insulation should abut (but not enter) the metal part of the connector. There should be no bare wire visible.

When you twist and tin the ends of the wires, put them in their connector to check the length. If any are a little long, trim them with side cutters.

When you tighten the screws in the controller board's connectors take care that

- Your screwdriver doesn't slip and damage the board,

- You don't put excessive twist stress on the board or push against it too hard - support it with your free hand.

The port marked fan is not for the extruder fan. This port is for an optional cooling fan that points directly at the print. This is useful for printing small parts and helps with detailed features when printing with PLA.

The power wires

Before you connect these, check the wires' polarity. Separate about 30mm of the end of the two power wires (don't get the bed wires by mistake).

Set your meter to read voltage. Connect the power supply into the XLR plug on the frame and plug in the mains cable, but don't turn it on.

Put the COM or Ground probe of your meter on the copper at the end of the wire with the black stripe. Put the Volts-Amps-Ohms probe on the copper in the plain wire.

Turn on the mains. Your meter should read about +12 volts. If it reads 0 or -12 volts, you have made a mistake - find it and fix it.

Turn off and disconnect the power supply.

Cut the wires to length so that they will reach the power connector on the board. The GND (black stripe) wire goes to the top of the connector and will have to be a little longer.

Bare then ends of the wires and twist them tight. Tin them. Don't use too much solder, or the result will be too fat to fit in the connector.

Screw the wires into the power connector. As mentioned the GND wire with the black stripe goes to the top, the plain wire to the bottom.

Don't do the power connector up tight - you are going to have to connect something else to the same connector in a minute.

This is the single most important electrical connection in the machine. If you get it wrong expensive bad things will happen. Take a moment to double check it.

The bed power wires

These go to the connector just above the power input connector. Again the black stripe is the low voltage one and goes to the top. The plain wire is the +12 volts wire and goes to the bottom.

Connect the wires in exactly the same way as the power wires, but do these ones up tight. Use a finger to support the back of the Melzi PCB when you are tightening screws - don't let it bend.

The X motor wires

These go to the bottom connector. From the bottom upwards the sequence is Black, Green, Blue, Red.

The Y motor wires

These go to the connector above the X motor connector. From the bottom upwards the sequence is Black, Green, Blue, Red (that is, the same as X).

The Z motor wires

These go to the connector above the Y motor connector. From the bottom upwards the sequence is Black, Green, Blue, Red (that is, the same as X).

The extruder motor wires

These go to the connector above the Z motor connector. From the bottom upwards the sequence is Black, Green, Blue, Red (that is, the same as X).

The hot-end heater resistor wires in the hot-end ribbon cable

A reminder from when you wired the hot end: the wires across the ribbon cable in order go like this:

- Heater cartridge Wire 1

- Heater cartridge Wire 1

- Thermistor

- Fan + volts

- Fan Ground

- Thermistor

- Heater cartridge Wire 2

- Heater cartridge Wire 2

The hot-end heater cartridge wires come in pairs - you will remember that you connected two to each end of the resistor to get a good current carrying capacity.

The hot-end heater cartridge wires go to the connector above the bed power wires.

Split them off from the hot-end ribbon cable, bare the ends, twist the pairs together, tin them, and fit them in the connector. The polarity doesn't matter - you can connect them either way round.

Unused connector

The connector above the hot-end heater resistor wire connector labelled "fan" is not used. Don't connect the fan to it (see below).

The X endstop

The X endstop wires connect to the connector above the unused connector. The polarity doesn't matter - you can connect them either way round.

The Y endstop

The Y endstop wires connect to the connector above the X endstop connector. The polarity doesn't matter - you can connect them either way round.

The Z endstop

The Z endstop wires connect to the connector above the Y endstop connector. The polarity doesn't matter - you can connect them either way round.

The bed temperature wires

The wires that run along with the bed power wires connect the bed's temperature-measuring thermistor. They connect to the connector above the Z endstop connector. The polarity doesn't matter - you can connect them either way round.

The hot-end temperature wires

There are two wires from the hot-end ribbon cable that connect the hot-end temperature-measuring thermistor. They connect to the connector above the bed temperature connector. The polarity doesn't matter - you can connect them either way round.

The hot-end fan wires

The hot-end fan wires in the hot-end ribbon cable do not connect to the terminals marked "fan" - those are for optional additional cooling.

The hot-end fan wires connect to the power connector in parallel with the power input so the hot-end fan is on all the time.

Make sure you get the polarity right. You should have marked the fan's + and - connections when you wired up the fan. Trace them through by counting wires across the ribbon cable.

Slacken the power wire screws and connect the fan wires in parallel with the power.

Tighten these screws firmly - this connector has to carry a large current. Remember to support the back of the circuit board when you are tightening screws to stop it bending.

Never operate your RepRap without the fan connected and running. The extruder needs the cooling at all times.