User:Heisenberg Jones/Blog

Contents

- 1 Blog 1: Thingiverse Scavenger Hunt

- 2 Blog 2: Open Source Ecology

- 3 Blog 3: Robohand

- 4 Blog 4: Responses to Blog 2 of Classmates

- 5 Blog 5: Rep Rap Media Timeline

- 6 Blog 6: The Next Big Thing

- 7 Blog 7: To Share, Or Not to Share

- 8 Blog 8: IP and 3DP

- 9 Blog 9: Materials Hunt

- 10 Blog 10:

- 11 Blog 11: Show and Tell Revisited

Blog 1: Thingiverse Scavenger Hunt

My first task was to explore the open-source 3D model site Thingiverse and share various types of designs with the class. Thingiverse

1)Something amazing/beautiful

This stunning dragon must have taken ages to design. The level of detail put into the scales and face, not to mention the overhang of the wings and head, is incredible. I suppose the person who designed it was a graphic / mixed media artist to begin with, but it's neat to think that instead of being done by hand (where the subtractive medthod comes in handy for quick edits and detailing), this design was engineered to print out as one whole piece. Source

2)Something funny or strange

After several minutes of typing in random search terms in hopes of something mildly funny/unsettling, I typed in "fat", expecting a Peter Griffin head or Jabba the Hutt. Instead, I was treated to a file called Fat Bunbun, what I imagine someone on LSD would see while watching Bugs Bunny. While tempting to print out and present as a gift to your worst enemy, Fat Bunbun has only begun to haunt my dreams...the first night of many. Be warned: while appearing sluggish and stupid, Bunbun's creepiness is compensation enough. Source

Something useless

As someone who was never really into sports (YAY, we scored the points, now we just score more points than the other side, whoo), I already had a bias against these "glasses". However, from a purely functional role, these glasses fail. The point of these glasses is to show support for the 49ers, presumably during a game. I'll bet you can't see the person in front of you, let alone the court, if you wear these to the playoffs. Good effort, but seriously, this is like printing a blindfold. A pirate patch would have been more useful...at least then it can be fun. Source

Something useful

When searching for something useful, the term ubiquitous came to mind. This bottle opener can be assembled by inputting a coin of your choice, and the fact that one can adjust the slot for the coin based on currency/location is handy. But wait, there's more! Imagine: You're at a party with friends, having a good time. You see someone you like with an unopened bottle of...soda. Yeah. But, oh no! Looks like that guy everyone hates has stolen the only bottle opener in the joint. Aha, you say. Here's my chance to be a hero. Suavely walk over to the person you like, and say, "Can I borrow a quarter? I'll make it worth your while." Assemble this reusable bottle opener, open 'er up, and there you have it: you are now the life of the party. Also good for travel (avoid those metal detectors, then just use a coin from your wallet later). Source

Something which surprised me

This statue, while well made, seemed dangerous to be on Thingiverse. Simply put, I was surprised Disney had not sent an army of lawyers to contest their copyright claim on one of the most recognizable rodents in the world. Source

Overall, it was fun exploring Thingiverse and getting a taste for the possibilities of 3D printing. I even saw a model of a heart...seems like a good place to start for a side project or later assignment. From the coolest and most functional to the crappiest and bizarre, Thingiverse has it all.

Blog 2: Open Source Ecology

This week's task was to learn about Marcin Jakubowski's Open Source Ecology Project, a marriage between open source software and industrial machinery essential to jumpstart a civiliation. After delving into the history of the project and reading some reviews of Marcin's work, I had a bit to say on the topic.

1) What is OSE? What do they do? Are they legit?

The OSE GVCS (Global Village Construction Set) reminds me a lot of the G.E.C.K. (Garden of Eden Creation Kit) from the Fallout series: a one stop DIY jackpot ready to jumpstart a community. It aims to provide accessible agricultural and structural machinery to people looking for a functional unit whose schematics can be changed by the community based on direct user feedback (the OSE wiki), not a brand-name luxury device. It sounds like a dream come true for third-world farmers and just average DIY-ers. The goal is philanthropic enough, and has progressed steadily: from the time the TED talk was given, OSE went from 4 functioning industrial machines to 12, with 38 still to go. Along with that, a 3rd party group successfully reproduced one of their machines, the brick press, three years ago. I also found out that the entire team working at Factor e farm works on a meager budget of $4000/month, yet according to the Gantt chart below, are aiming to knock out 1-3 technologies per month while expanding. While I'm impressed with their ambition, I doubt that the 20-member staff can accomplish that level of production.

