RepRapPro Tricolour y axis assembly

Introduction | Frame assembly | Y axis assembly | X axis assembly | Z axis assembly | Heated bed assembly | Extruder drive assembly | Hot end assembly | Wiring | Power supply | Commissioning | Printing | Multi‑colour/multi‑materials | Colour Printing - Slic3r | Colour Printing - RepRapPro Slicer | Maintenance | Troubleshooting | Improvements

| A notice about these instructions! |

|

These instructions are open to editing by everyone and anyone. |

Contents

Goal

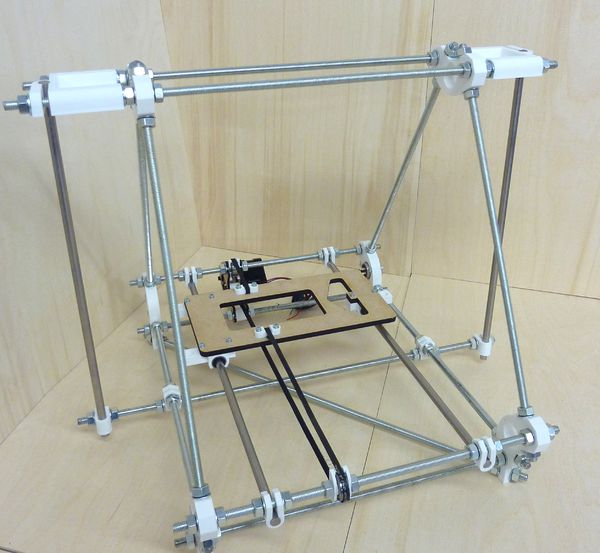

By the end of this stage, your machine should look like this:

Tools

You will need the following tools

- M8 (13mm) spanner

- Adjustable spanner

- M3 Allen key

- M3 spanner/nut runner

- Long-nosed pliers

- Side cutters

Step 1: Y Motor and Mount

| |

| Item | Quantity |

| Lasercut Y Motor Mounts | 2 |

| Printed Closed Spacer | 1 |

| Printed Open Spacer | 1 |

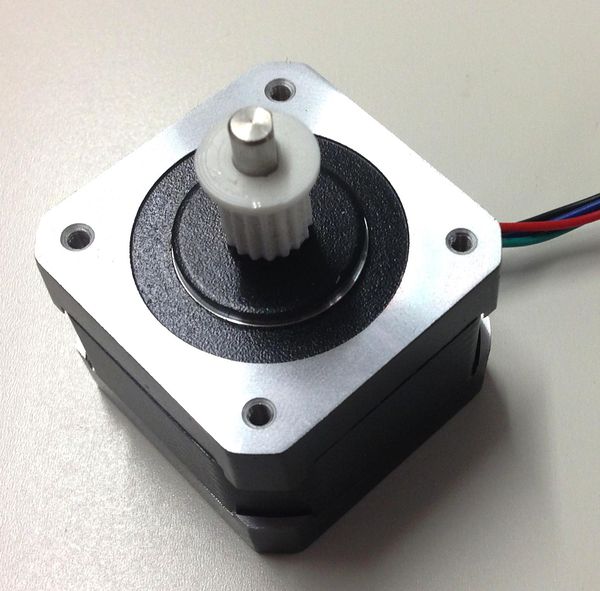

| Nema 17 Stepper Motor | 1 |

| Printed Belt Guide | 2 |

| M3 washers | 10 |

| M3x25mm cap screws | 2 |

| M3 nuts | 3 |

| 623 Bearings | 2 |

Motor Bracket Assembly

Begin by taking one of the MXL pulleys. These look similar to the extruder small gear, ensure you have the correct one. The MXL pulley is the taller of the twoThese simply push-fit onto the motor shaft.

Note how both the motor and the pulley has a small flat in the shaft and the hole respectively. These need to be aligned and the flange of the pulley should be facing the end of the motor shaft as shown in the picture below.

