User:Wenxin Song/blog

For this class we write weekly blogs on a variety of topics that have to do with 3D printing.

Contents

- 1 Blog 1: Thingiverse

- 2 Blog 2: OSE PROJECT

- 3 Blog 3: Kansas teen uses 3-D printer to make hand for boy

- 4 Blog 4: learning from other people's blogs

- 5 Blog 5: RepRap Media timeline

- 6 Blog 6: Would there be a twist on 3-D printing so far?

- 7 Blog 6: bonus blog

- 8 Blog 7: 3D printing could offer developing world savings on replica lab kit

- 9 Blog 8: 3D Printing and the Future (or Demise) of Intellectual Property

- 10 Blog 9: filament materials and suppliers

- 11 Blog 10: designs I think are most reliable

Blog 1: Thingiverse

We had to explore around on Thingiverse and find different items.

http://www.thingiverse.com/thing:30889

An item that is amazing/beautiful

This Droplet Vase catches my eyes immediately when searching the website.

I like its smooth white surface and wander how many times been tried before the final one came out without any flaw.

http://www.thingiverse.com/thing:27053

An item that is funny or strange

This makes me remember the lovely Paul the Octopus, which came to worldwide attention with his accurate predictions in the 2010 World Cup.

http://www.thingiverse.com/thing:225080

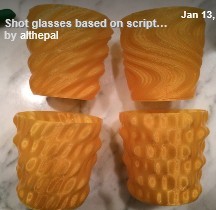

An item that is useless

I don't know what these glasses could be used for anyway. Especially I don't like the strange shape and color.

http://www.thingiverse.com/thing:234783

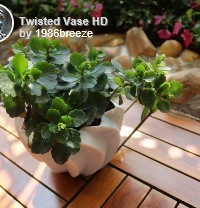

An item that is useful

I like this cute vase as well as the lovely green leaves. It can not only for planting but also for decorating.

http://www.thingiverse.com/thing:61796

An item that surprised me

This item is really amazing. How could the printer printed such delicate thing!

Blog 2: OSE PROJECT

We were asked to research about OSE projects and respond to the following:

A) I want your general impressions of the OSE project; positive, negative, utopian, etc. Please do a bit more research than just viewing the video, as it is now several years old and they have made some progress since then. Links to more recent videos and media will earn you a better blog.

Marcin Jakubowski's speech, Open-sourced blueprints for civilization, presented a new idea to us in 2011. Making tools that is robust, highly efficient optimized, low cost, made of local and recycle materials. It sounds quite reasonable cause we always want to make the most profit at the lowest cost, especially in the fast developing manufacture. For the past two years, he and his teammates did some try such as laser cutter, iron worker, tractors, microhouse, etc.

I do stand positively on constructing new idea for making more efficient hardware to convenient our life. The question is, all the stuff could be done in mass manufacture with less time and effort according to the high technology. What if we apply the new idea by using modern technology, not just by our hands. Maybe that will increase the efficiency.

B) The New Yorker magazine recently had a fairly critical article regarding Marcin's OSE project. Find/link that article and summarize its critique. Marcin had a response to that: I'd like your response to both of these pieces.

http://www.newyorker.com/reporting/2013/12/23/131223fa_fact_eakin

Just as the picture shown on the page above. The main idea I think is that Marcin's OSE project is not realistic. Because few people want to create these stuffs by hand just as in the article. "His project, the Global Village Construction Set, has attracted a following, but among the obstacles he has faced is a dearth of skilled acolytes: the people who show up at his farm typically display more enthusiasm for his ideas than expertise with a lathe or a band saw." In the fast speed modern life, all we want may be spending the least time to do the most job. Marcin and his teammates spent 60 days on 6 machines. I really appreciate his determination and effort but we need to consider the time cost. Since now the most expensive thing is time. With time we could do anything but without nothing. As a result, efficiency should be put the first place when we start our projects.

Marcin responded to the critical article:

http://opensourceecology.org/wiki/New_Yorker_-_Article_Response

Marcin stated eight reasons to support his projects.

Well, I could understand the situation of Financial Bootstrapping. Since it often happens to a new born idea, especially with few people supporting. But let us find the reason by ourselves. Is it because the self-funding operation separating itself from the current life. We live in a high developed society and we get used to the convenient life brought by modern technology.

As the pictures showed, we could loose interest in Marcin's project cause we could show interest in these self-made houses. At first, we may feel fresh to do all these construction by ourselves. But what about a month?

C) Imagine we want to create capabilities similar to what Marcin has made at PSU (something like an OSE student club, or another effort). I don't think the administration or trustees would support such a thing, but there might be professors who are interested in supporting such a thing. Do you know any of them? What do they do, and why do you think they would be interested in such a project? Imagine you are looking for allies to do such a thing. Whom is on your list and why?

Well, it is not realistic to have projects to build a microhouse or tractor in the lab on campus. But I do think we could try some small stuffs maybe just for fun.

Blog 3: Kansas teen uses 3-D printer to make hand for boy

Who created this design and when/where was it done?

Ivan Owen co-designed the original 3-D printer Robohand with Richard Van As, a South African woodworker in 2012. The two made their first prototype in November of 2012 and had a 3D printer version by January of 2013. Mason Wilde modified the plans to make a device that would fit the boy’s small hand. Using a 3-D printer at the Johnson County Library, Wilde made a prosthetic hand that opens and closes and can even hold a pencil.

If you wanted to make one, where would you go to get it?

If I wanted to print a prosthetic hand, I may search the website Thingiverse for an appropriate one. Or maybe I could try to write the code for a new one.

How many news articles can you find which reference this technology?

http://www.ubergizmo.com/2014/02/boy-receives-3d-printed-prosthetic-hand/ http://www.csmonitor.com/The-Culture/Family/Modern-Parenthood/2013/1104/3-D-printing-Dad-builds-prosthetic-hand-for-son http://www.psfk.com/2013/05/robohand-3d-printed-prosthetic.html#!uFYJJ http://www.npr.org/blogs/health/2013/06/18/191279201/3-d-printer-brings-dexterity-to-children-with-no-fingers http://www.gizmag.com/easton-lachappelle-3d-printed-prosthetic/28685/

Blog 4: learning from other people's blogs

I read about several classmates' blogs about Open Source Ecology Project Discussion and find something ideal really open my mind. For example, in Kevin's blog two, he cares about whether there will be outside force to cripple the open source project when it is still in its developing stage. Even though the open source community descried in the website is a little similar to be utopian, the OSE community do want to make contributions to human life. Just like a new born child, we don't know how great he could be when he grows up. We need to give him hope and courage.

Besides, I quite agree with one idea in Anthony's blog. That is "While I think that OSE is a great way for people to be able to make their own machines to run a farm at a low cost I don’t think it’s “a civilization starter kit.”" The modern high developed society could be a strong evidence that our civilization's start is quite successful. We don't have to begin at the zero step to develop a new civilization. What is more meaningful is to make improvements to the existing tools, which makes more sense cause it costs least and makes the most progress.

Another good point made by Lee catches my eyes immediately. He doubts the one statement Marcin says "regarding average people rising to the occasion and creating their own machines." Since many of us are average people, we can hardly do as easily as Marcin says. Even I am a graduate student in electrical engineering, I don't think I could build up a tractor like him does. It cost much human energy and wisdom. If one project couldn't reach most of people then what is the feasibility of it?

Brian's blog two shows his inclusive attitude to Marcin's project. What I want to say is similar that only by accepting different things and idea could the society develop in harmony. Why we have to be so mean to any new idea which may not appeal us. Let's think in others' ways and we may find that sometimes we are actually to stubborn.

At the end, I would like to quote Tom's one sentence in blog two which actually has the same idea with me. "However, I feel that a more realistic goal would be for a person to take on a machine where they can offer the utmost level of expertise. Having a small group of people force out numerous machines is not the way to yield the best results." That is the point I get in my blog two.

Blog 5: RepRap Media timeline

1) An event very important in the progression of 3D printing technology (open source or not) 2012 June 15; Guitar manufacturing is revolutionized by 3D printing (Doesburg for theguardian) link

2) A not so important event in the progression of this technology (something overhyped perhaps?)

2012 April 30; Behrokh Khoshnevis, Professor of Industrial & Systems Engineering and is the Director of Manufacturing Engineering Graduate Program at the University of Southern California (USC) brings the idea of 3D printing to automate the construction of buildings, maybe one day you can 3D print your own house link

3) Something which you found interesting which you would like to think or speak more about.

2012 November 12; Voxeljet 3D printer used to produce Skyfall's Aston Martin stunt double (Hearn for engadget) link

The filmmakers of the latest Bond movie, Skyfall, tasked 3D printing company Voxeljet with sculpting 1:3 scale stunt doubles of James' latest whip, the Aston Martin DB5. Luckily, no real vehicles were harmed in the making of the film, but these 18-piece scale models were. Check out the photos within the article!

I would say that interest me so much cause I my undergraduate major was TV engineering and I also had an internship in TV broadcasting station where I met some directors who direct and do post production for short films. I went with them to the shooting sites and saw how they use props. That was so amazing if the 3-D printer could provide props which could be used in the films.

Blog 6: Would there be a twist on 3-D printing so far?

When I worked with my group mates I came up with an idea. Could I print an object made of iron? Then I was frustrated cause the temperature to melt iron would then melt everything of the printer. In that case, I realize the limitation of 3-D printing which means that the objects printed by the existing 3-D printers could be used in limited area. Which also means that if the applications of 3-D printing couldn't be used widely enough it may stop on the current step. since now what we print are mostly small components of the machine.

Then I need to find the original reason leads to the limitation is that the material used to print. What comes into my mind is that if the 3-D printer could print clothes, bags? The idea seems not to be weird cause the luxury fashion is popular these days all over the world and the profit made by these so-called luxury things is beyond imagination. What if a 3-D printer could print a Louis Vuitton bag or a pair of Chanel shoes?

If we want to catch eyes from more and more people on 3-D printing maybe we need to appeal what people like. In this case we need to do research on the world's trend not only in fashion which is just one aspect of the world-wide trend.

Blog 6: bonus blog

Since I am learning pattern recognition now as a graduate course now and try to think about if it could be also used in 3-D printing. The 3-D printing is actually really rigid cause it could only do what the G-code ask it to do. While what always happens is that there will be errors when doing the printing. For example one step couldn't be done well and affect the whole shape of the object. There would always be flaws there because the printer couldn't recognize what's happening wrong when printing. If the printer could recognize the printing process and when something goes wrong it could know how to solve the problem in the most fast ways. That links more to the machine learning and artificial intelligence which could make the 3-D printers more smart.

Then comes the problem that we need to program the printing process so that the whole process is under control not only by human-beings but also the printer itself. That would definitely improve the efficiency of the printing but also needs more effort on the research of 3-D printing.

Blog 7: 3D printing could offer developing world savings on replica lab kit

It is kind of true that high technology always appears firstly in developed countries cause they have time and money to support people doing research and inventing new technologies. Imagining in developing countries, people seldom have accesses to those high techniques and advanced machines, their manufacture is low efficient which would lead to wasting more time and energy of human-beings so that a bad circulation to this country. The idea of appropriate technology to deal with poverty was used as early as the 1970s by the World Health Organisation (WHO), when villagers were encouraged to make water pumps and farming tools. But 3D printing has given the concept a boost. Suppose every farmer has a 3-D printer in their houses and they could print whatever they need by the printer. It is also very essential that the resources of soft programs and related links could be accessed to each person with free.

It is a progress because the access for anyone means that everyone could has a chance to study and learn science and technologies whenever and wherever they want. Also each person has different idea and they could invent new things or improve the existing machines, tools by themselves according to their own imagination.

Blog 8: 3D Printing and the Future (or Demise) of Intellectual Property

Because the fast development of 3-D printers, people's life become more and more convenient. We could easily download soft programs form the Internet and upload the new things been printed or modeled on the website and make them available to everybody!

IP is protected in law by, for example, patents, copyright and trademarks, which enable people to earn recognition or financial benefit from what they invent or create. By striking the right balance between the interests of innovators and the wider public interest, the IP system aims to foster an environment in which creativity and innovation can flourish.

Will 3D printing things with virtually any functionality, away from control,cripple traditional manufacturing ? Think of Internet piracy in the film industry. The ability to share films on the Internet has substantially changed the film industry. A century later, movies are a global passion – for the millions who watch them every day and for the hundreds of thousands who work in the global film industry. The writers and actors, directors and producers, the editors, composers and designers, the sound and light technicians, the creators of special effects and new technologies: each one contributing their spark of creativity and innovative genius to this most collaborative of works. With more films coming from more countries every day – and more means of dissemination, on screens large and small – we all benefit. The movies have come a long way since Chaplin’s Tramp. But their effect on us – the pleasure, and the passion – remains the same.

This year, we look behind the scenes to find out how IP rights shape the filmmaker’s journey from script to screen, how film producers attract investors, how screenwriters and actors earn a living, and how innovation is pushing the frontiers of creativity in the industry. The same can happen to traditional manufacturers of things when it becomes possible to 3D print things with virtually any functionality, away from control.

Blog 9: filament materials and suppliers

Do some searching to find links which are useful. They may be aggregated suppliers, filament reviews, or other sorts of content on the subject. Apply your brain to the following problems. Find links. Post them in your blog. Explain why you think they contain useful content.

ROBO 3D PRINTER link

PLA filament link

ABS filament link

ALIBABA link

There are many criteria for evaluating the quality of filament. Take PLA for example.

TYPE

The ordinary PLA: A(clear natural),C(opaque color)

Better PLA: 3, A(clear natural),B(toughness translucent color,our technical innovation products),C(opaque color)

PROCESSING TEMPERATURE The ordinary PLA: 210 deg Better PLA: 185 deg

ORDER The ordinary PLA: No, smoke, taste like fried corn Better PLA: No smoke, taste like fried corn

DIAMETER VARIATIONS The ordinary PLA: 1.56-1.85mm 2.75-3.1mm Better PLA: 1.68-1.78mm, 2.8-2.95mm

ROUNDNESS The ordinary PLA: +/-0.02~0.05mm Better PLA: +/-0.03mm

WATER ABSORPTION The ordinary PLA: High, much bubbles printing at high temperature after the filament opened from seal packaging and exposed to air for a period( like one month or shorter time)

Better PLA: Very low, no bubbles occur when printing even expose to air for over half a year

SURFACE GLOSS The ordinary PLA: Good Better PLA: Normal

TOUGHNESS The ordinary PLA: Not good toughn Better PLA: Type A and C is not good toughness, B is good tough

1) We want to know the good, bad, and ugly with regard to suppliers. Who makes quality filament at a good cost? Who should we avoid?

According to the 3D PRINTERS PRODUCT COMPERISONS

link

ULTIMAKER 2 has the highest review

Maybe we could avoid Mbot Cube company

2) Materials. We want to start doing dual extrusion on a more regular basis. There are a variety of ways we might start using support materials. Which materials do you think we should use? Why do you think we should use them?

I think we should use PLA cause during the past few years PLA material proves to be a good choice and with its own quality. PLA is made from corn, a renewable resource. Unlike petroleum-based plastics, the corn used to make PLA can be grown every year – and can be grown domestically. The PLA resin also requires significantly less energy to make compared to petroleum-based plastics, and PLA bottles are blow molded at lower temperatures than PET and HDPE (high-density polyethylene) bottles, which requires less energy. As a result, PLA is best-suited for products that are oil-based or products that are not negatively affected by moisture vapor transmission. It is also a good option for products that have a relatively short shelf life (12 months or less) and which are not stored in or transported through hot and humid environments. We always suggest that our customers perform their own compatibility tests any time they move into a new resin.

The price of PLA according to different color and size could be found at this link. link

3) Pretend you are shopping for material for your own needs. Who do you choose?

I would probably choose PLA provided by ULTIMAKER 2 company cause it gets the highest review on the website and I want my printed object has a good quality without taking any risk.

Blog 10: designs I think are most reliable

One of the filaments I think is really reliable is PLA. The reasons are as follows. link

PROS

Polylactic acid (PLA), helps to Reduce Greenhouse Gas Emissions Proponents also tout the use of PLA—which is technically “carbon neutral” in that it comes from renewable, carbon-absorbing plants—as yet another way to reduce our emissions of greenhouse gases in a quickly warming world. PLA also will not emit toxic fumes when incinerated.

CONS

1

Because of plastic substitute made from fermented plant starch (usually corn) is quickly becoming a popular alternative to traditional petroleum-based plastics. As more and more countries and states follow the lead of China, Ireland, South Africa, Uganda and San Francisco in banning plastic grocery bags responsible for so much so-called “white pollution” around the world, PLA is poised to play a big role as a viable, biodegradable replacement.

2

PLA Biodegrades Slowly Unless Subjected to Industrial Composting But critics say that PLA is far from a panacea for dealing with the world’s plastic waste problem. For one thing, although PLA does biodegrade, it does so very slowly.

According to Elizabeth Royte, writing in Smithsonian, PLA may well break down into its constituent parts (carbon dioxide and water) within three months in a “controlled composting environment,” that is, an industrial composting facility heated to 140 degrees Fahrenheit and fed a steady diet of digestive microbes. But it will take far longer in a compost bin, or in a landfill packed so tightly that no light and little oxygen are available to assist in the process. Indeed, analysts estimate that a PLA bottle could take anywhere from 100 to 1,000 years to decompose in a landfill.

3

Recyclers Can’t Mix PLA and Other Plastics Another issue with PLA is that, because it is of different origin than regular plastic, it must be kept separate when recycled, lest it contaminate the recycling stream. Being plant-based, PLA needs to head to a composting facility, not a recycling facility, per se, when it has out served its usefulness. And that points to another problem: There are currently only 113 industrial-grade composting facilities across the United States.