One thing I both appreciate and distaste is OSE's "build days". Marcin invited donors who donated $256 or more to the Kickstarter to "get their hands dirty" and help with the construction of a prototype. While it is a good way to gain capital, it would have been far better to hold an open-build day open to the public. It would have stirred up much interest, and shown that OSE was more community-oriented. OSE is, however, reaching out across the world, collaborating in open-source fashion. Overall, I give OSE the thumbs up, and believe that if they expand a bit more, the 50 piece GVCS will be completed before 2030.

2) A critique by The New Yorker, and Marcin's witty retort

While I could only access Page 1 of the New Yorker Article, I gleaned enough from that page and Marcin's response to get the main points. The New Yorker published an article about Marcin's Factor e farm in Missouri, and rather than focus on the devices and technology being developed there, they chose instead to write a profile piece on Marcin combined with a description of the "failed commune" he runs. They criticized the harsh living conditions on the farm, anything from extreme temperatures to lack of amenities. They make Marcin seem like a slave driver pushing his volunteers during the 40 hours/week of work. Marcin responded to The New Yorker's accusations with a post on the OSE wiki page with a fair amount of sardonic wit. He would rather they had focused on the goals of the project than the community he created, which he claimed was "only one instance of the numerous applications of our work." I found the New Yorker article to be, as Marcin put it, melodramatic. The volunteers at Factor e farm know what they are getting themselves into: they want to do a hard day's work and help test a bridge between open source software and the resulting hardware. If other people don't think the conditions are appropriate, why not judge monks living in harsh mountain monasteries in Nepal? In another publication, "Mechanical Engineering Magazine", Associate Editor Jeffrey Winters stated of OSE: "These guys aren’t Amish—they want to build their own car. They believe in technology. They just want it created and used at a more human scale." That said, Marcin does state that Factor e farm is "an experiment", and while the final result is unclear, he believes that recent organizational shifts (team and department leads), will prove useful. Also, he plans to build a recreational area for the workers on the farm, which may make the tough conditions a little more bearable. As an optimist at heart, I choose to side with Marcin; he is a man with a plan and an unceasing fount of enthusiasm for his dream. If others share his dream, they will join in.

3) What if OSE spread to PSU?

I can think of two professors here at PSU who would be interested in an OSE extension or club. Scarlett Miller, who taught my EDSGN 100 class, is interested in the Industrial Engineering Design process: how it has changed from the past, how different people brainstorm, and how designs evolve over time. This is reminiscent of Marcin's idea of OSE as an experiment; there is as much to learn about the process of prototyping as there is about the capabilities. The second professor I would want on my team is Dr. Stephen van Hook, a physics PhD and avid DIY-er. He has constructed his own guitar and many other various projects, and endorses community coming together through a student forum on a site called piazza. There, students are encouraged to work together to learn more.

Sources:

OSE Kickstarter Page [1]

The OSE wiki [2]

Wikipedia Article on OSE [3]

Marcin's 2011 TED Talk [4]

New yorker article: [5]

Marcin's response: [6]

Quote from Mechanical Engineering Magazine [7]

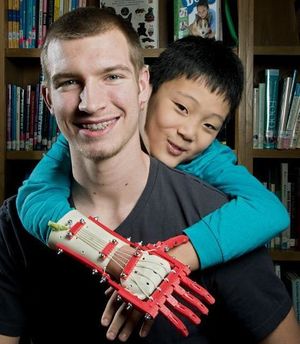

Blog 3: Robohand

How 3D Printing has the fundamental ability to improve a person's quality of life

Back in May of 2011, Robohand designer Richard Van As lost a finger and portions of his other fingers on his right hand. As a practicing woodworker in , he researched several prosthetics online, but it was only when he saw the work of mechanical prop designer Ivan Owen that he discovered a design concept he really liked. Basing their design off of puppets Owen had created, the pair originally meant to return the functionality of Robert's finger with a simple prosthetic. However, when they were asked to create a prosthetic hand for Liam, a boy who was born without fingers on one hand, they expanded their design. The very first Robohand was completed in November 2012 in Van As's native South Africa.

Now flash forward to January 2013. By this point, Makerbot had donated 2 3D printers to Van As and Owen, and their first design was up on Thingiverse [8], where it is still available for download. They established Robohand as an open-source service, and have helped 200 people to date. Richard put it best, when he said, "Not only did we find a design partner, but we’re kindred spirits in that we're both frustrated by the fact that there are some things that just shouldn’t be commercialized—they're needs instead of wants—that are." [9] Since the design to print the hand was available to everyone for free (Robohand accepts donations rather than charging), the design empowers amputees and those with limb difference alike across the globe. That's how 16 year old Mason Wilde was able to print a Robohand for Matthew, a boy in his hometown in Kansas.

The choice Van As and Owen made was a philanthropic one; they very well could have commercialized their product and sold it to humanitarian organizations, possibly copyrighting it. Instead, they worked furiously to get their project going for Liam and hundreds more in need. I believe it was Van As's experience of losing his dominant hand's ability that evoked this hectic pace, creating a functioning prototype in less than a year. The irony of the situation is that they received help from Makerbot. Makerbot was once a non-profit open source project as well, but today they have evolved into a popular DIY business, selling 3D printers for domestic and industrial use. In contrast, I could download the major components (sans harness) of the Robohand today for free, and have a functional hand printed in 8 hours.

The Robohand project has widespread exposure. The story of initial build was published in South Africa Popular Mechanics [10], tech news sites and blogs [11][12], and even the Wall Street Journal.[13] Other stories of Robohand changing the lives of people like Liam have also cropped up, on local news sites like Kansas City Star[14] and prolifically on the Robohand Blog.[15]

The article in the Star showcased the fact that anyone can use 3d printing to improve the lives of people around them. With good initiative and an urge to better the world, we can all be creators. While others choose to print gun components (that's a whole other story / fiasco), individuals like Mason, Van Ans, and Owen are choosing to create for good.

Blog 4: Responses to Blog 2 of Classmates

Many of my classmates had interesting points in their Blog 2 Posts about the OSE project.

Teammate Responses

My fellow teammates shared my positive sentiment regarding Marcin's project, at least generally. Drew made a good point that the expertise of the workers was an important issue to consider, for while many people may be inspired to join the Factor e farm, the potential success depends on their training. This resonated with my opinion that the training "build days" should be truly open source, serving as a means for anyone with interest and ideals to get a grasp on what building an agricultural machine in a day truly entails. He did admire Marcin's plan, though. Eric complimented the OSE initiative, praising its simple approach. I didn't include the idea of a simple life in my response, but Eric really connected with Marcin's vision. He preferred Marcin's simple, delocalized villages to the complex society in which we live today. Brian wrote a passionate response to the NY Times article. He was committed to the idea of OSE, stating that it has much potential. While it faces the problems of many startups, it is his belief that critics like Emily Eakin should give the project some time to develop before judging so harshly. Rather than envision societies based on this model, like Eric envisioned, Brian views OSE as a philanthropic endeavor, giving isolated communities the means to help themselves. I lean more towards Brian's opinion, for while provincial life would have its own rewards, I'm comfortable in a semi-urban environment. However, I really liked Eric's idea of applying OSE concepts to campus, like his open source rooftop gardens.

Class Responses

The posts of other members in the class varied tremendously. Eva praised the project, and focused on how the project was really striving to reach as many people as possible, utilizing several languages in it wiki and blog. This is a good point; while English is one of the most spoken languages on the planet, there are regions where other languages dominate, and using multiple languages broadens the target areas where GVCS could reach. Hao had a very good point on the safety concerns of the equipment; if people without proper machining and usage training attempt to build and operate the machines, they pose a danger to themselves and others. Even one of the earliest completed systems, the Tractor, has no safety information, with this posted on the wiki: "No structural engineering analysis has been performed on the LifeTrac III or IV. If you choose to replicate this product you are doing so at your own risk and with this understanding." [16] Jarred offered a poignant comparison between unskilled workers and the Invisible Hand of Economics, who believe that "things will fall into place" just by them being there. He also provided a solid prediction on how the BOT would feel about at OSE team here: not very enthused. Given the board's current stance on our 497J class, it is unlikely an adequate amount of seed money would be appropriated, no matter how beneficial the experience could be at what was ORIGINALLY AN AGRICULTURAL SCHOOL *cough cough*. Jess and most of the class agreed that while the NY Times article showed some areas for improvement, it focused too much on Marcin and the faults of the project, not the big picture. At times, she thought the article was an attack on Marcin's character, and his subsequent response was simple self defense. Nam Pham agreed, saying that it was ridiculous focusing on Marcin's yoga routine rather than the project itself. She also supported the project, praising its goals and saying that she would build one of these machines in her own time, given the resources. If she (a qualified Mechanical Engineering Grad) joined, she would help catalyze Marcin's project, without a doubt.

Blog 5: Rep Rap Media Timeline

"A Look at Recent Developments in the 3D Printing Timeline"

Looking at the Media Page from 2009 onward, several developments stick out and continue to reappear. From their start in 2009, Makerbot spread both their machines and their name throughout the world, from DIY enthusiasts, the Colbert Report, to facilitating projects like the Robohand and starting up Thingiverse. Arguably, this is a very important development in the progression of 3D printing, as it allowed generic access of the technology to the general public, albeit it at a cost. By seeing how many branch projects arose as a result (Robohand, hermit crab shell builds, modeling organs for surgery), it is evident that the spread of Makerbot will continue to pop up in the timeline for years to come. Although they have gone closed-source, their machines still fill the needs of many industries, and will continue to sell.

Another important milestone from 2009 was Organovo's successful bioprint of blood vessels, the first print of its kind. After that point, companies like Organovo and institutions continued to research and print tissues and biomaterials. In July 20009, researchers from UPenn and MIT had their crack at it, printing a miniature liver. Another group received funding to study printing meat meant for consumption...which has yet to pan out. An overhyped story was the "rat heart cell-powered printer", from November 2012. While a novel idea, using rat heart cells as a power source is not sustainable or efficient, and will not likely pan out.

In July 2012, the first gun was 3D printed, an issue which continues to stir controversy even today. Congress has attempted to approach the issue, seizing some printers and claiming the designers broke the Undetectable Firearms act. However, parts of guns (stocks, grips, lower receivers), were printed and demonstrated by Defense Distributed, whose goal is to stir up the public in support of 3D printing firearms freedom. In March 2013, The Liberator, a fully 3D printed gun (sans firing pin) was presented to the world. Issues with this branch of 3D printing are likely to continue. This is a topic I am concerned about, for gun regulation is a necessity in this age. Improper gun safety and ownership is a factor in school shootings, accidental death, and crime. By printing guns in one's home, it is possible for young children to see it as a common practice; printing guns from PLA would be reminiscent of NERF guns and other toy guns. This could be pretty bad in the long run, and requires a lot of thought.

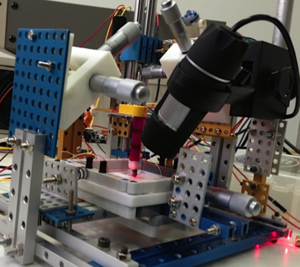

Blog 6: The Next Big Thing

What is the next step for PSU 3D printing?

In our class, we currently run Open Hybrid Mendels, printing one type of material (PLA). With these, we can print a variety of objects, and print more printer pieces. While this is great, the next step is already taking shape in the back of the room: the dual extruder. This development will allow us to print removable support material, multiple material prints, and has the potential to branch out into further areas (looking at you, bioprinting). An example would be printing cells and hydrogel, and then flushing out the hydrogel to leave the blood vessels behind. The printer in question would have to have precise temperature control and likely a new delivery system, so in terms of outfitting it it could be best to build a new one or add it to a partially built model. Thankfully, I may be working in a team outside of class to build a prototype. Dual extrusion could also allow for reinforced prints, using a light material for the main structure and a stronger material to build a mesh/interlocking rod support matrix. From heavy duty mechanical replacements or a stronger i-Phone case, the possibilities are great.