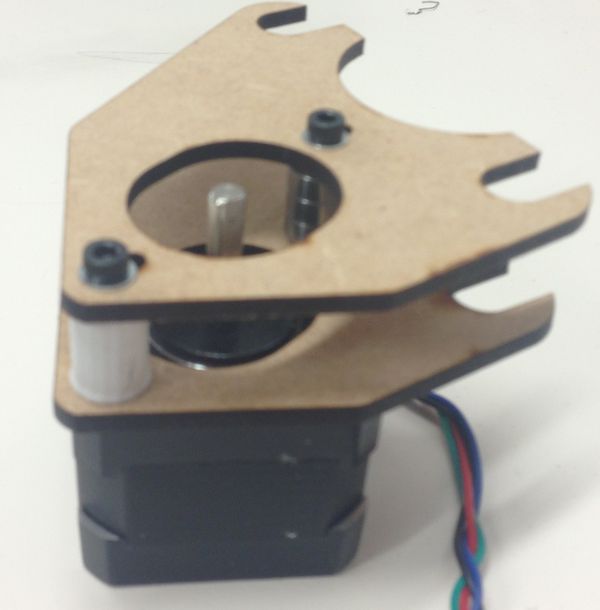

Now begin assembling the Y motor bracket. Insert one of the M3 cap screws and a washer through the slots in the motor mount furthest away from the semi-circular cut out. Insert this through the closed spacer and then finally through one of the slots of the other motor mount. The order is M3 Cap screw, washer, laser cut y motor mount, closed spacer, laser cut mount washer.

Repeat this for the remaining slot. However the closed spacer is replaced but two 623 bearings surrounded by 4 washers on either side. Now the order is M3 Cap Screw, washer, laser cut y motor mount, 4X M3 washer, 2X 623 bearing, 4X M3 washer, Finally attach this assembly the Nema 17 motors using the cap screws. The wire orientation should be facing the circular cut out of Y motor mount as shown.

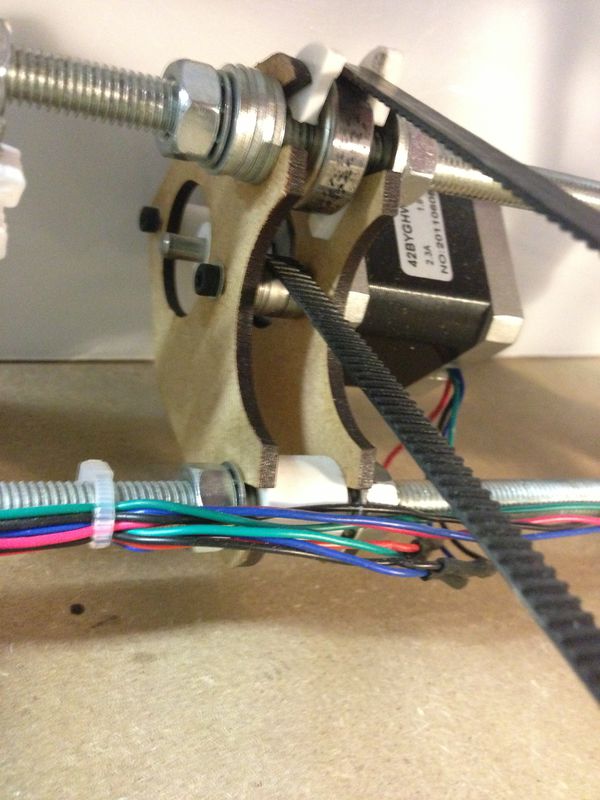

Next take this assembly and attach it to the frame at the rear of the machine. The motor mount assembly should be placed around the bearing at the back of the machine with a belt guide placed between the bearing and the motor mount. The order for the top bar is, M8 Nut, lock washer, Laser cut motor mount, belt guide (features facing towards the belt), bearing, belt guide (features facing towards the belt). laser cut motor mount, lock washer, nut.

