RepRapPro Tricolour x axis assembly

Introduction | Frame assembly | Y axis assembly | X axis assembly | Z axis assembly | Heated bed assembly | Extruder drive assembly | Hot end assembly | Wiring | Power supply | Commissioning | Printing | Multi‑colour/multi‑materials | Colour Printing - Slic3r | Colour Printing - RepRapPro Slicer | Maintenance | Troubleshooting | Improvements

| A notice about these instructions! |

|

These instructions are open to editing by everyone and anyone. |

Contents

Goal

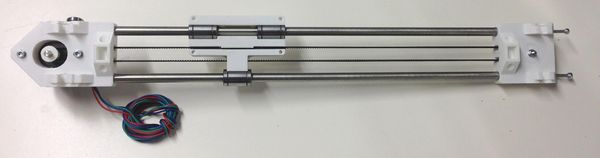

By the end of this stage, your X-axis should look like this:

Tools

You will need the following tools

- M3 Allen key

- Long-nosed pliers

- Tweezers

Step 1: X carriage assembly

The Carriage

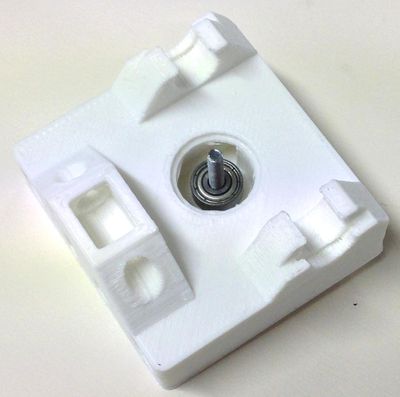

Begin by assembling the Y Idler Bracket. Take one M3x20 capscrew and a corresponding washer and insert it through the hole in the centre of the part as shown below. Then insert this assembly through the 623 idler bearing, through the cover and secure with a M3 nut and washer:

Next insert two M3 washers into the slots on the back of the idler bracket. These are intentionally a tight fit, so you may need to use a long-nosed pliers in order to grip them. The nuts should go in sufficiently far that the holes of the M3 nuts line up with the small holes in the end of the idler bracket.

Next begin to assemble the axis. Take the 428mm smooth rods and insert these into the large holes in the end of the X idler bracket. Then proceed to slide the linear bearings onto the smooth rods. Note the orientation of the bearings, when looking at the top/complex side of the idler bracket, two bearings go on the top bar with the one remaining bearing on the bottom bar as shown:

Ensure the rods are completely inserted into the X idler bracket, then insert the free end of the rods into the X motor bracket:

Step 1: X Motor assembly

| |

| Item | Quantity |

| Nema 17 Stepper Motor | 1 |

| MXL Printed Pulley | 1 |

| M3 Washer | 2 |

| M3x16 Cap Screw | 1 |

Start by inserting the the pulley nut works well), you can tap the end of the tube to place the pulley. Support the motor shaft, not the motor body, from the other end as you tap. You can secure the pulley with a drop of superglue if you like (make sure the shaft is completely free of grease). Take care that no glue gets near the shaft's entry to the motor. Note how both the motor and the pulley has a small flat in the shaft and the hole respectively. These need to be aligned and the flange of the pulley should be facing the end of the motor shaft as shown in the picture below.