Another possibility would be composite printers, such as a Fibre Core extruder. This extruder uses a process called "pulltrusion" (pull + extrude) to pull a wire covered in expoxy through a melted plastic, and then extrude what is essentially an insulated wire. Other types of composite printers could lead to printing chips, wires, and other electronic components right into the object being printed! While the nozzle and feed line would need modification, the rest of our Mendels would be exactly the same. The prospective products from a fibre core could be as simple as coated wires or as complex as printing full electronic devices, no assembly required (although, that would involve a much more complex printer, essentially a small production line)

A third upgrade I could see in the near future would be a food printer, which I believe someone in the class is already interested in. Hershey has plans to start printing their chocolate via direct deposition, and a multiple extruder has already been constructed by MIT.[17] Using syringes to heat/store the materials as well as fans for rapid cooling, a different printer (perhaps a FAB), could be used as the basis for this.

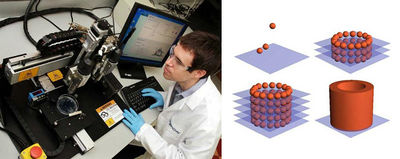

In which we learn how Open Source can benefit the world at large, but see its limited use regarding a really cool project

After reading this article[18] on the impact open source 3D printing will have on the developing world, what struck me was the optimism shown. I agree that open source would be a great step in allowing poorer communities access to affordable versions of professional scientific equipment and tools, such as the simple microscope shown on the left. However, the original cost for the printers needed can be around 500 dollars...a steep price, even if it is a solid investment in the long run. With grants from global programs like WHO as seed money, this could be viable, but if a rural community provides the funding, and the printer fails to meet their needs/expectations, the economic waste could be destabilizing, considering some families in these areas live on less than a dollar a day. That said, with help from seed money, this could be a valuable method of mass producing educational equipment to public schools. I admire this approach to empowering communities and connecting them with others; it's better to share knowledge than lock it away.

This leads me back into thinking about the OSE initiative, providing open source agricultural tools for communities everywhere. Other applications for this could be printing educational tools such as rulers and models of cells/bodies, affordable jewelry, or quick replacement parts for electronic devices. There are many ways a Rep Rap printer, internet, and open source designs could aid a 3rd world community, as long as there is a need to be met.

On the contrary is this article[19], describing a recent winner of the LEGONANO design competition. A multi-national team was tasked with designing and assembling a functional AFM (Atomic Force Microscope) from just LEGO's, Arduino micro-controllers, and 3D printed parts (shown on the right). While I admire their message of international collaboration, I wish they had made the design open source. It would allow access for other universities to save money, yes, but also show the value of building a highly functional machine in-house, using affordable 3D printing tech. This could jumpstart a revolution across higher education institutions, unless they were too snobby to do so. Instead, those involved in the design only took it back to their respective universities to complete more research on it, leaving commenters like Michael upset: "Don’t call the article “how to build a low-cost AFM…” unless there are actually instructions on how to build said AFM." Closed source limits the potential scientific wealth one shares with the world, and this AFM is no exception. Heck, we could print that device. The thermocouple looks quite similar to the ones we use in class, the parts are all either LEGO's, Arduinos, or 3D printed, and the occasional screws. If we could build it, so could smaller schools lacking funding, or foreign schools lacking the means to obtain higher quality devices only sold in distant countries. Yeah, if a team of grad students could build this in 5 days, having done the research before hand, it is feasible.

Blog 8: IP and 3DP

What are the different forms of Intellectual Property? What sorts of controls will be/should be enacted on 3D IP? Is 3D the end of IP?

Part 1: What is IP?