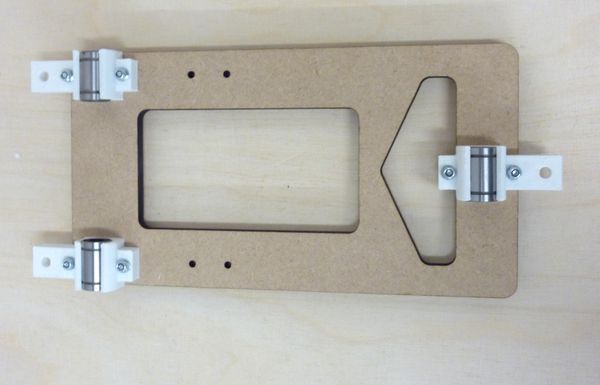

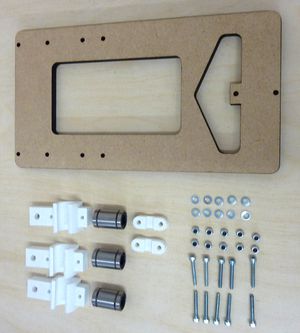

Step 2: Y Frog Assembly

| |

| Item | Quantity |

| Lasercut Frog | 1 |

| LM8uu Linear Bearings | 3 |

| Printed Bearing Holders | 3 |

| Printed belt clamps | 1 |

| M3x20 Cap screws | 10 |

| M3 Nylock nut | 10 |

| M3 Nut | 20 |

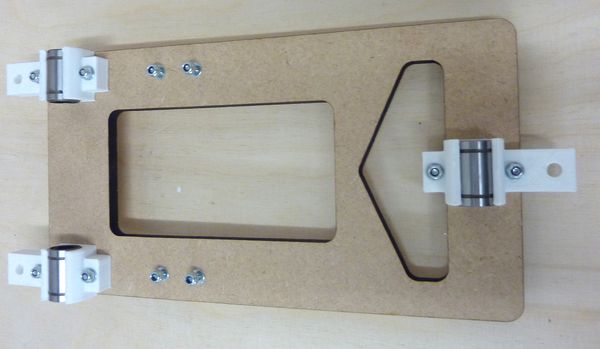

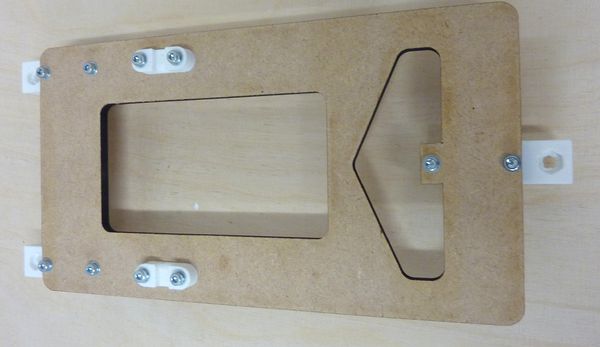

Attach the bearing holders to the lasercut part with 20mm cap screws, nylock nuts and washers (2 washers per screw, one on each side). You may find that there is a small bridge of printed material that needs to be drilled out to connect the hexagonal hole with the circle hole on the opposite side of the bearing holder. If this is the case use a 5mm drill bit and clean the part before attaching it to the Y frog. Don't tighten the nuts. Push the bearings into the bearing holders from the side as shown on the right. Do not try to clip them in from on top. The bearings should be a snug fit. But if they are a bit lose, simply wrap a little Kapton tape two or three times round the lose bearing. Get it flat without wrinkles or bubbles.

Next attach the two belt clamps to the frog on the opposite side compared to the bearing mounts. Use the remaining capscrews, with two washers and a nylock nut on each. At this stage these should remain loose:

Now loosen all off the Y bar clamps just enough that you

Next you need to ensure that the motor and idler bearings are aligned with the Y frog. Begin my moving the Y frog so that it is nearest the motor, loosen the M8 Nuts that secure the motor bracket, and ensure that the large bearing is directly opposite the belt clamps on the frog and re-tighten the M8 nuts:

Repeat this process for the Y idler bearing:

Next fit the belt. Loosen the belt clamp on the motor side slightly and inset the belt such that it's pointing towards the centre of the frog with the teeth facing upwards. Tighten the belt clamp, and then loop the belt up over the top of the clamp, over the bearing nearest the motor, around the pulley, over the top of the small idler bearings integrated into the clamp (so that more of the pulley is gripping the belt), around the Y idler bearings. The belt then may be secured using the spare clamp in the same manner as the first. So the belt should loop over the top of this clamp and back underneath. The belt tension should be fairly loose at this stage. Now loosen the M3 cap screws that secure the motor, you can slide it back and forth to adjust the tension. Adjust the tension such that the belt is tight, but not so tight that the axis begins to bind.

At this stage your machine should look like this: