RepRap Air

Release status: working

| Description | Simplified Prusa

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Main Features

Since I discovered the RepRap project I was surprised how much knowledge could be stored in an Internet community. I was impressed as a practical invention was able to born and grow in the network through the collaboration of specialists in various fields such as mechanics, electronics, computers ... all around the world.

In the mechanical field, It was a revolution when Josef Prusa got dramatically simplify the construction of a RepRap Mendel, current resulting Prusa, that has become a standard in building a RepRap. This also achieved make it much easier a person to be able to build a 3D printer.

The Prusa Air drinks from this spirit and tries to give a twist to the construction of a 3D printer. Its design is based on three basic principles:

1) To simplify the manufacturing and assembly (KISS principle).

2) Designing parts the cheapest way to be able to meet the requirements.

3) A little beauty.

With these guidelines, the use of RP parts is reduced for "commercial" pieces but always bearing in mind that they were readily available worldwide.

The changes are basically:

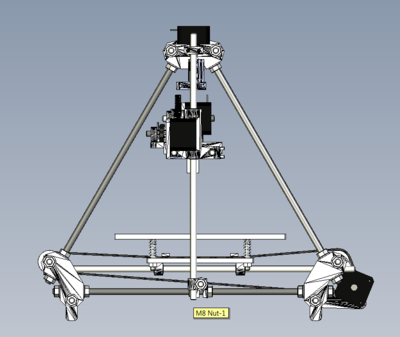

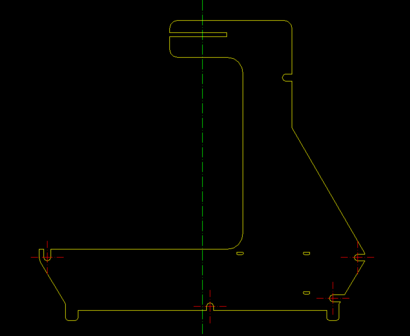

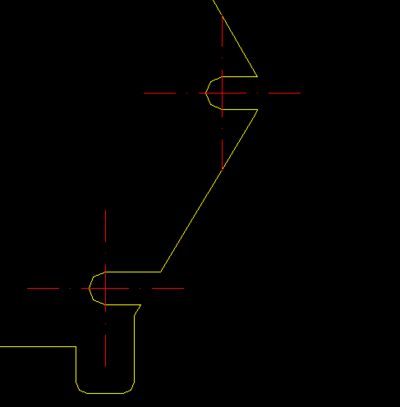

A) Most of the frame rods and RP pieces has been replaced by three pieces of acrylic embedded between them. They have followed all the design dimensions of Prusa, so for size, trips, electronics, firmwares... it works as a Prusa.

B) One of the sides of the typical Mendel triangle has been removed, resulting in a work area more accessible.

C) The holes for the rods have been changed so that the rods can be removed without having to completely unscrew the nuts.

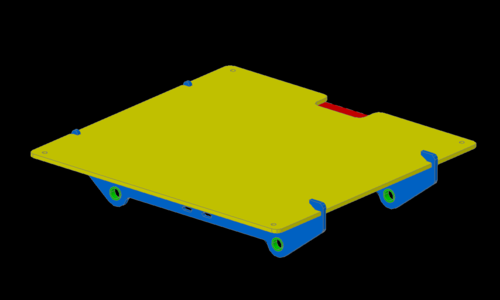

D) The X and Z axis haven’t changed, they are exactly the same of a Mendel Prusa, the Y axis, as the guides are placed in the same way, you can choose to place a traditional Y-axis or mount a Y-axis with integrated heated platform that you can see in thingiverse.

Bill Of Materials

Here are all the parts needed to build the printer, not including car parts for the X axis, or for the Y-axis platform because they are considered independent subsets and each person can choose which place.

Printed Parts

| Piece | Description | Quantity | Coment |

|---|---|---|---|

|

U-clamp | 6 | |

|

Endstop Holder | 3 | |

|

X End Idler | 1 | |

|

X End Motor | 1 | |

|

Y Motor Bracket | 1 | |

|

Z couplings | 2 | Can be replaced by: http://www.thingiverse.com/thing:9622 |

|

Pulley | 2 | Along with this will be a M3x8 grub screw and nut M3 |

|

PLA bushings | 4 |

Rods and screws

Threated rods

The threaded rods shall be steel, zinc plated and M8, the cuts required are:

4 x 285 mm

2 x 210 mm

1 x 430 mm

If you cut they from 1 meter rods you will need two rods, the best way to cut is:

Rod 1: 285 - 285 - 430 ========> Total 1000 mm

Rod 2: 285 - 285 - 210 - 210 ===> Total 990 mm

It's possible that the translation is wrong, the original was writen in Spanish. Feel free to correct it.