Intellectual Property (IP) is a system used by companies and individuals to protect their ideas, usually in order for them to make money off of. There are several types: copyright, patent, trademark, and trade secret. Copyright[20] is a method in which a person creates something, be it a new chemical dye, a script, or snack, and then holds the only rights to make and use that idea for their own purposes, for a certain amount of time. Within this time, they are expected to gain wealth from these individual rights, and after a number of years, the copyright expires. Copyrights can be both territorial (within states), but often today, are international. The user of a copyright must pay a fee in order to hold that copyright for a certain amount of time.

Next, is the Patent[21]. The patent is similar to the copyright in that it gives credit to a person for an idea, but is different in its application. Rather than allow that person to exclusively produce and use the idea, it instead focuses on keeping other people from claiming the idea. Inventors make money off of patents by making them public, and then selling them as commodities. Companies can purchase patents from their inventors, transferring the rights to that idea. Patents usually last 20 years. They are prevalent in the design industry, and have been the cause for many lawsuits. Patents are most applicable in R&D, but were originally precursors to copyright as "literary patents". Like copyrights, owners of a patent must pay maintenance fees to keep the patent theirs.

A Trademark[22] is a visible sign on a product or its packaging which is used to identify a legitimate item from a counterfeit one. It can be purchased by individuals, companies, and conglomerates. They can protect anything from company logos to toys and games. This form of IP helps its owners make money by lawsuits against counterfeiters, who are guilty of "brand piracy". Like the first two IP's, a TM has to be upkept by fees. There are different levels of protection for trademarks, including "registered trademark" (only for use by the owner of the trademark) and "trademark" (how non-owners of the trademark are to label it). Trademarks have to be used once every 5 years to continue service, otherwise, the idea covered is fair game for use. Fair use of a TM, such as in a documentary or parody, is allowed on certain grounds, either being used to identify a company (i.e. McDonald's in "Supersize Me"), or for humor. Unlike copyrights, which usually last for the duration of the creator's life + 60 years, trademarks can be renewed INDEFINITELY.

Trade secrets[23] are perhaps the most secretive of IP's. Unlike the previous 3, they are not privy to the public eye, and instead, are passed only within a company or group in order to further their business. Trade secrets can include formulas (as in Coca Cola), production methods (as Walter White's technique in Breaking Bad), and similar items. Trade secrets can be legally uncovered by reverse engineering, or illegally discovered by corporate spying, such as planting an employee from a competitor into another company (think of that creepy competitor of Willy Wonka trying to get Charlie to bring back one of Wonka's inventions so he could make them in his rival candy company). States develop their own laws regarding trade secret crimes. Usually, the only protection for trade secrets is a non-disclosure agreement, which employees sign and promise not to divulge the trade secret during and after their employment. This is the loosest form of IP, as it is the most vulnerable to exploitation, and there is no protection of the secret once it is exposed to the public.

Part 2: The Potential Demise of IP

Based on this article[24] by John. F. Hornick, 3D may mean the end (or at least severe narrowing) of current IP practices. He lists "the five I's" to describe why this is possible:

1. Infringement: If we can 3D print anything, the chances of printing something already protected under IP increases.

2. Identification: If people print these products in secret, with many channels of distribution, it becomes harder to track down "criminals" responsible for infringement.

3/4. Impractical/Impossible: Point 2 will make it much harder to pursue legal action against those who infringe.

5. Irrelevant: All theses factors will severely limit the current power of IP, eventually "nerfing" it.

Numbers 1-5 compound on one another, each making the next more likely. This is a logical progression. The maker movement takes place in garages and homes, not publicly visible platforms under government supervision. As DIY systems become more sophisticated as a result of collaborative innovation vs. the stunted growth of individual 3D printer companies, the gap of sophistication between homemade systems and professional ones will also diminish. Like Hornick said, people will be able to print more complex parts on their own, without the costs incurred by using a specific company's product. With the sharing mentality of maker culture, you very well may be able to "print a car", as told by an old commercial to prevent DVD piracy.

