User:Zac5060/Blog

Main | About Me | Class Blog

Contents

Blog I: January 22nd, 2014

The Search Through the Thingiverse!

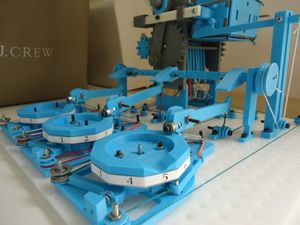

Amazing: Turbo Entabulator, Fully Mechanical Computer

While it requires some springs, pulleys, and rubber bands for full assembly, it has 3 single digit base-10 counters that can process a chain of 10 position punch cards. For fun you can calculate some of the first few digits of the Fibonnaci sequence!

Funny: Provocative Hands

This one needs very little explanation. While it may be terribly immature, I find it extremely funny that this was something someone printed. It makes for the perfect paper holder, desk decoration, or ice breaker at a party. While this design is a little complex, it is clearly able to be built, and a bit of an impressive feat for the overhangs to be able to hold while printing.

Useless: Useless Machine Arm

If you have never seen one before here is an example video but "The Most Useless Machine" is an incredible feat of.... technology I suppose. No matter how many times you flick the switch, its able to come right back and flick if off (until it's batteries run out). That is why I believe that the "Useless Machine Arm" is literally the most useless thing I could find on Thingiverse.

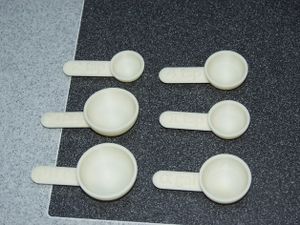

Useful: Measuring Spoons

Have you ever been cooking and just couldn't find that pesky tbsp.... or wait, was it tsp? Well fear no more, print your own! This build comes with all strange shapes and sizes, and has large print letters on the label. Having any size at hand while cooking is extremely useful and ensures that what you are cooking turns out just right. Also, if you are extremely lazy, you'll never have to wash a measuring spoon again!

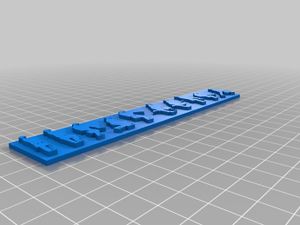

Surprising: The Ministry of Silly Walks

While browsing through Thingiverse I was lucky enough to stumble upon one of my favorite Monty Python skits, The Ministry of Silly Walks. Of all the models I browsed through this was one of the ones I least expected to see.

Blog II: February 1st, 2014

Open Source Ecology (OSE) and its impacts

If you are unfamiliar with what OSE is, they have a video titled Enterprise Plan which outlines the groups goal. The OSE Project is an amazing project that has a goal of giving users the ability to make 50 different types of industrial machines. They believe these 50 machines help to create the modern, industrial civilization that we have today. Its founder Marcin Jakubowski gave a TED talk on the project back in March 2011, explaining that he wants to give people across the world the ability to inexpensively create their own industrial equipment. The equipment they have schematics and designs for range from laser cutters, to bread ovens, and even well drilling rigs. On the very top of their websites list of 50 devices, are a 3D printer and scanner. While their information on 3D printers is somewhat lacking, they show interest, and even refer users to visit RepRap for more information.

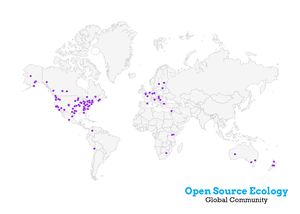

Overall the project seems like a good idea with great intentions. Personally, I believe that the largest threat facing man kind at the moment is overpopulation. Theres is a great video about it by David Suzuki that outlines why it is such a quickly approaching threat. Without the proper buffers, the fallout that will come from overpopulation when earth reaches maximum capacity could be catastrophic. Projects like this are a step in the right direction to helping solve some of earths population issues by increasing the overall amount of resources available for people. Access to industrial equipment increases the ability to create goods that help sustain human life. Giving farmers, construction workers, and laborers the ability to inexpensively industrialize their labor means greater productivity and efficiency. It also means that the workers can reap greater benefits to help sustain themselves and their surrounding communities. Many parts of Africa, South America and Southern Asia still rely on out dated agricultural methods, and occasionally suffer from famines due to this. With industrial equipment, the efficiencies of these areas of the world could surge, supplying the regions with a much needed volume of goods.

