User:Snc5178/Prntr

Sam Carroll's RepRap Wiki

Info, Blogs, Projects, more!

Main | My Printer | Class Blog

The following serves multiple purposes as an experience blog, build guide, and promotion of the MendelMax 1.5.

Release status: working

| Description | A true reprap; printed brackets, with the rigidity of aluminium extrusions.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Basic Info

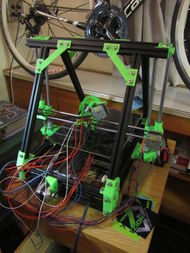

I built the MendelMax 1.5 RepRap 3D printer. With designs for the MendelMax 2 already out and kits available, it may seem like I built an outdated printer. However, I chose to build the 1.5 instead of the 2.0 because it is more in the spirit of RepRaps, and is more similar to the systems I'm already used to using, the Open Hybrid Mendel. The 2.0 systems are a lot more commercial looking, with more metal parts instead of printed parts. I thought that the 1.5 is a good combination of the values I'm looking for: structurally stable, easilly replicable, cheep materials, quality prints, and adaptable.

Sourcing Of Materials

I obtained all of my parts from two suppliers.

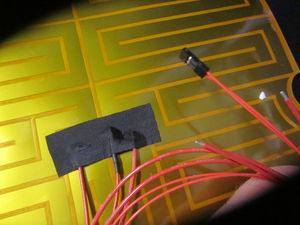

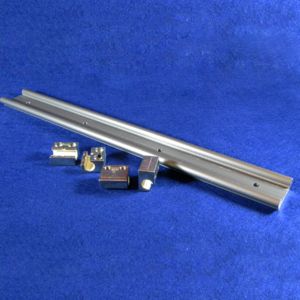

All metal parts: aluminum 20X20 mm extrusions, Z axis lead screws, smooth rod, MendelMax 2.0 Y axis, nuts, bolts, etc came from Maker's Tool Works, as one unit, the MendelMax 1.5 Hardware Kit. This is a great kit that includes everything you need to build the MendelMax 1.5 on thingiverse linked in the banner on the right. The aluminum extrusions come cut to lenght and the ends are already tapped with the necessary M5 threads. Another nice part of the kit was the Y-Axis, it is a single, solid, piece of metal that the bed rides on. By having a single beam, this eliminates troubles aligning dual rods. The Y axis is very low friction and is SOLID, no play found here. The bed is a 3 part system made of a thin sheet of aluminum, to which you stuck the heating pad, and a glass pane.

Positives:

- All hardware from one ordered item

- Precut, Drilled, Threaded, 20X20 mm aluminum extrusions

- Unique single rail Y axis

- Quick Delivery

Negaties:

- One hole was overlooked and wasn't threaded, I was able to do it myself at the Learning Factory.

- The kit is based on hardware needed to build the version on thingiverse, so it doesn't have hardware for modified versions. Also the leadscrews that they sent me didn't match with my printed parts. This is an issue of different sources, not with MTW.

- The way the bed is attached isn't very sturdy. thers some tip from side to side, but this shouldn't be a problem once leveled.

Package Arrival Heated bed heater

All printed parts, electronics, cables, hot tip, and filament were sourced from Maker Geeks.

Positives:

- Quality customer service: I emailed him, pretty sure it's just one guy, twice with various questions. He responded promptly and answered all of my quesitons.

- Printed parts available on request in any PLA color offered

- Wide variety of materials, and lots of relatively cheap kits.

- Pre-soldered electronics arduino and RAMPS 1.4

Negatives:

- Printed parts were low infill density ~0.1

- J-Head MKIV Hotend sucks it's the knock off from China, it has a really low sloped tip and the extruding plastic has a tendency to curl and stick to the head.

- NEMA 17 Stepper Motors were of the low torque version with only 3 inch long wires that had clips on them that didn't mesh with the wire bundle sold by MakerGeeks.

Package Arrival, Items, Printed Parts

Y Axis 2.0

I think this is a serious improvement over the two bar systems. Maker's Tool Works produces a single rail system with carts. I believe that this can be adapted and also hacked together on our systems. We could use like the green T posts and 3D Print or machine our own cars. The part I think can be improved is the way the bed is attached. It may be better once I have more experience with it; It does offer an easy leveling system. However, right now it seems a little unstable.

MTW: Y Rail & Cars VS Standard U Posts

Difficulties

I ran into problems because I got the printed parts from a different source than the hardware. The harware had really nice leadscrews that aren't any sort of standard threading. The printed parts expected you to use nuts traped into the parts to thread the rods through. To solve this probelm I simply screwed the leadscrews through the plastic parts. It's working as a temporary fix until I can print new X axis ends. It creates excess friction in my opinion and isn't a good long term solution.

THe hot end has a low slope to the tip and has the tencency to reheat anything sticking up which then sticks to the hot tip and drags the part on the bed. You have to be really careful to get the first layer or two down without error.

Useful Links

I followed the two guides below to completely assemble the frame of my printer. It is a good guide if you're using all the parts that they use. However, you're on your own if you have different printed parts or hardware.

Here is an amazing build guide by Trinity Labs for all of the MendelMax 1.5 frame. Build Manual

Here is an amssembly guide for the Y Axis 2.0 Assembly Guide