The 5 I's seem like a definite possibility. With people printing more and more complex items for their own use (we went from toys and jewelry to printing circuits into materials), the need for commercially made products may diminish. At the same time, areas of lower income / less availability will be unaffected, and will still buy consumer goods from internationally protected companies (think diapers, snack foods, motorcycles). Even with diminished IP, companies will still be able to sell their goods to areas where 3D printing is less likely to transform consumer culture. That said, IP will be weaker as it loses its hold on products sold in first/second world homes.

Creative Commons may serve as an intermediate, slowing the downfall of IP. CC will allow people to design 3D products and sell them to interested parties in order to gain revenue, but also allow non-business individuals to reproduce and use those products for non-commercial use, such as in their homes. This means that while some IP practices will be used to protect a product for commercial purposes, there will still be ways for DIY'rs to gain access to the product in a fully legal way. The implications of this are not clear currently, but may slightly alter Hornick's prediction.

Blog 9: Materials Hunt

I'm spicing the next few blogs up. In this one, I'll give information about different materials...but through the voice of a P.I.! Enjoy!

Chapter 1: Supplier Search

Detective Rupert Rapovich, Rup Rap for short, tossed yet another coil of PLA to the side. "Damn! More junk. Why can't a man find some good quality PLA these days?" He pulled out a notepad from his jacket pocket, crossing another name off the list. "Sigh, reliable suppliers are hard to find these days. Well, looks like we've got a live one: 3d2print[25], eh? Looks like they're wholesalers. A lot of bulk, for a low price, more bang for your buck, what could go wrong? There's not much here about the quality of their material, but they have a supporting staff and even cater to the needs of educational institutions. Their standard PLA price is $47/kilo. Guess I'll keep that in mind."

Flinching as he looked over Real KBell Engineering [26], an ebay supplier that had sold him the PLA of varying diameter, butchering some of his higher quality prints due to motor struggles. "While cheap, it's probably best to go to a company with their own website, even if I'm looking for average quality PLA. 12 USD / kg is way below the 45 USD/ kg average."

As Rup was about to turn a corner into a side street, a man with a thick German accent stopped him in his tracks. "Herr Rapovich! Just the man I wanted to see. I hear you're in the 3D printing business now. What if I told you I could get you 10 1kg spools of PLA for just 380 USD? Good deal, no?" "Yeah, sure," scoffed Rup, as he pushed past mexhibit [27], "if I wanted to pay shipping costs from Switzerland. Sure, you have standard PLA for that cost, but premium is 89/kilo, and is already made in the US...why can't I just buy some here?" mexhibit slumped, and said, "Herr Rup, well at least we ship to the US. One of the cheaper high quality PLA providers, 3dprintingcenter Israel[28], sells a high quality PLA for just 43 USD/kilo...but only sell in Israel!" "Yeah, better avoid companies that don't ship internationally," muttered Rup, continuing along the avenue he turned onto.

"Then again, I have to consider the printer I'm using. If I cave in to Makerbot[29] and buy their Makerbot2, they recommend using their PLA...but what if I want to use other brands? Will using a more affordabe / more reasonable PLA detract from my prints? Why not just get really affordable 1.75 mm PLA for my Makerbot from JustPLA [30], with 30 USD/ kg vs Makerbot's 48? It's highway robbery."

Crossing Makerbot off the list (perhaps with a few more lines than necessary...he had a grudge) Rub reached the last name on the list. It was I'll want to avoid using splurging on super-expensive PLA...this isn't gold we're printing here. What's the highest quality PLA on the market? Is it even worth investing in the highest quality PLA? Ideal PLA should have the same diameter, with only a ± 0.03 mm error, it should be packed and shipped well to prevent damage, and most importantly, it should be sold by a company experienced with the material they're selling, willing to negotiate if problems arise and be able to advise the best material for a specific printer. "Case closed," grumbled Rup Rap, as he reached his apartment.

Chapter 2: Materials Search

Rup awoke and made himself a cup of joe, picking up the paper from underneath his door. "Hm, an article about different printing materials[31]. Interesting. Oh, and here's another[32]"

PLA is best for novices to 3D printing. It has a typical range of 180-210 C. It requires more force to extrude, as it has a higher friction coefficient than ABS. It's best for new users because it is "stickier" than ABS, which makes it adhere better to the print bed. This is vital to prevent warping.