On top of providing industrialization to the third world, this website would be a great apocalypse kit. Let me paint you a picture:

China and America have finally gone to war due to land claims between Japan and China over a tiny rock in the middle of the East China Sea (sounds dumb right?). China mistakes a flock of geese on radar for an ICBM and launches their arsenal. America follow with a barrage of their own. India and Russia, having nothing better to do, launch their stockpiles. Not long after everyone is pushing the button and the Doomsday Clock strikes midnight. The surface of the earth becomes an arid, slightly radioactive wasteland in a sort of wild west, Fallout, Mad Max kind of way. A group of survivors scouring the wastes manage to dig up an old laptop out of the dust. In the laptop is a CD of OSE, and while non of them have specialized skills in farming or survival, with that disk they rebuild society (roll credits)

The above is a long, drawn out waste of text, but it makes my point that the OSE project is basically a civilization startup kit. All of the schematics and diagrams can be created by most people with the ability to think and create extremely useful machines. While it will hopefully never be needed on earth, it would be neat to see people use something like OSE to colonize planets, moons and asteroids throughout the solar system and galaxy. Even though it is still science fiction, I would love to see a future where colonists land on a new planet and use open source technology to immediately begin creating their own habitat.

On the down side, some of the projects still require moderately expensive equipment to make, and some of the materials used are not the easiest thing to get your hands on. Also one of their largest challenges could be actually spreading their plans to the far reaches of the world where computers and internet are hard to find. On top of this the projects are still in developmental stages, so some of the devices may not have the longest life cycle or overall strength/refinement. Also, while I see the website as having little liability for people making their machines, if someone were to follow their schematics and build a machine that would injure or kill them, I could see a sue happy person taking OSE to court. As grandpa always used to say, "it only takes one idiot to ruin something good for everyone".

Recently The New Yorker published an article titled The Civilization Kit, which goes in depth on the ESO project and Marcin's work. The article was critical towards his work, what he has actually accomplished, and the project's feasibility. It also notes the poor living conditions on his farm and his relationships with his fellow workers/supporters. While this article is very harsh it brings up some very good points about the project. While the project is extremely flawed, it is a startup that is still in its infancy. They are low on cash and trying to do some pretty amazing things at the same time. Marcin posted a response on the OSE wiki site defending his project. He defends himself and his work, claiming not to be the estranged commune that Emily Eakin writes about in her article. He also goes on to defend his mission statement and explain how their operation is limited by money. While I can see many valid point in The New Yorker article, I also understand that this project is still developing and trying to construct its base. It will need a lot of work to become a fully realized, but hopefully, its core idea will remain pure and achieve its overall purpose of helping the world.

As far as PSU is concerned, I fell like a club or organization could definitely take root that follows the ideology and goals that OSE has set forth. With the amount of agricultural, and engineering majors around campus, a club where students can come together and create designs for complex mechanical systems would be educationally beneficial for students and foster development and innovation on such machines. Faculty in the agricultural, engineering, or even computer sciences departments could possibly be interested in exploring ways to create complex machines for the common man in hopes of performing research with them. On top of all of this, the on campus ROTC and military programs may be interested in such a club. In remote areas of the world where the military operates, they are sometimes required to use heavy machinery to complete a variety. The formation of a club could allow them to use students to innovate new methods and designs to be built or repaired. With new more robust designs, the military could have workers repair machinery on site and more quickly, and reduce delays.

Blog III: February 9th, 2014

Kansas Teen Uses 3D Printer to Make Hand for Boy

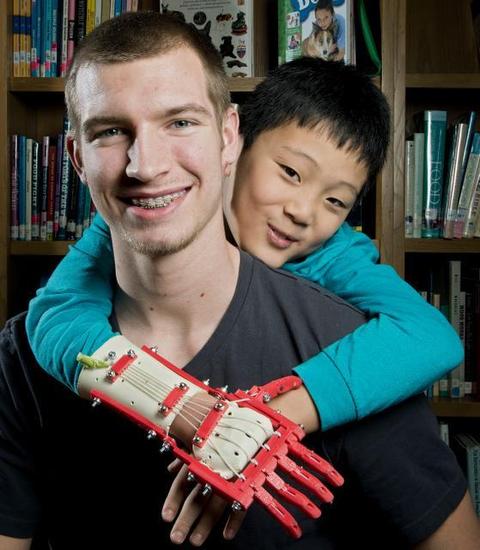

This article was published on January 31st in The Kansas City Star newspaper.

