User:Tms5308

Contents

Introduction

My name is Tom Stewart and I am currently a super senior industrial engineer at Penn State who plans on graduating in December of 2013. I enjoy making tasty jams on my drum set, being physically active whenever it's necessary, and riding my bike on mountains. I heard about 3D printing only two years ago and have been infatuated ever since. At first I was intimidated by the visual complexity of the RepRap printers but once I started to get my hands dirty I felt like a kid again playing with Lego's with 3D printing capabilities. Get involved, it's one of the only classes at Penn State where you get graded for having fun.

BLOGS

This section will be reserved for weekly blogs with various prompts given by the course instructor.

Blog One

A) Something that is beautiful

In my opinion the horse head statue demonstrates an amazingly beautiful 3D printed sculpture. It looks to be solely decorative but for good reasons. The detail and complexity of the design are two aspects that caught my immediate attention. It is also amazing because of the size of the design and it was successfully printed without (or very minor) print defects. The .stl file can be downloaded [http://www.thingiverse.com/thing:131460/ here.

B) Something that is funny/strange

I can see where a device like this would be useful but the design is surely flawed, if you notice from the picture. It is strange that the creator chose to build the silverware holder with the points of the forks and knives pointing up. Openly exposed edges such as these ones can be a serious risk in the kitchen, especially with the high risk of spills that can occur on a kitchen floor. A design like this would be better used if it contained utensils like serving spoons, spatulas, rubber scrapers, and other cooking tools with round and harmless exposed features. I consider myself a person who has always had a good sense of coordination who would not casually swipe my hand across an area with exposed knives, but accidents happen so there is no reason to bring forth that risk when there are safer and equally as efficient ways to store silverware. The .stl file can be downloaded http://www.thingiverse.com/thing:121941/ here.

C) Something useless

There are many other ways to remind yourself what day of the week it is, and this item is an eye sore in the garden. I don't think an item resembling a calendar is ideal for a garden because there is no correlation, it seems very random and kind of looks like birth control pill organizer. This item could have other uses, or been a little more specific because it only tells you the day of the week, no month or day of the month. Adding this design to a garden as a yard decoration definitely does not seem ideal, and the owner might occasionally forget to switch the days which defeats the purpose of having it in the first place. The .stl file can be downloaded http://www.thingiverse.com/thing:139504/ here.

D) Something useful

Being able to print devices like this one here are in my opinion why additive manufacturing is the new age industrial revolution. If industrial manufacturing companies become reliant on the capabilities of 3D printing to create their parts it is safe to say this new rapidly growing technology has solidified its spot as a new style of manufacturing industrial parts. The .stl file can be downloaded http://www.thingiverse.com/thing:109839/ here.

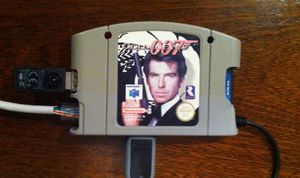

E) Best Rasberry Pi case

Searching through the various Rasberry Pi cases that people have made, I found this one to be the most clever with a relatively simple design. With a case like this one, the designer also still has room for artistic originality. An N64 game label could be created on the front cover but it does not need to be limited to this. Many other creative designs could be capable to put on the front cover. One good thing that might also be useful is to design the name of each separate Rasperry Pi device so they can easily be told apart. But aside from the artistic freedom, the dimensions and housing of an N64 case will work out comfortably with the Rasberry Pi units. The .jpeg file can be found http://www.gpforums.co.nz/thread/446101/8/ here.

Blog Two

It is hard to believe that additive manufacturing has been around for two decades and it has only recently started to make a large buzz in the manufacturing industry. This is because certain industrial markets started to use 3D printed parts as final products in their manufacturing process. In the past parts have only been printed as prototypes hence the name "rapid prototyping" but research and technological advancements are proving that prototypes are no longer the main focus. This is a huge milestone for additive manufacturing because with successful penetration into industrial markets will bring forth a surge of repeating business with companies who are willing to significant amounts of money for 3D printed parts. These prices that companies are agreeing to pay however are still much less than what they are use to in the past. Specialized machining is not necessary for parts that are made via additive manufacturing because the printers are capable of producing parts with intricate designs in a matter of hours. One industry that has been really taking advantage of the benefits of additive manufacturing is the aerospace industry. Stratasys has been successful with their Fused Deposition Modeling (FDM) technology in creating parts that have good temperature, ultraviolet, and chemical resistance as well as having the specifications to pass FST regulations. This is allowing the aerospace industry to produce parts at a low volume but they are being used for several different applications. This is crucial for additive manufacturing because companies will see that 3D printed parts are being used as final parts in certain industries which will provide the drive to get involved in additive manufacturing so they can remain a successful competitor in the corresponding industrial sector. Companies are becoming more intrigued in the advancements being made so they are having parts printed for them or even purchasing their own equipment in order to stay competitive in their market by partaking the most innovative and cost efficient manufacturing processes.

Blog Three

I was very intrigued by Leo Funk's second blog as I am currently working on a project for a class that involves expanding the 3D printing network within the Penn State community. I agree with Leo when he talks about how unavailable 3D printing can be unless if you’re associated with company or organization. Many people do not realize how common it is becoming and the capabilities of 3D printing only keeps growing with time. A resource such as 3D Hubs is an excellent thing for the world of additive manufacturing because not only does it connect people with an interest or need for 3D printing but it also spreads the knowledge of availability. One thing Leo mentioned briefly I thought to be a significant about 3D Hubs is the fact that its purpose is to put 3D printing into the hands of everyone. This could obviously be crucial for the advancements of additive manufacturing because if more people know about it and realize how much it is being used then it has the potential to become the norm, which is a good thing. Once people start viewing 3D printing as a normal part of life that is when it will become implemented into more businesses since more people trust its capabilities and see the various uses of additive manufacturing. Spreading the word and gaining more exposure is exactly what additive manufacturing needs, currently people are either unaware or uncertain and the only way to defeat those thoughts is to make it a more prominent aspect of our society.

After looking through Pat Mangen's blog, I enjoyed what he had to say in his posts but I wish he would have kept his commentary consistent in blog #1. From a reader’s perspective I think it would have been in Pat’s best interest to provide pictures and comments about the various designs that he believed fit into the respective categories. I find it to be slightly annoying to have to relocate to another web page in order to understand what he is talking about. He provided a comment about one of the items he found but for some reason did not do that with any other category, which is inconsistent and does not seem to be complete.

I enjoyed the blog of Dimitar, I thought his layout was quite organized and he also cares about its upkeep since he took advice from other classmates on how to make his blog look nice. His first blog’s layout is very convenient and easy to read. I like how he made the category the link to Thingiverse and had each design in its own box, and he also provides a short description of why he believes that design fits the category. In his second blog I also enjoy how he gives his own advice on how to make his interest come to life, this shows that he has put thought into a design previously and is sincere about infatuation with a 3D printer and scanner as one unit.

Blog Four

The following commentary is referring to this video: https://www.youtube.com/watch?v=2j84BDoNkt8

Whenever Adrian Bowyer, David Cuartielles and their team created the Arduino technology then decided to make it open source was probably a questionable decision to some, but in their minds, there was no other option. They valued the advancements of the technology more than they did the possible financial gains. They knew however, that as the technology spread then certain business opportunities to make money would fall into place. In the video they talked about companies like Google and Firefox giving away their main product for free then getting involved in certain side ventures which make the companies money so they can continue improving their work. David’s team was very interested in seeing the possibilities for the Arduino which could be achieved by making it available to the world. People started doing things with it that they had never thought of which is in part what they were hoping for. This can be considered a risky business plan since most business have their own patents and intellectual property so people can only get that specific product or service from that specific company. The Arduino team figured that their product could become much more prominent and useful if everyone where to have access so they can assist in making it better and broadening the scope of possible uses.

If I were part of their team I would have been a little skeptical at first to give our technology to the world for free, especially after all the work put in to create it. After seeing the possibilities of the Arduino and understanding how different people can use it for seemingly endless applications, it was surely a good decision. From the graph shown in the video of the increased number of Arduino users over the years, one can see that this technology has become exponentially more popular which opened up many opportunities for the team who created the technology and as a result their profits started following a similar exponential trend.

Blog Five

The following commentary is based upon these two articles: http://www.publicknowledge.org/Copyright-3DPrinting http://betabeat.com/2011/04/3d-printing-hits-a-strange-milestone-shape-pirates-and-copyright-claims/

After reading the article, “What’s the Deal with copyright and 3D Printing?” and reassessing the objects I chose for the first blog, I can definitely see some potentially copyrightable aspects to some of the models. The horsehead sculpture was modeled after an original stone piece which was most likely created by another artist. The artistic nature of this model would put in under the category of things that are acceptable for a copyright. The original artist created the sculpture then the 3D model was designed from it which could infringe on the artistic rights. Another object that could potentially infringe on copyright laws is the object for something useful, the grip to car gear shifter. The specific design I have posted is pretty standard and would need qualify for a copyright, however there could be other designs that are more artistic which would be separated from the actual handle. There could potentially be a company logo or design that is an extra part of the shifter which could be copyrighted but the shifter itself is too common of an object to qualify for a copyright by itself. In Brandon Tunkel's blog number one, for the useless category he discusses a sculpture from the game series Dead Space. The design already has a copyright as it is connected to that particular video game. The creators definitely want that object to remain specific to the game Dead Space. Hamad’s useful item shows a belt buckle which was discussed in the article. In the case of a belt buckle the ultimate deciding factor is if the artistic aspects of the design are primary or secondary to the functionality of the buckle. The design that Hamad discusses would not be approved for a copyright because the artistic elements of the belt are secondary. It is a standard belt buckle with a little design carved out. If the buckle were more unique and actually change the way the belt worked then it would be considered okay to be approved for a copyright. Licensing non-copyrightable files can be beneficial for legal purposes as well as cultural purposes. On the legal side when a person licenses non-copyrightable files they are basically protecting it from falling into some other copyright law that might be implemented in the future. This allows a person to continue to improve an object or design regardless of how laws change in the future. Licensing non-copyrightable files for cultural purposes can be very beneficial. The creator is interested for their work to be exposed to a certain community who can help to improve the design or use the design to spark other ideas and creations. When referring to the article, “3D Printing Hits a Strange Milestone: Shape Pirates and Copyright Claims” the author can be considered naïve because Ulrich Schwanitz did not create the Penrose Triangle himself, he only figured out a model that would be compatible for 3D printing. If Ulrich were the original artist then it would have been a different story, but since he was just copying an already existing piece of art he had no right in claiming that it was his own property. Also, the Penrose Triangle is an optical illusion which are usually outside the scope of a copyright.

Blog Six

After reading through my classmate’s blogs about copyright and patent laws it seems as if the article, "What’s the Deal with Copyright and 3D Printing?", gave everyone a pretty good understanding of the differences between the two and where they should each be applied. Matt Digel did a nice job of summarizing the article and explaining what he had learned after reading it. Then in a very clear and concise way he reevaluated his parts from blog one as well as a few classmate’s items. Ian Beavers also had a relatively involved post as he examined the parts from five different blogs. This is definitely beneficial to do because it gives one the opportunity to read everyone’s interpretation of the 3D printing copyright article as well as see how everyone else categorized their parts from blog one when taking copyright and patent laws into consideration.

Blog Seven

The following commentary is based off of this article: http://3dprintingindustry.com/2013/10/17/pinhole-3d-printed-camera-technology-made-simple/

This article a 3D printed pinhole camera that uses natural sunlight that pours into a tiny hole to imprint the photons reflected off the surrounding environment onto a piece of film which creates the negative for a photograph. The use of 3D printing for technology such as this is a match made in heaven because the overall design is meant to be slightly simplified which means lower end printers can be used to produce these cameras. A person could build their very own RepRap printer then very easily print one of these pinhole cameras. If a product such as a camera can be made from the use of 3D printers, then this idea surely opens up the doors for other common objects that can be added to the pool of printable designs. Some actually prefer these pinhole cameras for taking pictures because it captures the image in a way that is impossible when using a lens and the only thing that needs to be replenished is the film. When using 3D printing for designs such as this camera one would hope that it would spark the interest of some and intrigue people in continuing to push the envelope. Items such as this pinhole camera are very exciting because who would have ever thought we would be 3D printing cameras that actually work. Even though it is a very cool concept, it is still limited in certain ways that will keep it in a niche market. With the technology available today it is silly to think that these cameras would ever take the place of digital cameras. Today's cameras have many more functions than capturing images, and there is even so much variation in how one can capture an image. The personal digital cameras are also so convenient to use and photos can be printed right from home and only need the time it takes to print for development. For reasons such as ease of use, convenience, functionality 3D printed pinhole cameras will never dominate the market but in turn it will spark brilliant ideas for those with innovative minds.

Blog Eight

The following projects can be found here: http://blog.reprap.org/2013/08/announcing-amri-advanced-manufacturing.html

The first project off of the ARMI site is an open source selective laser sintering printer. This project discusses the steps that have been taken and experiments that have been carried out in order to develop a successful laser sintering printer. A big experiment in this project is the use of a milling machine to create different materials to print with. Different sized milling balls were tested in order to figure out what size produced the most ideal particles. There were also other experiments performed that focused on mechanical and electrical aspects of the printer in order to increase the effectiveness of the machine.

The second project on the ARMI site is to improve ink jet printing using RepRap technology. The first initiative is to figure out how to implement ink jet print heads with RepRap mechanics. Instead of a standard extrusion nozzle this machine will have ink jet print heads mounted where the nozzle would normally be. The corresponding electronics will also need to be successfully integrated into the system to create a fully functional printer. Experiments are being done to test the accuracy of the ink jet nozzle; these experiments entail various droplet testing to determine a good ratio between spread and density of the material being used to print with.

The third project on the ARMI site is digital light projection 3D printer. There currently two main areas of focus for this project, containment of UV light and print adhesion. For the containment of the UV light, the problem is most likely due to the use of a clear print bed which absorbs the light which then reflects it to the surrounding areas. This could potentially be resolved by making the print bed opaque. Also, the prints have not been sticking to the print bed possibly because spray paint was used to make the print bed not see through any more. The paint made the bed slick which it why the prints won’t stick. This could be resolved by experimenting with different print bed materials, or materials to put on the print bed with better adhesion qualities.

The fourth project on the ARMI site is an extruder that can print using cells. This is a twenty milliliter syringe extruder that is capable of liquid extrusion at the microliter level. This will be used for research in synthetic biology, biological pattern formation, and engineering of cellular logic.

I believe that all of these projects are valuable because they are really advancing the possibilities of 3D printing using RepRap technology. It is essential to push these limits in order to make new discoveries and to find out what potential is present for the advancement of this technology. One thing that might be interesting to experiment with is the use of powder metallurgy using RepRap technology to produce higher quality and stronger parts.

Here are some other adjectives that can be used to describe the PSU RepRap movement: hands on, 3D printing, tinker, build, problem solving, ground breaking discoveries

Here are some ideas for memorable words or acronyms that describe the PSU RepRap movement: PennPrint3d: this uses the first part of Penn State and the word printed with a 3d at the end to include 3D printing in the name POSSABLE: Penn state Open Source Student Academic Based Learning Experience

What I Do In Class

This section will be dedicated to keeping an account of my experiences each day of class.

Journal One

10/29/2013

Unfortunately I did not think to keep an account of my experiences in EDSGN 497J until tonight, but later is better than never I suppose and since it has been such a memorable opportunity I have a good idea of everything that has happened so far regarding the construction of my first RepRap 3D printer. These posts will focus on weekly updates of the construction process and issues I came across as well as how each dilemma was resolved, plus anything else I deem worthy (cool successful prints, print issues, print fixes, new design ideas, etc).

During the first few weeks of class I designated myself as one of the printer repairmen, so out of the printers that were already built I would conduct prints and see if there were any resulting issues then figure out how to fix those issues. I figured this would be a good way to start off the class since I was getting experience on how to properly print as well the mechanical side of how the printers are designed. I quickly realized how intuitive working with the RepRaps can be which turned me on to them because I was not dealing with something that was way outside the realm of my understanding. After those few weeks passed and more printers started producing parts that met the intended specifications I decided that the number of repairmen could decrease and I moved on to a different project. I began constructing one of the unfinished printers. The frame of the printer was assembled for the most part so the first thing I started with was attaching the fixed z rods and z-axis motors. One of the first major issues I came across was that the slots of the z-motor carriages did not match up with the screw holes of the z-motors. To solve this issue I filed down the holes in the z-motor carriages so it was possible to line a screw up through the holes to tighten the motor down. This was quite the process since the filing took a while to ensure the perfect amount of material was shaved off in the right direction so the z-motor would remain snug when screwed down. After that dilemma was resolved I moved on to attaching the mechanism of where the z-axis meets the x-axis. The x-axis portion was already assembled so all I had to do was thread the spinning z-rods through the embedded bolts then attach the rods to the motor so the printer would have a mechanically functional z-axis. This task was another that proved to be a little more difficult than I had anticipated. I successfully assembled everything but it was a challenge to get the z-axis to spin smoothly. There is too much resistance in the spin which could be due to a number of reasons that I am still trying to narrow down. Making sure the two rods are parallel and vertical are a crucial aspects and to me they look to be this way but I obviously still have some adjusting to do since movement in the z-direction is not fluent. I moved on to the print bed because there was still construction to be done and perfection can be achieved through tweaking at a later date, in the meantime I had many other sections to complete. The print bed being used for the printer I am building is smaller than the ones the class has used in past semesters. This was no serious issue, I just had to use a smaller bar that runs perpendicular to the y-axis that connects the pieces that hold the print bed in place while it moves in the y-direction. This also meant that I had to move the parallel y-bars closer together so the rollers would fit properly and slide effortlessly along the y-axis. The holes were aligned between the bed and its holder then I drilled them into the print bed to attach the two. The printed springs used between the bed and holder were too long for the screws we had available so I cut the printed springs in half which proved to work just fine. After the print bed assembly was complete I popped it onto the y-bars and adjusted them slightly to find the happy medium of where movement was very smooth. Before I left class tonight I attached the y-belt but need to decrease tension or make other adjustments so y movement is fluent and can be easily moved by the motor.

References

1. [[1]]