ABS is a stronger plastic. It also has a higher mp, from 220 to 270 C. It's best for more experienced printer users, seeking a higher quality print. It also requires less force to extrude than PLA. It gives a glossier finish to prints.

Chapter 3: Choose wisely

Rup eventually decided to go with 3mm PLA from JustPLA, as he was new at printing. The company seals its product properly, ships in the US, and seems to know their printing stuff.

Blog 10:

In a similar exploration to the previous blog (sans detective story), I take a look at different hot tips

1: Hot End Types

There are many different hotends in use today, but the most popular seem to be the J-Head, the MakerGear hot end, the Arcol, and the BUDASCHNOZZLE. The J-head seems to be the most popular, using a series of cooling vents to prevent the hot tip from melting plastic above the tip. It is lightweight, but requires extensive machining. However, it has a small number of parts[33]. Next is the Makergear Hot-end. Makergear is a respected 3D printer manufacturere, and their hotend is the one preferred if using a makergear product. It uses nichrome wire instead of a heat resistor like the J-head, which allows it to print at lower temperatures[34]. However, it is heavy to mount, has many parts, and can be on the pricey side. The Arcol is another heavier hotend, and is the standard for the PrusajrMendel[35]. It has complete separation of the hot and cold ends, is easy to assemble/disassemble, and requires minimal machining. It's goal is to limit heat spread. Finally, the BUDASCHNOZZLE is a larger, heavier hotend, but also gives good results. It comes pre-assembled, and has a variety of nozzle sizes available[36]. To choose a hotend suitable for a printer, one should decide on material to be printed, the permissible weight on the carriage, the nozzle size, the cost of the nozzle, and the lifespan.

2: Supplier Search

In terms of suppliers, I offer the example[37] of an authentic J-head nozzle from a reliable supplier[38] vs. a clone[39]. The easiest way to tell them apart is the number of grooves: authentic has 5, the clone has 4. The authentic hotend is machined correctly, has the right filament clearance, contains a PTFE liner necessary for PLA, and has a money-back/replacement guarantee from the distributor, RPW. The Clone, on the other hand, may be missing PFTE liner (impossible to print PLA now), is likely to fail, and has no money-back guarantee.

1: Choose wisely

I would go with an authentic J-head v5 for a new project. It is reliable, has solid reviews, and was machined properly, unlike some of the clones on the market.

Blog 11: Show and Tell Revisited

My peers gave some cool presentations in class this semester. Here's a recollection of one of my favorites

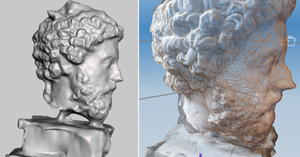

My friend Drew gave a presentation on the application of 3D scanning for 3D print model building. The idea is for someone to scan anything, from someone's face to the Taj Mahal, by taking several pictures from multiple perspectives. The images are then amalgamated into a nearly seamless 3D model. There have been several apps released to generate the basic 3D image, but they are not perfect. Some require many pictures in order to achieve fine results (upwards of 40). Furthermore, the scanned models may have gaps or missing sections, while a solid model is needed for the g-code. While there are some programs which can be used to get these kinks out, Drew mentioned that a closed source app known as Autodesk123D that fixes these errors in-house. Another topic he mentioned was the creation of an online database of images, a sort of google for 3D scanning. Users would upload different photos of a location or building, from various angles and distances, and the database would compile all these images into a single 3D model. While this project would be open source, Autodesk123D is closed source, which somewhat limits its capabilities.

Drew then showed us his own experimentation with the app, which he used to produce a 3D model of his boot. After taking many pictures, editing, and finally getting an stl file, Drew sliced his model and printed it out. This example just shows how 3D printing is becoming more accessible to the public, as a novelty for now, but spreading quickly. For more serious purposes, these apps could be used in the medical field, such as when doctors used a 3D model created from an MRI scan of a patient's heart to get a more tangible feel for the procedure they were to perform on them. Drew has continued exploring 3D scanning for his project, and I'm excited to see where he goes with it next.