RepRec Pick & Place Robots

Release status: Concept

| Description | A self replicating pick and place robot made out of loads and loads of thumb sized 3D printed parts

|

| License | |

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

The replicating recomposer (proposed name RepRec) is a device that is meant to bring automated pick and place assembly to the masses. This of course includes the assembly of suitably designed RepRaps. RepRecs will be mainly assembling 3D printed parts but that does not necessarily exclude parts produced by other means like mass casting.

While:

- a RepRap can 3D-print its own parts for a copy of itself

- a RepRec can assemble its 3D-printed parts to a copy of itself to a RepRap or to an upgraded version of itself.

Symbiosis:

As there is a symbiosis between RepRaps and humans

there is symbiosis between RepRaps and RepRecs:

- RepRaps make parts for RepRecs (most of them)

- RepRecs assemble RepRaps (most of them)

Contents

The core idea

The problem: A cycle!

- Manual assembly labour forces the partcount of RepRaps to be low and consequently parts to be in a wide range of sizes.

- Parts in a wide size range forces manual assembly.

The solution: Breaking the cycle.

- Automated assembly allows to use very many small parts in a small size range. (No more minimization of part count.)

- Very many parts in a small size range allow for automated assembly.

Fewer vitamins! With manual labor taken out of the picture the vitamin to printed-part ratio (in partcount) can go way below 1%. With no hot-end filament-drive and print-bed almost all parts of a RepRec pick-and-place-robot can be printed. The only exceptions are electronics and motors.

The parts

A good size range for the parts of a RepRec would be ~5mm ... ~5cm (factor 10) compared to 0.3mm(M3-thread) ... 300m(length of threaded rod) (factor 1000) in many 3D printers.

Shape locking

The sub-problem-1: How to replace tiny metal screws with medium sized printed parts? Note: Clipping is taboo too. It is too weak for a serious design.

The sub-solution-1: To get rid of all the tiny screws all pieces are locked together merely by their shape. If the tolerances are kept very generous for easy "fall-in-assembly" even a bad RepRec can do the job.

Reinforcement

The sub-problem-2:

Now this method alone obviously makes ridiculously sloppy connections - almost like a piece of cloth.

So how to replace giant monolithic structural rods with rods out of mutually interlocked medium sized parts without getting a useless jelly-like meta structure?

The sub-solution-2:

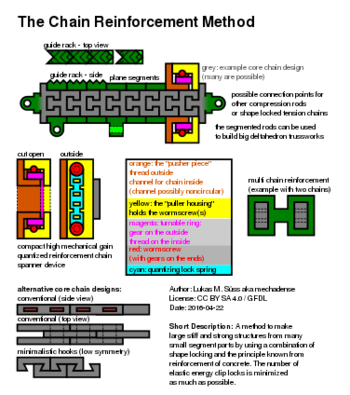

Stiffness in a structural framework can be archived through reinforcement very similar to the pre-tensioned rebars in concrete. For RepRecs this works by pulling on chains whichs segments are connected by shape locking alone and are spanned within the tubes that go through a big number of stacked short segments of profile struts. It can be a single chain or more for a bigger profile (e.g. 3). At one end the start of the chain-cores are widened such that they are prevented from sliding into the the starting profile-segment. At the other end the last chain-core-segments are pulled out of the last profile-segment by relatively large 3D printed screws (in the size scale of the chain). The fully assembled multi-part struts can be used to build up an even more rigid trusswork-frame.

Alternatively to tension the struts right away, If the strut is integrated in a trusswork and runs into a hinge where at least three multipart-(profile)-struts meet the (two) incoming chain-cores can be merged (one) outgoing tensioning core via a trivial mechanical differentials such as simple seesaws (this may not work but it's not a necessity for a working Reprec). This auto-equilibrates the tension and reduces the number of points to be finally tensioned. Seen topologically one could call this tension trees that are built up starting from the leaves moving to the trunk.

The points of where the frame structure is finally pensioned can include a 3D printed wormgear to get ultra compact high mechanical gain and finally a 3D printed ratcheting spring can lock the worm gear in place if the self holding friction is insufficient. Locking with a spring is a preferable design (scales down to slippery nanoscale).

Elements that take tensional loads instead of compressive loads like chains to tension a whole trusswork frame are easier to create.

In better RepRecs drive chains are also made from small printed pieces. For a basic RepRec at least seven drive-chains are needed (3-translate)+(3-rotate)+(1-gripper). Note: for a pick and place robot speed and accuracy does not need to be as high as for 3D-printers so a printed chain should work ok.

