Repemaker

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: working

| Description | Reprap 3d printer.

|

| License | Creative commons, atribution, no comercial, no derivs.

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | [[File:]]

|

| External Link |

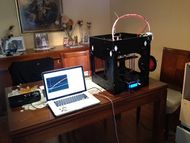

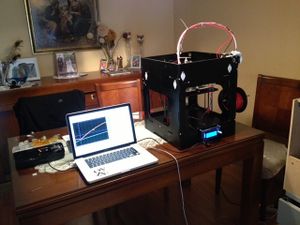

Repemaker 3d printer

The repemaker is an experimental 3D printer from FFF system ( Fuse Filament Fabrication ) . The main characteristics search accuracy and compactness . What distinguishes the other printers Repemaker Reprap operation is where x and y axes themselves serving to slide in one direction serve both to transmit the movement to the opposite axis . The structure of wood ( MDF ) closed gives it great stability and easy transport and placement. Both the electronics , with the power supply are under the structure so that the printer occupies approximately the same volume of a laser multifunction . The linear rodamientsos are IGUS brand for X and Y which makes operating the printer emits just noise (unlike ball bearings using other printers) brings space for a couple of buttons on the front for commissioning and lighting (optional ) . Like all Reprap printers ( replicants ) parts can be done in just a printer ... so it is possible to " replicate " .

Features:

Dimensions approx 40 cm wide by 40 long and 45 high. Great compactness.

Ease of transport. Holding the printer by two side openings can be transported very easily .

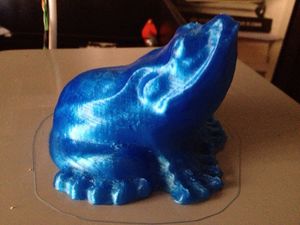

Hot bed . It allows the use not only of PLA but also other materials that need a heat source to paste the first layers

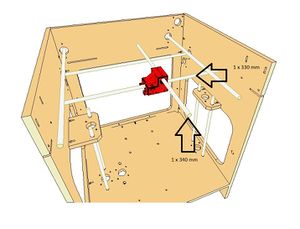

Z Axis engine and 4 double smooth bars . It does not work like other printers cantilever sliding around in the Z axis

X and Y axis smooth rod triple . The car is totally enclosed thus avoiding vibrations.

MDF wood structure . Affordable and high dimensional stability .

High stability and low vibration due

Electronic power supply and within the structure . All wires are left in the structure .

Bowden System , which allows higher speeds to move large masses not in the carriage.

High precision of movement.

Control Panel on the front (optional )

Double extruder (optional, two colors or a color and supports composite )

Very low noise bearings by IGUS

Ease of assembly structure with few parts and without calibration once assembled .

Development

The printer its totally functinall now. You can view the instructions in Spanish in (we are working in the translation):

Makealo

Movement

The movement is similar to the Ultimaker o Tantillus machine. Its very acurrate

Bill of Materials:

You can view the complete list in my web: Repemaker BOM

The printer parts can be download from: http://www.thingiverse.com/thing:138063

and

http://www.thingiverse.com/thing:151554

and http://www.thingiverse.com/thing:156444

Gallery