Solidcore

SolidCore Printer

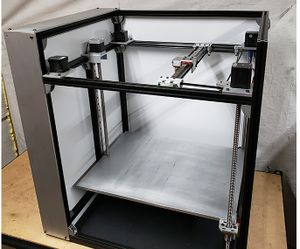

The solidcore (Corexy) printer is an ongoing project by 3D Distributed in Conroe, TX.

designed with a focus on being modular so that it can be reconfigured for additional tools and configurations. After moving the z-axis motors to the bottom of the printer we explored a simple setup that would allow the machine to either use three independent driven z-axis motors or a single driven motor with the belt path connecting to three z-axis lead screws.

ModularThe SolidCore design is a work in progress but our long-term goal is to build a modular platform, not just a printer. Think of it as an ecosystem of parts that can be arranged in different configurations and adapted for unique applications.

ModsThe motor and idler mounts are placed in the corners of the frame. This eliminates any design constraints of overall length and width. So if you need a printer to be a specific size or you already have a frame and rather not cut it down you’ll be able to use it. Eventually, we would like to have a spreadsheet or configuration tool that will allow you to input the current frame or linear rails that already own and output length and rail options. Or if you’re aiming for a specific print volume, you can input the data and it will output the frame and rail length options.

SolidCore Carriage The carriage and gantry are designed to be lightweight and strong. We currently use c-shaped aluminum stock because it is lightweight and faster to machine than solid stock. The reduced machining time and minimized waste helps reduce the cost of manufacturing.

The overall footprint of the machine relative to print volume is somewhat excessive. In order to have a solid enclosure design, I had to move the motors inside the frame boundary. This sacrificed the overall printer size to print volume ratio.

We’re aiming to balance the pull to the center of carriage instead of above it or below. It seems to be more rigid and minimizes deflection. The belts are somewhat within the same plane of the three linear rails to avoid rocking cantilever loads that other designs may have with the belts up high or down low.

At the moment the current build volume is about 350mm x 350mm x 350mm. Our next itteration will be around 400mm (z axis) and a 500x500mm build plate.

This design was inspired by the RailCore, HEVO, D-Bot, Mike Fisher’s QuadRod and Maarten van Lier’s corexy build.