One method to tension a drive chain wrapped around two sprockets is to tension a rhombus out of four reinforced multi part struts. This way the pull-tensioned profile-struts push-tension the drive chain.

Example parts

- A shape locking chain that does not fall apart in free space (tension element) Thingiverse Shapelockchain I There is a version better suitable as drive-chain in the works

- A reinforcement rod demo is in the works.

- A trusswork node-point is in the works.

Design decision: stationary motors

Mounting the motors mobile onto moving axes (serial mechanics) may save some complexity as can be seen on the dollo 3D-printer but:

- They introduce quite a bit of inertial mass (well known).

- Organizing the cables nicely without resorting to vitamins (cable spirals) leads to bulky cable chains (that could equally be mechanical drive-chains).

- (The ulterior motive) At the nanoscale predicting mechanical behavior (quite classical) is much easier than predicting electrical behavior (quite quantum mechanical). Thus by factoring out electrical parts of the self replicating robot the design is more likely to be scaleable down to the nanoscale.

Distinction to other self replicating pick and place robots

The RepRec is not supposed to look like:

Matt Moses prefabricated block based "self replication modular manufacturing system":

Here's a video of parts of the self replication process.

Note: don't listen to the narration - Gregory Chirikjian only describes how the mechanics works and not what actually happens.

As I take it what happens in the video is:

- There's an extended mother Tron-Recognizer-like-3DOF-assembler-tower on two rail-tracks.

- It is extending its own rail-tracks. It assembles rail-tracks normal to the ones that it uses itself.

- It builds up an non-extended child Tron-Recognizer-like-3DOF-assembler-tower onto the new tracks that run normal to the one itself runs on.

A little earlier in the video there's a bit of introduction noting the concept of "parts complexity" (not necessarily related to the complexities I'll mention here).

Main differences between This and the here proposed RepRec is:

- A RepRec has much more diversity of part types (more external exposed complexity per part) more on that later in the adapter section.

- A RepRec has simpler smaller more passive parts (less internal enclosed complexity per part) more on that later in the adapter section.

- A RepRec does not use friction tightened screws but use down geared clip locked chain core reinforcement for stiffness. (and simple clip locks for "assemble-time" fixature)

- A RepRec may try to avoid linear rail designs (this is not absolute). If there are no linear rails the finished child must be pick and placed to new "replicating-robot-crystal-position" (ideally all six spacial directions are possible).

Gripping adapters - moving internal to external complexity

Self replicating pick-and-place robots with very low component/part specialization (that is very view generic part types like in Matt Moses design) would be useful for practical use if the constituent parts are small enough such that the created structures can be treated as a mechanical metamaterials. In this context small means almost imperceptible small by human senses. That is the parts must be at least under the 300 micron scale.

The purpose Matt Moses macroscopic design:

- Perfectly demonstrates the principle possibility of high degree self replication in a system of manageable complexity.

- It is impractical for making almost all of everyday utility stuff. At the macro-scale a robot that is using too few types of components/parts (including non included but handleable parts) just degrades to a "nonproductive replicator". A device that only exists for the sake of demonstrating the possibility of self replication. Without producing "nectar" a robot design has no chance of explosive growth.

To get a useful productive self replicating macro-scale pick-and-place robot there are two major things:

- (1) More external complexity (exposed for external function in post assembly time) must be invested in part prefabrication.

That is compromises on component/part design must be kept minimal. This is easy with 3D-printing where the "voxels" are under the required 300 micron for cube like blocks with limited external functionality.

Still the compromise of trying to reuse part-types (the same part design) is necessary to keep the number of part types and associated adapters low (wild guess: <300 ?)

- (2) Less internal complexity (enclosed for internal function in assembly time) must be kept in the design of the parts.

That is the parts can't be made to all have a point where they can be picked up with the same manipulator. Encoding The gripper-shape in all the parts is massive physical code duplication and leads to excessive physical space overhead. The interfaces to standard gripper(s) must be separated from the parts - especially the smaller ones.

The result is the need for a sufficiently wide set of part adapters. Or looked at it from the perspective of the manipulator head a set of specialized end effectors coupleable to the generic manipulation head(s).

Adapters of adapters may come up occasionally. Further stacking probably not. Obviously the adapters need to be well tensioned to the manipulation head when used.

Special parts / adapters / assemblies

- part adapters

- part magazines

- temporary clipping tools (to not need multiple manipulators at the same time - only for use in "assembly time" removed before "use time")

- tensioning tools (akin to screwdriver bits -- Note again: No locking of screws by friction intended in a RepRec!)

