SeeMeCNC

Release status: working

| Description | |

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Introduction

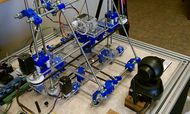

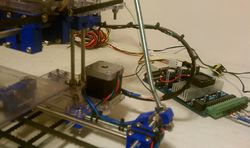

The SeeMeCNC H-1 design is based on the reprap Huxley. It is the first reprap style 3D printer to use injection molded plastic parts.

Our original goals were to produce as many parts as possible with injection molded parts, effectively lowering the price into DIY 3D printing, and turn to more conventional CNC technology, making it easier for newcomers to 3D printing and CNC machines. The H-1 is designed for standard SAE hardware. This includes the use of 1/4-20 threaded rods for the frame and Z axis lead-screws, 5-40 nuts/bolts for small sub assemblies, 10-32 nuts/bolts for others, and timing belts/pulleys designed around English units.

H-1 Build Instructions

All of these PDF's are built from the Solidworks Model, which all the injection mold tools were built from

File:71590 Steves Extruder Assembly.pdf

File:71584 Y Axis and Z Axis Assembl.pdf

File:71576 Z Axis Carriage Assembly.pdf

File:71574 Extruder Barrel Assembly.pdf

File:71579 Triple Bearing Sub Assembly.pdf

File:71578 Sub Assembly Double Bearing.pdf

File:71577 Combo Bearing Sub Assembly.pdf

File:71582 Z Axis Base Sub Assembly.pdf

File:71581 Rear Base Sub Assembly.pdf

File:H-1 Assembly Diagrams Complete.zip All of the assembly pdf's zipped up for download.

File:71580 Front Base Sub-Assembly.pdf

File:71523 Offset Support Rod Template SeeMeCNC.pdf

Build Notes

User generated SeeMeCNC-H1 Build Notes offer tips and advice you may find useful during your build

Supplies

All of the hardware should be readily available at local hardware stores. The plastic parts can be purchased from SeeMeCNC.com or from someone who has printed the parts from the CAD files.

Some parts, like the PTFE tubing and electronics, have come from sources other than local stores.

High Temp Silicone for installing thermistor/resistors is a great way to make those parts easily replaceable if ever you need to. Permatex Ultra Copper works best, as it's suited for 700F temps. It remains flexible and can easily be scraped off and re-applied if needed, and it's non-conductive.

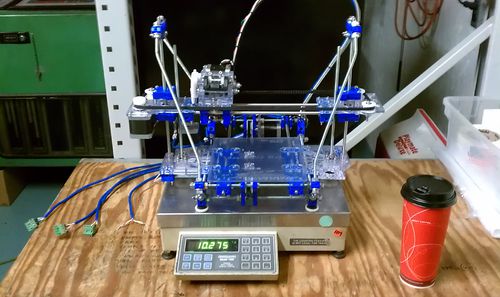

Dimensions

Approximate Build envelope is 6" X 7" X 6" Overall Machine Dimensions are appx. 18" X 18" X 12" Weight of machine with extruder and all motors installed (not counting any electronics) is around 10 lbs.

Injection Molded Parts

SeeMeCNC.com makes our own tooling and injection molds our own parts, through Partdaddy.com

Printed parts

Need sources for printed parts, CAD files are now uploaded to the files here, as well as SeeMeCNC.org

Electronics

SeeMeCNC is using Mach3 desktop CNC software for machine control.

Do not buy their electronics if you want to run an arduino based setup, just buy their hardware.

Note from John's testing on 12/27/11-when building the Ramsey(Velleman MK138) Temp Control Kit, replace R5 with an 18K resistor. This will allow the temp control to work up to about 480 degrees.

Software

SeeMeCNC is using modified versions of ReplicatorG and Skeinforge to generate g-code for Mach3 and similar CNC control softwares

Steppers

Standard NEMA 11 OR NEMA17 steppers.

NEMA17 steppers (4) provided in the kits are 66.6 oz-in Wantai 42GYBH811, see specs at: http://www.electronicaestudio.com/docs/PH3303.pdf

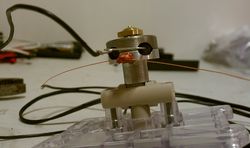

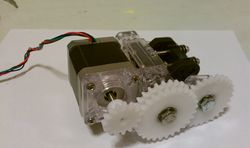

Extruder

Uses "Steve's Extruder", a gear-driven, dual driven pinch feed roller design. It uses either a NEMA 11 or NEMA 17 stepper motor. The hot-end uses two 6.8 Ohm resistors, and a 100K ohm thermistor for temperature control. The gear driven unit has a gear reduction ratio of appx. 6.5:1.

For Reference: If you put the (2) 6.8 ohm resistors in series, and run them at 24VDC, you will get the same power (42W) as using them in parallel at 12VDC.

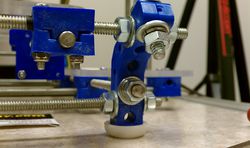

Timing belt

Timing Belts are XL, in 1/4" width.

X = 25-3/4" length, secured to rear of extruder carriage bearing blocks

Y = 41" length, secured to bottom of table

Z = 310XL closed loop (31" length)

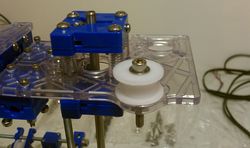

Bearings

The linear axis rollers use (stock) (32) Plastic Acetal molded bearings, or (custom) (32) R2ZZ (1/8ID x 3/8OD x .156W) ball bearings.

"Steve's Extruder" Uses (4) R4ZZ? 5/8" x 1/4" bearings

Z axis support plates use (2) R4ZZ? 5/8" X 1/4" bearings

Nuts and bolts

All hardware is standard inch units. 1/4-20 Threaded Rod 1/4 Drill Rod (for linear rod) 5-40 nuts/bolts for sub assembly of linear bearing plates The only hardware that is not a standard SAE size is the bolts for the steppers, which are 2.5 or 3 x .5 mm

To bend the 4 threaded rods(thanks, Yoyo): 1) Draw two lines on legal paper 3" apart. 2) Draw a 8.5" line connecting them 3) Take 9 nuts and screw them to the bottom of the threaded rod, all nuts abut each other and the last nut is flush with the end. 4) Take the 7/16" spanner, the same one you use for the other nuts and slide it about 1/4" above the top most nut. 5) Apply elbow grease and bend the rod until the angle matches that of the paper guide. 6) Repeat until done.

Ongoing development

Yahoo Groups page, compliments of Andy