Who created this design and when/where was it done?

Ivan Owen, a designer an professional artists from Washington State, and Richard Van As, a South african carpenter, designed the original 3D Robohand when Van As lost a finger and portions of three other fingers in a workshop accident. Van As went to the internet looking for a solution and came in contact with Owen. The two began online communications and began working to create a finger replacement for Van As. A South African Mother then found their online communications and asked if the two could build a prosthetic hand for her son. Their original prototypes were made from metal, but they soon switched to working with 3D printers to be able to create prosthetics that could be easily printed and allow adaptations for each user. Work for this project began in November of 2012, and the first 3D printable version was released in January 2013.

If you wanted to make one, where would you go to get it?

The 3D printing files for the hand can be found on the Thingiverse website, and can be seen using this link. Its appears to be a fairly simple yet robust design and as the article discusses, it is adaptable depending upon the extent of your hand injury. The only other parts necessary are the strings to activate the fingers, the fasteners, and the sheaths for the wrist and knuckle areas.

How many news articles can you find which reference this technology?

There are quite a few articles referencing the design made by these two men, many of which can be found by performing a simple google search. There are even more referencing 3D printing's ability to make prosthetics. Included below are some example articles for anyone who wishes to read more about these devices:

Robohand: How cheap 3D printers built a replacement hand for a five-year old boy

These 3D printed prosthetic hands can be made for just $5~$1000

3-D Printer Brings Dexterity To Children With No Fingers

Man Makes 3D Printed Prosthetic Hand For Son For Only $10

Two Makers Create a $150 Open Source 3D Printed Prosthetic

Blog IV: February 15th, 2014

Looking From Another Mans Shoes, OSE Revisited

Team Super Awesome's Response to OSE

Looking through my fellow teammates responses, I can say that some of them I agree with, some I disagree with, and some I just hadn't thought quite as much as. Nathan saw the project as a doorway for small scale farmers to come back into today's market of mega farms. With the recent boom in organic foods, and free range meats, cheaper farming machinery would definitely be a much needed boost. Jess saw the project as promising, but has some issues with it. She states that everyone creating their own equipment would run larger companies out of business over time and it would take a great deal of skill to create such prjects. While I see her point as completely valid I don't believe it would completely deter people from buying products of larger companies. I believe it would help smaller producers get a foot in the door, but when it comes to larger scales, the efficiency of specialized labor would keep the larger companies in business. Sam was pretty rough on the New Yorker columnist, and discussed how she was disconnected from the ideology of the project and the plight of the common man. I had not really considered this thought, and reviewing her article once more, completely see where Sam is coming from. While some of her criticisms have a core of truth, the majority of her article reads off as petty and rude. Sadly Ben had not written a blog about the OSE project, but from what I remember that was the week he had traveled to the far reaches of the Atlas Mountains in the north of Africa to hunt the vicious, blood-thirsty, and deadly sand cats.

Classmates of Dutiful Intelligence's Response to OSE

Tom's opening statements about OSE are something I had not even though of at all when I wrote my post, and I must say he is extremely correct. He states that "You could find out how to make these types of projects by doing some internet searching. Additionally, these designs would be superior as they have probably been tested and refined by multiple people." After searching the internet for a few minutes, I found he was completely correct. It brings me back to a statement I made above about Jess' blog post, when I state it is far more efficient to have specialized workers in their respective fields working. But it also makes me think of what inspires creation, and that is an understanding of many systems and how to relate them to one another. While I agree it is not the most efficient for farmers to create all of their own equipment, for some entrepreneurs out there I believe a project like this will spawn creation and original thought.

