User:Virtlink/DIYRap

As a replicating rapid prototyping machine, the RepRap is not very good at replicating itself. In fact, currently no RepRap can replicate anything other than its plastic parts. A RepRap without printed parts would not be replicating, and thus not worthy of its name: it's a Rap, without the Rep.

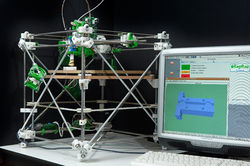

When looking at the progression of the RepRap designs, then one thing is immediately obvious: less is more. The Darwin was a complex bulky box of metal and plastic parts. The Mendel is a more sleek prism-shaped machine that uses less metal and less plastic than its predecessor. Now take a look at the latest Prusa: it uses again less metal and less plastic parts. Some people even built it without plastic parts in the frame.

When building your first RepRap, you'll have to source the parts. The more effort you put in comparing prices and shops, the best deal you're gonna get. But... the more specialized the part is, the more you're going to pay for it. You can get threaded rods at your local hardware store, but only the handful RepRap shops in your country sell RAMPS or plastic parts. Reduced competition and lack of alternatives results in higher prices and reduced quality. But it is possible to save money and time by using less specialized components and less different components overall. Less is more.

Finally, the RepRap's components are far from standardized. This is great when trying to improve the existing designs, but really cumbersome when buying parts for your RepRap: you'll have no idea what design the seller used for the plastics or the PCBs, or what length threaded rods you have to order. Heated bed or not? Linear bearings or PLA bushings? Wade's or Greg's? If only there were tried-and-tested RepRap designs that left no doubt as to which versions and designs of the components you'd have to use...

I present (by lack of a better name) the DIYRap, a Rap without the Rep, whose goals are:

- Reduced number of specialty components (including plastics);

- Reduced number of different components (e.g. no more M3, M4, M8, M10 hell);

- Increased used of commonly available components (e.g. things you can buy at the local hardware store and electronics shop);

- Stable tried-and-tested designs for first-time RepRappers to build.

Further reading

- RepRap Breeder, more ideas on how to speed up the time from "I wish I had a 3D printer" to "I have built a 3D printer".

- RepRap User Groups (Category:RUG) can help -- seeing 3 working printers in front of me leaves no doubt that at least those 3 designs are tried-and-tested.