- LIFO pre-assembly templates (e.g. gear-bearing planet placement templates ...)

- FIFO pre-assembly templates (e.g. chain assembly "factory" mechanisms ...)

- DOF restrictors for not yet mounted but already assembled chains (e.g. a LIFO chain coil magazine from which chains can be rolled onto sprockets while permanently keeping tension! This is difficult but important. End-effector part assemblies for locking chains to loops are their own topic.)

Possible Designs

Design suggestion: parallel SCARA robot + 3+1-DOF rotation head

The FANUC M-1iA/0.5A robot has an interesting head serial mechanics 3-DOF rotating head that can turn all three hinges the full 360°. The internal workings of the head are very fine-grained and will by far not meet the "avoidance of small or special material parts" requirement for the RepRec. With major redesign it should be possible to meet this requirement. The head will become quite big and heavy though (wild guess: a little less that 20cm in diameter)

Beside the nice head there are problems with the delta-bot design though.

- There are a lot of non-planar hinges which are difficult to make compact with the design restriction of small component avoidance.

- A self replicating robot needs a quite big working volume to build its copies. To make it bigger the FANUC rotative arm drives in the top cupola could be changed to a linear rail design. But then coupling the three rods that drive the rotative head with statically mounted drive motors at the top will become very space wasting (long overstanding torsion-drive-rods). Thin torsion rods are a bad choice for low stiffness plastic anyway.

Parallel SCARA instead: What kind of robot design would lend itself well if one wants to transmit all the mechanical motions exclusively via chains to the top entrance side of the FANUC-style serial mechanics rotating head?

One possibility is a parallel SCARA design (similar to RepRap Morgan). Unlike a delta robot only hinges in two dimensions are present. It is easy to thread a chain drive through such a 2D-hinge by double-sprockets (to further hinges or like here to the head). Actually arbitrary many chains can just by stacked with just one design. Also with a parallel SCARA robot there's no need for chains to do two-dimensional translations via statically mounted motors. The parallel SCARA arms can be driven directly.

It is natural to supply the rotative head with a fourth chain (two chains of each side of the parallel SCARA bot). The one additional rotation available at the tip of the serial mechanics rotative head can be used for both clamping action and screwing action.

Adding a fifth or even a sixth chain should probably avoided since the head will get way to big, heavy, hard to assemble, unstable and whatnot. (Each DOF adds an onion-like shell to the head). Instead statically mounted simplistic counter actuators that are reachable from within the work-space (a simple possibly mechanically multiplexed clamp-board) should help a lot.

The hinges of a SCARA and the thereon stacked gear-bearings for chain sprockets can be made from split-sun-post-assembly-gear-bearings. By tensioning the whole bearing stack (clamping all the suns wit a common axle) the gap-backlashes of the bearings can be fully reduced to zero.

Compared to a delta-bot a SCARA design may have some minor shortcomings like:

- lower stiffness

- the scissor mechanism may be more in the way that a delta platform

- the z-axis must be handled separately (could be a good thing)

The double tripod

A design similar to Ralph Merkles double-tripod - just with linear drives

It can be found here: Zyvex nanotech 6dof there's a vrml 3D model available

This is a compromise between:

- the steward plattform (high stiffness low range of motion) and

- the serial robotic arm (low stiffness high range of motion)

FANUC style robot

A design similar to the "FANUC M-1iA/0.5A" robot - just with linear drives.

That is a chain driven linear rail delta-bot for bigger working area (instead of rotative direct stepper drive)

Maybe with the differences of a chain driven rotating head instead of the torsion rods??

Further reading

- SMT Pick-n-Place System

- The BrickRap is mostly composed of lots of small Bitbeam parts, which seems like the sort of thing RepRec is intended to assemble.

External Links

- Wikipedia: Deltahedron. Usable as components for a stiff frame trusswork.

- "Designing tensegrity modules for pedestrian bridges" by Landolf Rhode-Barbarigos1, Nizar Bel Hadj Ali, René Motro and Ian F.C. Smith1. Hollow tensegrity structures possibly usable as frame or frame components.

- A growing list of parts for partially self replicating productive nanosystems among other objects that just demonstrate novel principles encountered in future advanced atomically precise manufacturing.

- The dollo 3D Printer (especially the herringbone drives): [1] & [2]

- Serial mechanics rotating head patent used in the "FANUC M-1iA/0.5A" robot: [3]