Donago had very negative impressions of the OSE project. He states that tractors are too complex of equipment to have open source builds for, unlike 3D printers which are shared in open source forums such as this site. He also states that in larger scales it lacks efficiency, which I completely agree with. While I also agree that tractors are complex, when it boils down to it so are 3D printers. I believe the project is meant for smaller scale start ups and not meant to compete with the heavy hitters of the industry. Kevin gave a rather fair critique of the New Yorker article, and noted on its pettiness towards the projects but also noted towards the articles mention of the projects major flaws. He was correct in pointing out that the people working on the project are more enthusiasm then skill, which makes sense because the people who are very skilled at making tractors or bricking machines probably work at John Deere or at Belden. Anthony states that he does not believe that OSE is a civilization starter kit. He takes the build times with some skepticism and is reserved in the total ability of the project which I understand and appreciate. He is completely right to think that the project is not some magical thing to come along and re-invent the wheel, but personally I still believe it is a step in the right direction. Lastly I read Nam's response to OSE. First off shout out to Nam for the awesome About Me Section, I thought it was pretty funny. I read Nam's idea on how to start an OSE chapter at Penn State and his response was similar to mine. I thought he made extremely valid points about the projects feasibility at Penn State, but also noted on how it being such an agriculturally minded community would help start a project.

Blog V: February 22, 2014

A Journey Through the Past

I figured I would start my media search with the year that I came to Penn State, back in the fall of 2010, to see how much 3D printing, and its community has evolved over my college tenure. All of the articles or information used for this blog was found on the SCRUG media page.

November 2010 : It Will be Awesome If They Don't Screw It Up

This article written by Michael Weinberg centers on 3D printing and how it relates to intellectual property. He begins with delving into the work spaces (garages, basements, workshops, etc.) that 3D printing is taking root. He compares the emerging 3D printing world to be similar to the computers world of the early 90's. After some explanation of what 3D printing is he dives into intellectual property. He talks about how after patenting an object, reproduction of that product without the creators consent is infringement. With 3D printing on the rise, he expects a boom in "innocent" patent infringements. Where owners of 3D printers create a part for personal use not realizing it is patented. He also talks about how 3D printer owners will be copying products purposefully with the intention of avoiding purchase of them. To this day this is something that is commonly address when people mention 3D printing. Whether intentional or not, 3D printing comes with a responsibility of the owner to know when they are infringing on a patent. Personally, I believe that as long as the person printing is not selling the printed object for resale or mass production, personal use is something they should feel free to indulge in when it comes to printing. Overall Michael wrote an excellent article that is still relevant to printing even 4 years later. When it comes to intellectual property and 3D printing I am sure it will be debated in many years to come.

January 2011 : 3D Printing, Now in Titanium

Did you ever wish you could print out those titanium hub caps you've always wanted? What about printing out a shiny new titanium necklace for that girl down the block that makes you feel funny? Well dream no more, you can now print whatever you can think in titanium (back in 2011). Written by Charlie Sorrel, this article introduces a new printing method developed by I.Materialize called Direct Metal Laser Sintering. The process uses a high power laser to sinter the metal into the proper shape. Sadly the process is expensive, using one cubic centimeter costs 125$. Despite its large price tag, it is a step towards increasing the catalog of what is printable and another application for the technology to be used in.

August 2011 : All-Star Lineup Invests in MakerBot

Bre Pettis takes readers on an inside look at a 10million dollar investment that is planned to help grow the company and develop the MakerBot product line. I saw this article as a significant step into making a wider range of low end printers available to the general public. MakerBot is widely known as one of the leading manufacturers in 3D printers for home use, and with a larger investment pool will be able to develop better products, and create larger manufacturing capabilities. Hopefully as the business grows it will be able to foster more education and technological developments in printers not only today but down the road.

January 2012 : Physibles now a Section on The Pirate Bay

Avast ye mateys, prepare to set sail for adventure, and printing on the high seas of the internet. In January 2011, the infamous torrent site, with the goal of sharing all media freely on the internet started as section devoted to sharing files for 3D printers. While affiliation with The Pirate Bay may land you in hot water, or on a movie studios mailing list, it also is a huge source for sharing files between a large volume of people. Earlier in this blog I commented on an article focused on intellectual property, and two years later the issue emerges again with the pirate bay. While there may be some issues with infringement of intellectual property with the emergence of Pirate Bay physibles, I believe it is a great way to share prints and ideas between many users.

November 2012 : 3D Printers Could use Moon Rocks, Say Scientists

This BBC article looks at the possibility of using non terrestrial material as a 3D printing substrate.

June 2013 : 3D Printing Tiny Batteries For Tiny Robots, Medical Devices